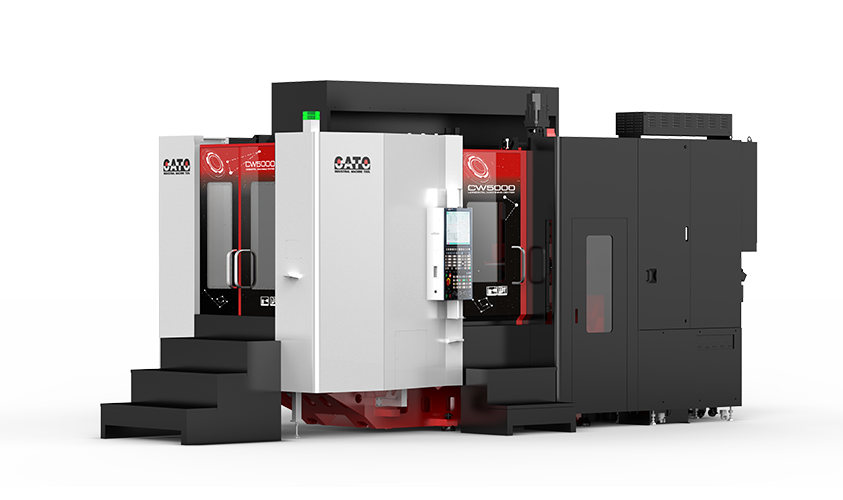

Policy-Driven Equipment Upgrade: CATO's CW5000 High Speed Horizontal Machining Center Boosts Three Major Industries

Release time:

2025-10-16

Author:

CATO

Source:

Internet

Six ministries and commissions issued the "Work Plan for Stabilizing Growth in the Machinery Industry", promoting the industry's operating income to achieve an average annual growth rate of 3.5%. Against this backdrop, the machining demand in the three major industries of construction machinery, aerospace and new energy vehicles has surged. CATO's CW5000 4-axis horizontal machining center, with its high-rigidity structure, high-precision design and efficient production capacity, can accurately adapt to the machining of key components in multiple industries, becoming the preferred choice for enterprises' equipment renewal and helping the high-quality development of the industry.

With six ministries and commissions jointly issuing the "Work Plan for Stabilizing Growth in the Machinery Industry", the construction machinery, aerospace and automotive industries have ushered in a new round of development opportunities. CATO's CW5000 4-axis high speed horizontal machining center provides key technical equipment for industrial upgrading with its high rigidity and high-precision machining capabilities.

Recently, the Ministry of Industry and Information Technology and five other ministries and commissions jointly issued the "Work Plan for Stabilizing Growth in the Machinery Industry (2025-2026)", clearly proposing to promote the machinery industry's operating income to achieve an average annual growth rate of about 3.5% from 2025 to 2026 and a total scale exceeding 10 trillion yuan through measures such as equipment renewal and technological transformation. Driven by this policy dividend, key industries including construction machinery, aerospace and automotive manufacturing are experiencing a new wave of equipment renewal and industrial upgrading.

01 Industry Embraces Policy Opportunities, Equipment Renewal Demand Released

The issuance of the "Work Plan for Stabilizing Growth in the Machinery Industry" has brought a clear development direction for the machine tool industry. The plan specifically emphasizes promoting major technological transformations in manufacturing and activating the stock markets such as industry, railways, agricultural machinery and medical care.

Currently, the machine tool industry is showing an accelerating trend of domestic substitution. Domestic machine tool enterprises have achieved breakthroughs in import substitution in fields such as new energy vehicles and consumer electronics by virtue of their accurate grasp of local demand and agile services.

Meanwhile, the continuous improvement of the numerical control rate has brought incremental opportunities for CNC machine tool enterprises. Driven by policy guidance and industrial upgrading, the numerical control rate is accelerating, bringing greater market increments for CNC machine tool enterprises.

02 Prominent Opportunities in Three Major Industries, Sustained Growth in Machining Demand

After several consecutive years of decline, the construction machinery sector achieved a significant recovery in the first half of 2025, with a year-on-year growth of about 170%. With the continuous advancement of infrastructure construction, the demand for machining high-precision transmission components and hydraulic parts in the construction machinery industry continues to grow.

As a representative of high-end equipment manufacturing, the aerospace industry has extremely high requirements for the machining of complex components. Key parts such as impellers, closed impellers, blisks, fan disks and aero-engine casings all require high-precision 5-axis machining capabilities.

The automotive industry, especially the new energy vehicle sector, has grown rapidly, with a year-on-year increase of about 60% in the first half of 2025. The demand for machining key components such as new energy battery casings, transmission bearings and gearbox casings continues to rise, putting forward higher requirements for machining efficiency and precision.

03 CATO CW5000 High Speed Horizontal Machining Center: Born for High-Precision Machining

In response to the growing demand for precision machining in various industries, CATO has launched the CW5000 4-axis high speed horizontal machining center, which provides an ideal machining solution for the three major industries with its high rigidity and high precision.

High-Rigidity Structure Enables Stable Machining

The CW5000 adopts an integrally formed base and a positive T-structure design for the X-axis high and low rails to ensure high rigidity of the machine tool. The connection between the worktable body and the pallet is tightened by 4-point conical platforms with a pallet clamping force of 73.2kN, and the indexing table maintains stable machining during heavy cutting by using a worktable clamping force of 85.2kN.

The inclined design of the X-axis maintains the height difference of the installation planes of different X-axis linear guides, ensuring both high rigidity and high-speed and high-precision positioning. When the X-axis and Y-axis move, the reinforcing ribs improve the rigidity of the machine tool bed, thereby ensuring machining stability.

High-Precision Design Guarantees Machining Quality

To achieve high-precision machining, the CW5000 has been optimally designed in multiple key systems. The built-in spindle/electric spindle greatly reduces vibration during high-speed operation, achieves good surface finish, and thus significantly extends tool life.

The spindle temperature control system circulates cooling fluid through the spindle bearings and spindle box to effectively reduce the thermal change of the spindle. The hollow cooling technology for the X, Y and Z-axis ball screws realizes the circulation of cooling fluid for temperature management through the cooling unit, ensuring stable machining precision under continuous high-speed operation.

Efficient Production Capacity Meets Mass Demand

The CW5000 has a 3-axis rapid traverse speed of 60m/min and an axial feed acceleration of 0.6G. The high-speed and high-torque electric spindle reduces the spindle acceleration and deceleration time, greatly shortens non-machining time and improves machining efficiency.

Equipped with a 50-tool magazine and a tool change time of 7 seconds (tool-to-tool), the equipment ensures maximum efficiency during continuous machining, making it particularly suitable for the machining of parts that require alternating use of multiple tools, such as new energy battery casings and gearbox casings.

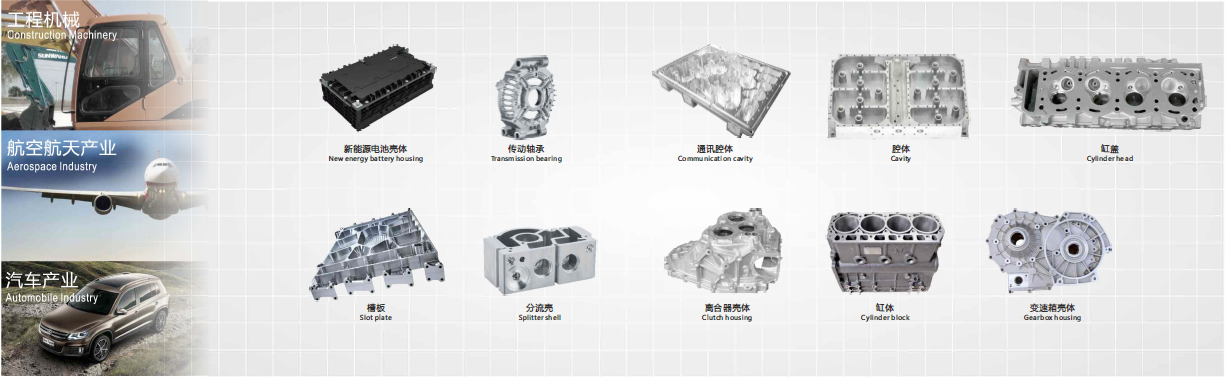

04 Typical Machining Cases: Application Display in Multiple Industries

In the construction machinery field, the CW5000 can efficiently machine key components such as transmission bearings, cylinder blocks and cylinder heads, and its high-rigidity structure ensures stability under heavy cutting conditions.

For the aerospace industry, the equipment is good at machining various cavities and complex structural parts, meeting the extremely high requirements for part precision and reliability in the aerospace field.

In automotive manufacturing, especially new energy vehicles, the CW5000 can batch process key components such as new energy battery casings, clutch housings and gearbox casings, providing equipment support for the upgrading of the automotive industry.

With the implementation of the machinery industry's steady growth policy, the demand for equipment renewal in the construction machinery, aerospace and automotive manufacturing fields will continue to be released. CATO's CW5000 4-axis high speed horizontal machining center is becoming the preferred equipment for many manufacturing enterprises due to its high rigidity, high precision and high efficiency.

05 Welcome to contact CATO to learn how the CW5000 high speed horizontal machining center can create value for your enterprise!

▷ Email: hujuzhen@catocnc.com

▷ Phone: +86 138-2920-2050

▷ For details, visit: https://en.catocnc.com/product/60.html

Key words:

Previous Page

Previous Page:

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638