CATO CBS 650 5-Axis Bridge-Type Machining Center: Leading a New Era of Aerospace Precision Manufacturing with Hardcore Technological Breakthroughs

Release time:

2025-10-08

Author:

CATO

Source:

Internet

CATO has launched the CBS 650 5-axis bridge-type machining center. Leveraging hardcore technologies such as direct drive of X/Y-axis linear motors and independently developed HSK series electric spindles, along with diverse CNC systems including Siemens, it achieves high-precision machining. Its bridge-type high-rigidity structure is suitable for heavy cutting, and the A/C-axis torque motor direct-drive cradle ensures stability, enabling the machining of complex aerospace parts. Benefiting from favorable current industry policies, CATO is expanding production capacity. This equipment enhances the competitiveness of domestic high-end equipment and supports the upgrading of aerospace manufacturing.

As the global manufacturing industry rapidly moves towards higher precision and efficiency, 5-axis simultaneous CNC machine tools have become core equipment in the aerospace sector. As an outstanding representative of domestic high-end equipment manufacturers, CATO (Guangdong) Co., Ltd., relying on its independent R&D capabilities and technological innovation strength, has launched the CBS 650 5-axis bridge-type machining center, which is bringing innovative production processes and efficiency improvements to aerospace and high-precision parts manufacturing.

01 Technological Breakthroughs: Linear Motor Drive and Independent Core Systems

The CATO CBS 650 5-axis bridge-type machining center represents the advanced technological level of China’s current high-end CNC machine tools. The equipment adopts high-performance linear motor direct drive technology, and the X/Y axes are equipped with a high-precision linear scale feedback system, ensuring ultra-high precision machining capabilities.

In terms of CNC systems, CATO provides multiple options: including Heidenhain TNC 640, the company’s independently developed C80 Plus system, and Siemens Sinumerik One as the standard configuration, providing users with a stable and reliable control platform.

Linear motor direct drive technology eliminates the backlash issue in traditional transmission, providing higher system bandwidth and better system performance. These system configurations enable the equipment to easily meet the high-precision machining requirements of complex curved surfaces in the aerospace field, significantly shortening the production cycle and improving machining efficiency.

02 Structural Innovation: Bridge-Type High-Rigidity Design and Independently Developed Spindle

The CBS 650 adopts an innovative bridge-type high-rigidity structural design. The overall structure is stable with high rigidity, capable of withstanding large working loads. This design ensures that the three axes are not affected by the size and weight of the workpiece in terms of machining efficiency during high-speed acceleration and deceleration movements, and guarantees the stable performance of the equipment under heavy cutting conditions.

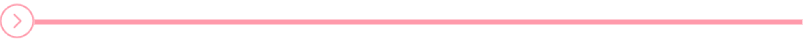

The core component of the equipment—the spindle system—is also independently developed and manufactured by CATO. It adopts HSK series built-in electric spindles (HSK-E40/HSK-A63/HSK-A100), and cools the motor and front/rear bearings through forced cooling, ensuring stable precision during high-speed and long-term machining.

CATO has mastered core technologies and possesses spindle design, manufacturing, and assembly capabilities. The constant temperature and humidity workshops and refined modular production model ensure that the spindle has the characteristics of high rigidity, high speed, high power, high torque, and high reliability.

03 Core Components: Torque Motor Direct Drive and Precision 5-Axis Cradle

The A/C axes of the CBS 650 are equipped with a precision 5-axis cradle independently developed by CATO, which adopts torque motor direct drive technology. This realizes backlash-free and wear-free transmission, enabling long-term maintenance of high-precision machining.

Torque motor direct drive is the current development trend of high-end machine tools. Frameless torque motors allow the machine structure design to no longer be restricted by the motor housing, integrating the motor seamlessly into the machine design. This design eliminates the backlash issue in traditional transmission, providing higher system bandwidth and better system performance.

Compared with traditional servo motors, frameless torque motors are measured by output torque and have advantages such as compact structure, higher torque per unit volume, obvious mute effect, and lower maintenance requirements. These characteristics enable the CBS 650 to achieve higher precision and stability when processing complex parts in the aerospace field.

04 Aerospace Applications: An Ideal Solution for Complex Part Machining

In the aerospace field, the CATO CBS 650 performs excellently, capable of efficiently processing complex curved surface parts such as impellers, closed blisks, integral blisks, and fan blisks, as well as key components including aero-engine casings, casing parts, spiral parts, and turbine parts.

The aerospace field has extremely strict requirements for the machining of precision components. Parts often have characteristics such as complex curved surfaces, high precision requirements, and difficult-to-machine materials. The 5-axis simultaneous machining capability of the CBS 650 enables high-precision machining of complex curved surfaces without multiple clamping, greatly shortening the production cycle and improving machining efficiency.

Linear motor direct drive technology ensures high precision and stability when processing aerospace structural parts, meeting the strict requirements of the aerospace industry for part quality. The equipment’s high-rigidity structure and high-precision control system ensure that the machining precision requirements of parts are met.

05 Industry Background: New Development Opportunities for High-End CNC Machine Tools

Currently, China’s industrial machine tool industry is ushering in unprecedented development opportunities. According to industry reports, the market size of China’s CNC machine tools reached 432.5 billion yuan in 2024, with a year-on-year growth of 5.75%. National policies supporting the high-end equipment manufacturing industry also provide strong guarantees for the development of the industry.

As the "tool for manufacturing tools" and the "foundation for self-reliance," industrial machine tools are at the core hub of the modern industrial system and a strategic basic industry related to national security. With the surge in demand for the machining of complex precision parts in high-end manufacturing industries such as aerospace and new energy vehicles, traditional CNC machine tools can no longer meet the requirements of high precision, high efficiency, and flexible production.

Against this backdrop, CATO has invested approximately 516 million yuan in Yinchuan, Ningxia, to build a high-end precision industrial machine tool manufacturing and smart factory project. Covering an area of 129 mu (about 86,000 square meters), the project plans to construct 50,000 square meters of workshops, which will provide stronger support for the development of China’s high-end manufacturing industry.

06 CATO: A Technologically Leading High-End Equipment Manufacturer

As a leading domestic high-end equipment manufacturer, CATO has always been committed to technological innovation and product R&D. The company has complete spindle design, manufacturing, and assembly capabilities, realizing independent and controllable core technologies.

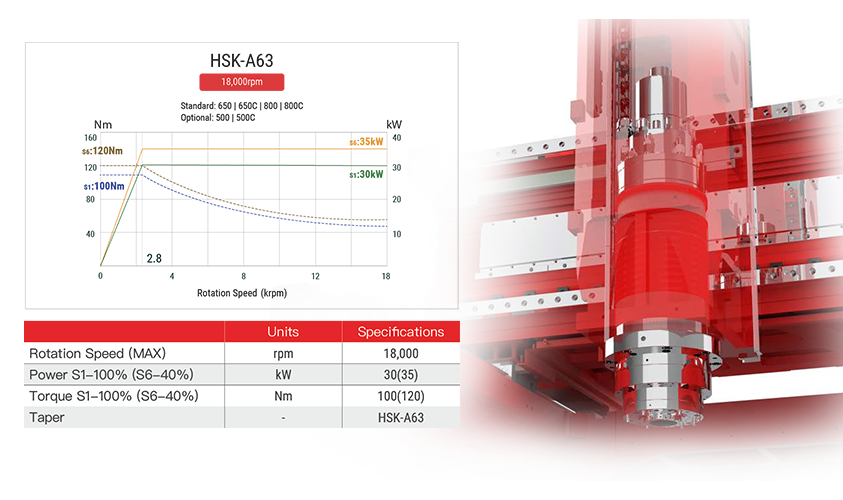

Facing the transformation and upgrading of the global manufacturing industry, CATO continues to increase R&D investment and launch a series of high-end CNC equipment that meets market demands.

The company adopts constant temperature and humidity workshops and a refined modular production model to ensure the stability and reliability of products. CATO’s products feature high rigidity, high speed, high power, high torque, and high reliability, and have significant competitiveness in both domestic and international markets.

As China’s manufacturing industry continues to move towards high-quality development, the technological breakthrough of the CATO CBS 650 5-axis bridge-type machining center not only enhances the international competitiveness of China’s high-end equipment manufacturing industry but also provides strong technical support for the aerospace industry.

The rise of domestic high-end equipment is changing the long-standing pattern of relying on imports, providing a solid guarantee for the independent and controllable development of China’s manufacturing industry. In the future, CATO will continue to deepen technological innovation and provide higher-quality high-end equipment and solutions for global manufacturing customers.

▷ Email: hujuzhen@catocnc.com

▷ Phone: +86 138-2920-2050

▷ For details, visit: https://en.catocnc.com/news_details/38.html

Key words:

Previous Page

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638