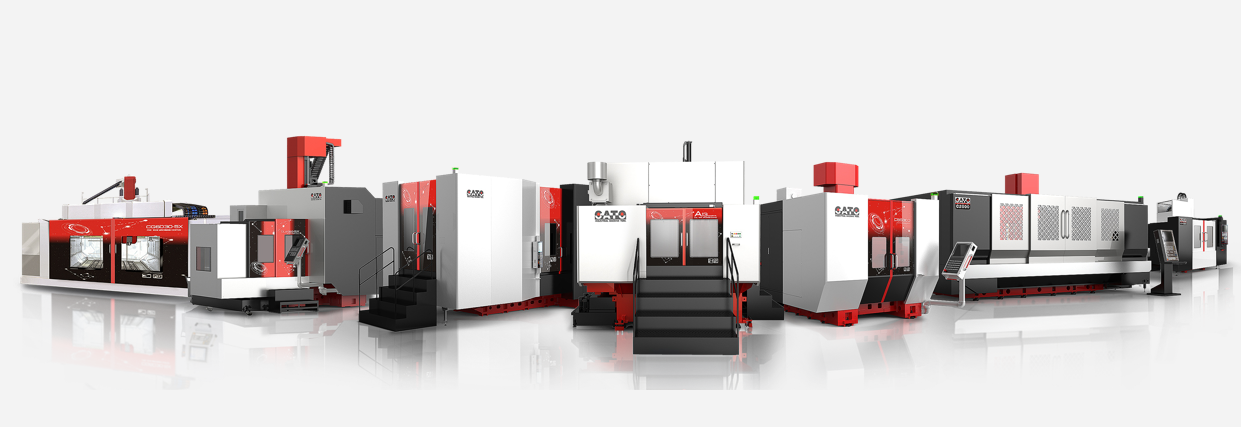

Unlock Precision: How CATO CBS 650 Five-Axis Machining Center Empowers Aerospace Innovation

Release time:

2025-10-09

Author:

CATO

Source:

Internet

CATO’s CBS 650 five-axis bridge-type machining center meets high-tolerance needs in aerospace/medical sectors. It has a rigid bridge structure, X/Y linear motor drive, self-developed spindle, and A/C torque motor table, cutting setup time and ensuring precision for complex parts. Partner CATO for custom support; contact for consultation.

In the realm of advanced manufacturing, where complexity meets uncompromising quality, the five-axis machining center has become the cornerstone of progress. Discover how CATO CBS 650 is setting new benchmarks.

Meta Description: Explore CATO CBS 650 five-axis machining center. Engineered for aerospace & high-precision industries, it delivers unmatched accuracy for impellers, blisks, engine casings & more. Get your custom solution today!

As global demand for complex, high-tolerance components soars, the five-axis machining center has transitioned from a luxury to a necessity in industries like aerospace, medical, and energy. CATO Precision Machinery (Guangdong) Co., Ltd. answers this call with its technologically advanced CBS 650 Five-Axis Bridge-Type Machining Center, a machine designed to tackle the most challenging manufacturing tasks with exceptional precision and efficiency.

Why a Five-Axis Machining Center is a Game-Changer

Unlike conventional three-axis machines, a five-axis machining center allows for simultaneous movement along five different axes. This capability enables the machining of complex contours, undercuts, and deep cavities in a single setup. The benefits are transformative:

Reduced Setup Time: Complete machining from multiple angles in one clamping.

Higher Accuracy: Eliminates cumulative errors from re-positioning the workpiece.

Superior Surface Finish: Optimal tool orientation maintains perpendicular cutting and constant surface speed.

Ability to Process Complex Geometries: Ideal for prototypes, molds, and intricate parts like impellers and turbine blades.

CATO CBS 650: Engineered for Peak Performance in Demanding Applications

The CATO CBS 650 is not just a five-axis machining center; it is a comprehensive solution built for rigidity, speed, and microscopic accuracy.

1. Unmatched Structural Rigidity with Bridge-Type Design

The core of the CBS 650 is its robust bridge-type structure. This design ensures extreme stability, allowing the X, Y, and Z axes to perform high-speed movements and accelerations without being affected by the size or weight of the workpiece. This inherent rigidity is crucial for heavy-duty roughing operations while maintaining the stability needed for ultra-fine finishing.

2. High-Speed Precision with Linear Motor Drive

The X and Y axes utilize high-performance linear motor direct-drive technology, coupled with a high-precision glass scale feedback system. This advanced combination eliminates mechanical backlash, providing exceptional positioning accuracy and smooth motion at high velocities, which is essential for achieving the tight tolerances required in aerospace components.

3. Core of the Machine: Our Self-Developed Spindle System

At the heart of our five-axis machining center lies CATO proprietary, internally-built motorized spindle. Available in HSK-E40, A63, and A100 interfaces, this spindle is engineered for high rigidity, high RPM (up to 24,000), and powerful torque. A forced cooling system for the motor and front/rear bearings ensures thermal stability, guaranteeing consistent precision even during prolonged high-speed machining cycles. Manufactured in a temperature and humidity-controlled cleanroom, our spindles represent the pinnacle of in-house core competency.

4. True 5-Axis Capability with a Direct-Drive Rotary Table

The CBS 650 features a self-developed A/C axis precision tilting table driven by torque motors. This direct-drive technology offers:

No Backlash & No Wear: The absence of mechanical transmissions like worm gears ensures consistent accuracy over the machine's entire lifespan.

High Dynamic Response: Extremely fast acceleration and deceleration for reduced non-cutting time.

Low Noise and Vibration: Enables smoother operation and higher quality surface finishes.

Key Applications: Solving Real-World Manufacturing Challenges

The CATO CBS 650 five-axis machining center is the ideal partner for manufacturing critical components in high-tech sectors:

Aerospace: Perfect for machining impellers, closed impellers, blisks, fan disks, engine casings, and structural components from tough materials like titanium and Inconel.

Medical: Capable of producing complex surgical instruments, implants, and medical device components with the required high level of cleanliness and precision.

High-Precision Engineering: An optimal solution for prototypes, complex fixtures, and components for the energy and automotive racing industries.

Partner with CATO, Your Expert in Advanced Machining

Choosing CATO means more than buying a machine; it's investing in a partnership. With years of expertise in designing, manufacturing, and assembling our core components, we offer unparalleled support and custom solutions tailored to your production needs.

Are you ready to enhance your manufacturing capabilities and take on the most complex projects with confidence?

> Contact CATO Today to Request a Personalized Consultation and Quote

▷ Email: hujuzhen@catocnc.com

▷ Phone: +86 138-2920-2050

▷ For details, visit: https://en.catocnc.com/news_details/38.html

Key words:

Previous Page

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638