2025 Mid-Autumn and National Day Joint Celebration: Shutdown Maintenance Guide!

Release time:

2025-09-28

Author:

CATO

Source:

Internet

As the hands of time turn to the golden month of October, the warm family reunion of Mid-Autumn Festival and the joyous celebration of National Day meet perfectly. We are about to embrace a special holiday filled with feelings of family and country. To help you better plan this wonderful time and properly arrange your travel and reunions, we have specially prepared this detailed holiday guide to accompany you through a peaceful, joyful and safe extended holiday.

When the hands of time turn to golden October, the warm family reunion of the Mid-Autumn Festival and the grand celebration of the National Day meet perfectly, and we are about to embrace a special holiday filled with feelings of family and patriotism. To help you better plan this wonderful time and properly arrange your travels and reunions, we have specially prepared this detailed holiday guide to accompany you through a peaceful, joyful, and safe extended holiday.

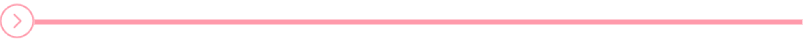

In accordance with the notice from the General Office of the State Council and combined with the actual operation of our company, this year’s Mid-Autumn Festival and National Day holidays are connected, forming a 6-day "Golden Week" that allows you ample time to enjoy family reunions and travel fun.

Holiday Period:October 1, 2025 (Wednesday) – October 6, 2025 (Monday), totaling 6 days off. Work will resume normally from October 7, 2025 (Tuesday).

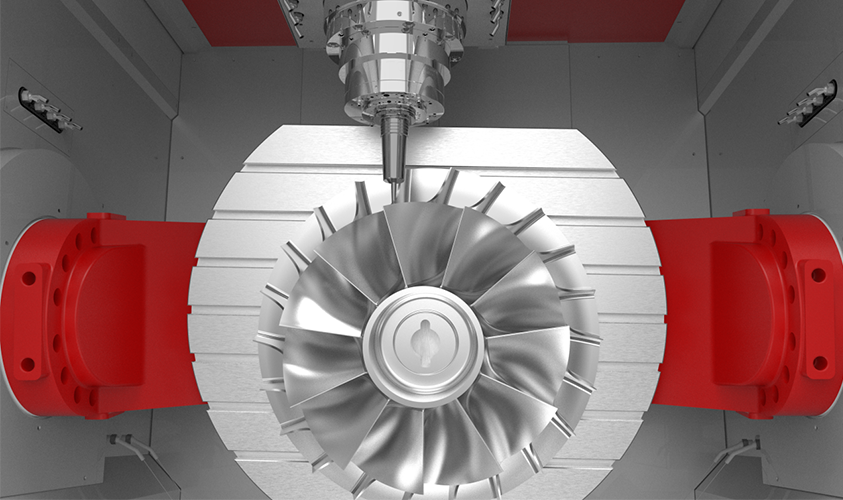

01. Maintenance of the Lubrication System

Before shutdown, manually press the oil injector to ensure all guideways are coated with lubricating oil to prevent rusting.

When using the equipment for the first time after the holiday, manually press the oil injector to apply oil (press more than 3 times) – only move each axis after all guideways are coated with lubricating oil.

Check if the oil quality of the oil injector has deteriorated, if the pressure meets the requirement, and if each axis is properly lubricated.

02. Maintenance of the Pneumatic System

Ensure the air supply is in good condition, free of impurities, and dry.

Drain the moisture from the filter.

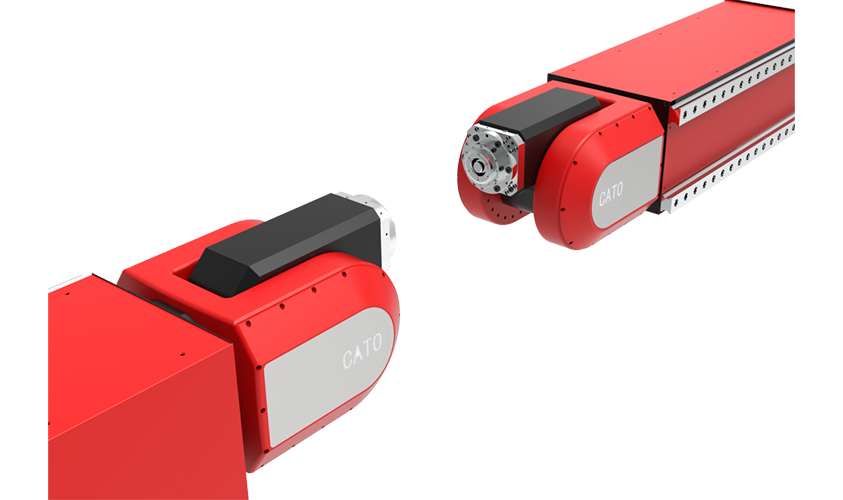

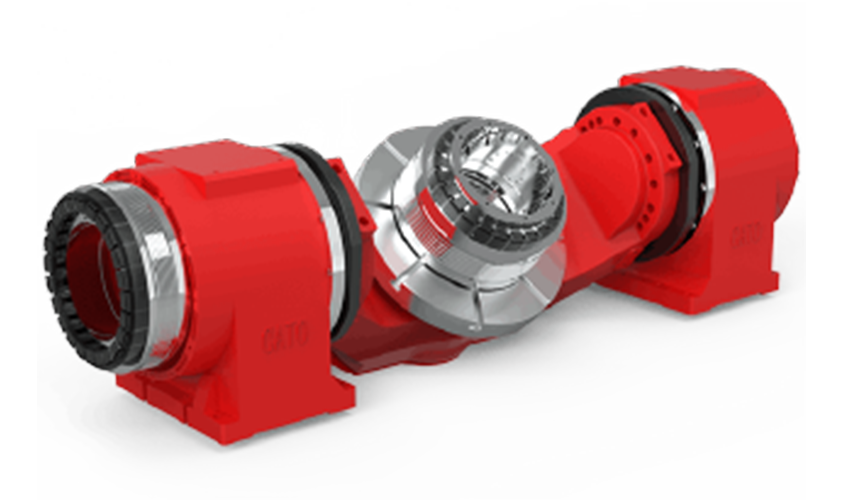

03. Maintenance of the Spindle

Check if there is debris in the spindle’s internal taper hole and if the taper surface is damaged; remove any debris and apply grease.

Before the spindle rotates, ensure the tool clamping/unclamping function and the cooler are working normally.

If the machine is not in use for more than 2 hours, keep the spindle in an empty tool state.

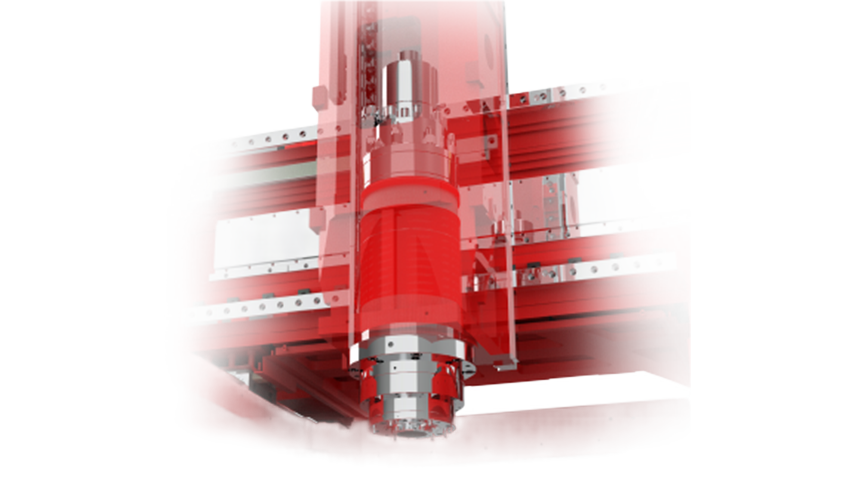

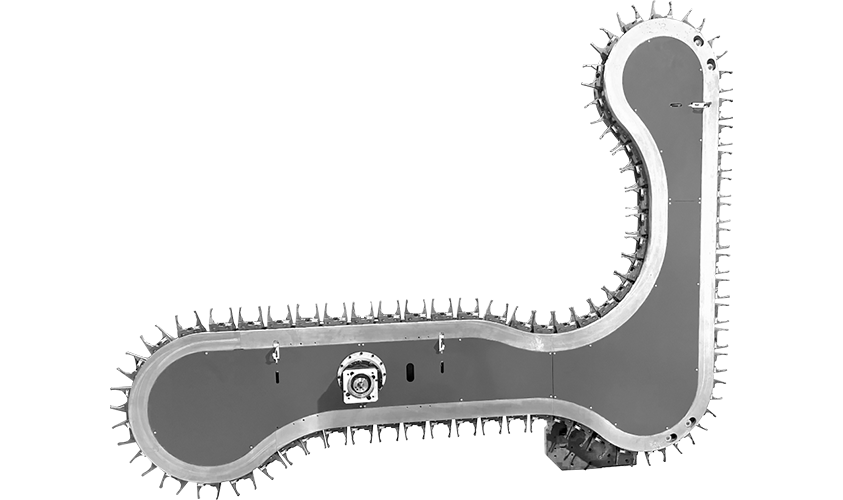

04. Maintenance of Mechanisms

Before shutdown, move each axis to the mid-position to keep all axes in a stroke-relaxed state.

Clean the interior of the 3-axis mechanism, tool magazine, and 4th/5th axes.

Apply grease to exposed working surfaces (e.g., worktable, spindle, protective cover) to prevent rusting.

Run the tool magazine with empty tool cups for tool changes; install tool holders for tool changes only after confirming normal operation.

Use the handwheel to move each axis to the maximum and minimum strokes, and check for abnormal noise or operation.

05. Maintenance of the Cooling System

Check the oil level and viscosity in the oil tank, and decide whether to add or replace with new oil.

Clean the air filter on the spindle oil cooler and check if the cooling medium is insufficient.

Timely clean the water tank and filter bag of the through-spindle coolant system.

06. Electrical Maintenance

After the holiday, check if the power supply voltage is within the required range (external power supply: 380V).

It is recommended to inspect the battery before the holiday; if the battery power is low, replace the battery in time to prevent data loss.

Check if all wiring is loose, broken, or waterlogged; take waterproofing and rodent-proofing measures.

If the equipment is shut down for a long time, after the above simple maintenance, run a warm-up cycle before machining.

Warm-up Reference:

Use G01 mode:

X/Y/Z axes: F2000mm/min

A/B(C) axes: F500mm/min

Spindle: S1500-2000RPM

Run the full stroke for 1 hour with no load.

The after-sales engineers of CATO will remain at their posts and wholeheartedly provide you with timely and efficient after-sales service.

Feel free to call CATO’s after-sales hotline: 400-680-6638 for consultation. We will handle your inquiries as soon as possible.

CATO always provides 7x24-hour sunshine service. We sincerely thank you for your trust and support!

▷Email: marketing@catocnc.cn

▷Phone: 0769-38825288

▷Website: https:/https://www.catocnc.com/

Key words:

Previous Page

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638