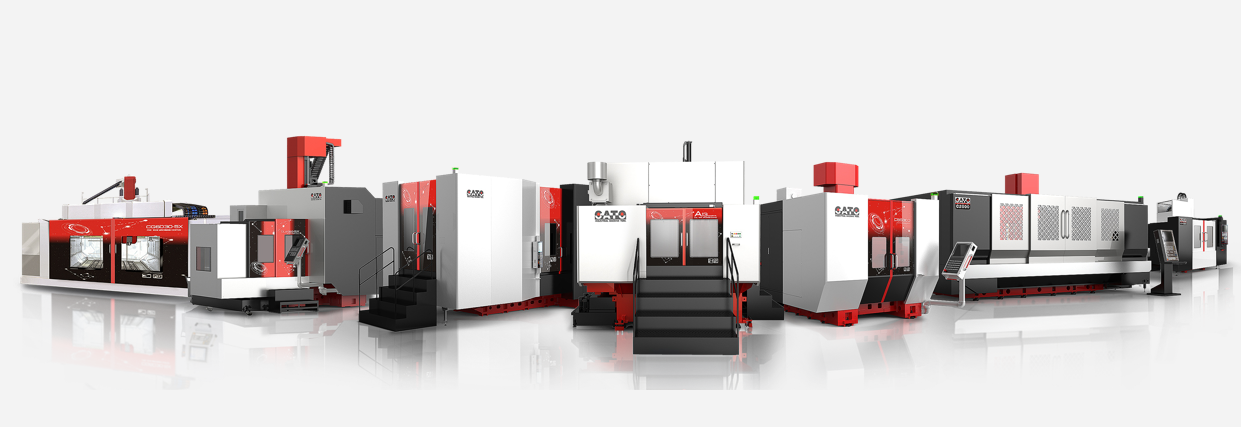

CATO CT1000 Drilling, Milling and Tapping Center: Empowering the Upgrade of Automotive and 3C Industries with High-Speed and High-Precision Technology

Release time:

2025-09-29

Author:

CATO

Source:

Internet

CATO has launched the CT1000 high-speed precision drilling, milling and tapping center, equipped with the independently developed CATO C80 Plus system. It supports 16-axis control and multiple data transmission methods, with a program execution speed of 500 blocks per second, and features both a high-rigidity structure and hollow screw cooling technology. Its self-developed BT30 electric spindle has a maximum speed of 12,000 rpm, and the 21-tool magazine achieves tool changes in just 1.2-1.4 seconds, making it suitable for precision machining in the automotive, 3C, and military industries. Benefiting from the current favorable policies for industrial machine tools, this equipment enhances the competitiveness of domestic high-end equipment and provides support for the upgrading of the manufacturing industry.

In the wave of transformation and upgrading in the manufacturing industry, a drilling, milling and tapping center that integrates high speed, high precision, and high efficiency has become a key piece of equipment for enterprises to enhance their competitiveness.

As the global manufacturing industry moves toward intelligence and high-endization, industrial machine tools—hailed as the "crown jewel" of manufacturing—have a technical level directly linked to a country’s high-end equipment manufacturing capabilities. As an outstanding representative of domestic high-end equipment manufacturers, CATO (Guangdong) Co., Ltd. has launched the CT1000 High-Speed Precision Tapping Center. Leveraging its excellent technical performance and innovative design concept, this center is driving production process innovations and efficiency improvements in the automotive manufacturing, 3C electronics, and military industries.

01 Technological Innovation: Independent Control System and High-Speed, High-Precision Performance

The CATO CT1000 High Speed High Precision Tapping Center represents the advanced technical level of China’s current CNC machine tools. The equipment adopts the independently developed CATO C80 Plus System by CATO, a self-branded control system with the feature of open internal function expansion.

This system supports the Windows operating environment, boasts high-speed and high-precision control capabilities, can handle up to 16-axis control, and comes with a standard 256MB hard disk for file storage. It offers multiple data transmission methods, including PC card, mobile hard disk, USB flash drive data backup, and Ethernet program input, enabling efficient operations of "one-time programming, batch retransmission".

The technical highlight of the CT1000 lies in its program execution speed of 500 blocks per second. Combined with dual-pitch, feedforward compensation, and optical scale dual-loop control technologies, it achieves high-speed and high-precision machining results. The system inspection screens include I/O/C/S inspection screens, real-time Ladder display, and automatic component searching function.

The PLC can send Chinese and English alarm messages, allowing operators to quickly check various machine tool faults and troubleshoot in a timely manner, greatly simplifying the operation process.

02 Structural Design: High-Rigidity Machine Body and Precision Transmission System

The CT1000 adopts a high-rigidity structural design. Its trapezoidal cross-section enhances torsional strength, while the large guideway span and low center of gravity ensure machining stability and high precision. The herringbone design and large-span mounting support surface significantly improve stability and enhance bending and torsional strength.

The X, Y, and Z axes all use linear roller guides, which feature low friction and high rigidity. The equipment adopts hollow lead screw cooling technology to ensure the thermal balance of the machine tool during high-speed operation and maintain stable precision.

The high-rigidity roller guides meet the requirements of high-rigidity machining and high-precision machining. The application of high-precision linear scales and circular scales further ensures the consistency of machining precision. These design features enable the CT1000 to maintain excellent stability and precision during high-speed machining.

03 Core Components: Independently Developed Spindle and Rapid Tool Change System

The spindle system of the CT1000 is independently developed and manufactured by CATO. It uses a BT30 built-in electric spindle with a maximum speed of up to 12,000 rpm. Forced cooling is applied to cool the motor and front/rear bearings, ensuring stable precision during high-speed and long-duration machining.

CATO has mastered core technologies and possesses the capabilities of spindle design, manufacturing, and assembly. The constant temperature and humidity workshops and refined modular production model ensure that the spindle has the characteristics of high rigidity, high speed, high power, high torque, and high reliability.

The equipment is equipped with a 21-tool-position tool magazine, which supports tools with a maximum diameter of 80mm, length of 250mm, and weight of 2kg. The tool change time (tool-to-tool) is only 1.2-1.4 seconds. This efficient tool change system greatly reduces non-machining time and improves the overall utilization rate of the equipment.

04 Application Fields: Precision Machining Solutions for Multiple Industries

The CT1000 Drilling, Milling and Tapping Center demonstrates outstanding performance in multiple manufacturing fields:

Automotive Industry

In the automotive manufacturing field, the CT1000 can efficiently machine key components such as new energy battery casings, engine casings, and gearbox casings. With the rapid development of the new energy vehicle market, the demand for precision components continues to grow, and the high-precision machining capability of the CT1000 perfectly meets this demand.

3C Industry

In the 3C electronics field, the CT1000 is suitable for machining precision parts such as mobile phones, smart watches, laptops, and communication cavities. 3C products have extremely high requirements for part precision and surface quality, and the high-speed and high-precision characteristics of the CT1000 make it an ideal choice for the 3C manufacturing industry.

Military Industry

In the military manufacturing field, the CT1000 can machine complex parts such as impellers, aviation mounts, door closer housings, and rear wheel fixed seats. Military products have extremely strict requirements for material performance and machining precision, and the high-rigidity structure and high-precision control system of the CT1000 ensure the fulfillment of these requirements.

05 Industry Background: Industrial Machine Tools Embrace New Development Opportunities

Currently, China’s industrial machine tool industry is ushering in unprecedented development opportunities. According to statistics, the market size of China’s industrial machine tools has grown from 631.4 billion yuan in 2019 to 712.9 billion yuan in 2024. The output of metal cutting machine tools and metal forming machine tools reached 695,000 units and 160,000 units respectively, with growth rates of 13.38% and 5.96% respectively.

In September 2025, the Standardization Administration of China and the Ministry of Industry and Information Technology issued the High-Quality Standard System Construction Plan for Industrial Machine Tools, proposing that by 2026, no less than 300 standards will be formulated or revised, no less than 5 relevant international standards will be led and formulated/revised, and the international standard conversion rate will reach 90%.

This policy will provide a clearer development direction and technical specifications for the industrial machine tool industry. Digital transformation has also become an important trend in the development of the machine tool industry. In September 2025, Shandong Province held the "Machine Tool Industry Digital Transformation Training Course and 'Hundred Cities, Thousand Parks Tour' Activity for Industrial Internet Integration into Parks", promoting the digital transformation process of industrial enterprises.

06 CATO: A Technologically Leading High-End Equipment Manufacturer

As a leading domestic high-end equipment manufacturer, CATO has always been committed to technological innovation and product R&D. The company has complete capabilities in spindle design, manufacturing, and assembly, realizing independent and controllable core technologies.

CATO adopts constant temperature and humidity workshops and a refined modular production model to ensure the stability and reliability of its products. Its products feature high rigidity, high speed, high power, high torque, and high reliability, and have significant competitiveness in both domestic and international markets.

Facing the transformation and upgrading of the global manufacturing industry, CATO continues to increase R&D investment and launch a series of high-end CNC equipment that meets market demands, providing solid support for the transformation and upgrading of China’s manufacturing industry.

As China’s manufacturing industry continues to move toward high-quality development, the technological breakthrough of the CATO CT1000 High Speed High Precision Tapping Center not only enhances the international competitiveness of China’s high-end equipment manufacturing industry but also provides strong technical support for the automotive manufacturing, 3C electronics, and military industries.

The rise of domestic high-end equipment is changing the long-standing pattern of relying on imports, providing solid guarantees for the independent and controllable development of China’s manufacturing industry.

▷ Email: hujuzhen@catocnc.com

▷ Phone: +86 138-2920-2050

▷ For details, visit: https://www.catocnc.com/products_details/28.html

Key words:

Previous Page

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638