CATO's 5-Axis Gantry Machining Center Breaks Technological Barriers, Empowering the Upgrade of Aerospace and Automotive Mold Industries

Release time:

2025-09-15

Author:

Source:

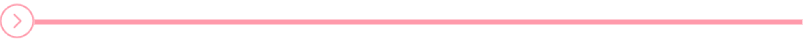

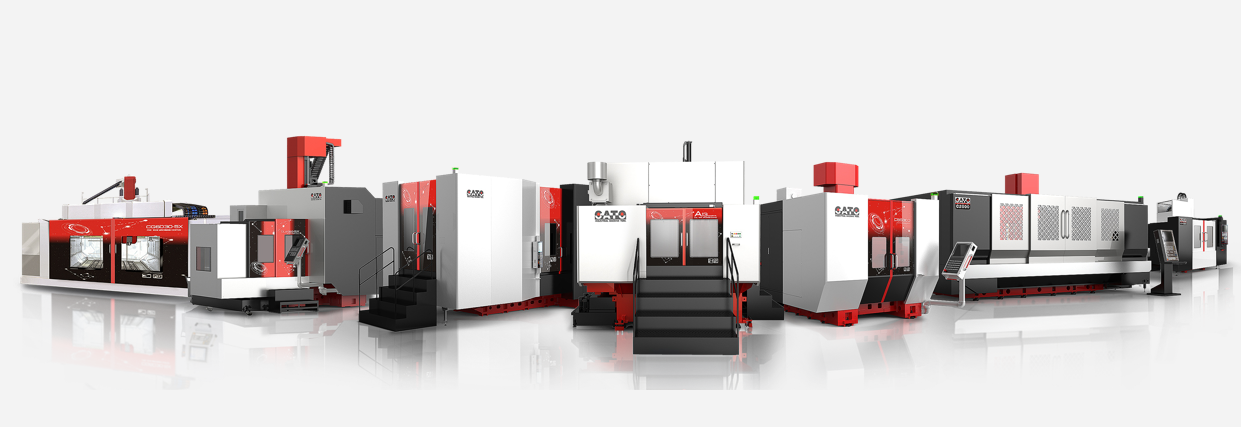

CATO has launched the GE6030L Overhead Gantry-Type 5-Axis Gantry Machining Center, which takes linear motor drive, the self-developed C80 Plus system and HSK-A63 built-in electric spindle as its core. Combined with the box-in-box symmetric beam and integrated column structures, it ensures high precision and stability. This machining center can process large aerospace structural parts and automotive stamping dies, and adapts to the lightweight needs of new energy vehicles. Currently, the global precision blanking die market is growing steadily, with broad space for domestic high-end equipment replacement. This equipment empowers the upgrading of these two industries and promotes the independent and controllable development of the manufacturing industry.

Against the backdrop of the global manufacturing industry accelerating its transformation toward high precision and high efficiency, 5-axis linkage CNC machine tools have become core equipment in the aerospace and automotive manufacturing sectors. The newly launched GE Overhead Gantry-Type 5-Axis Gantry Machining Center GE6030L by CATO (Guangdong) Co., Ltd. is bringing innovations in production processes and efficiency improvements to these two industries with its breakthrough technical performance and innovative design concept.

I Technological Innovation: Linear Motor Drive and Self-Developed Core System

CATO's GE6030L Overhead Gantry-Type 5-Axis Gantry Machining Center represents the top technical level of China's high-end CNC machine tools currently. The equipment adopts high-performance linear motor direct drive technology, with the rapid movement speed of X/Y axes reaching up to 60 m/min. It is equipped with a high-precision grating scale feedback system (resolution: 0.01μm), ensuring ultra-high precision machining capability.

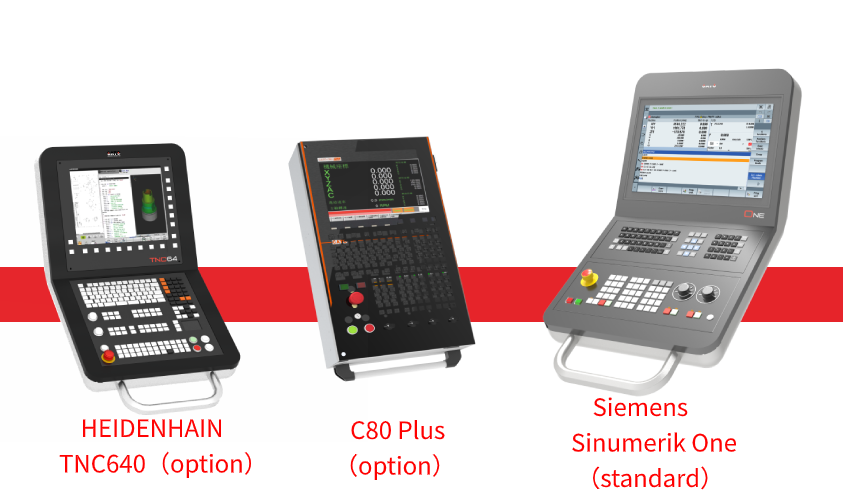

In terms of CNC systems, CATO provides multiple options, including internationally renowned systems such as Germany's Heidenhain TNC640 and Siemens, as well as the company's self-developed C80 Plus system. This self-developed system features real-time monitoring of servo motor temperature rise and load changes, adopts a Chinese operation interface and common expressions in China's manufacturing industry, significantly reducing the learning cost for operators.

The core component of the equipment—the spindle system—is also independently developed and manufactured by CATO. It adopts an HSK-A63 built-in electric spindle with a maximum speed of up to 24,000 rpm. Forced cooling is used to cool the motor and front/rear bearings, ensuring stable precision during high-speed and long-term machining. The constant temperature and humidity workshop and refined modular production mode ensure that the spindle has the characteristics of high rigidity, high speed, high power, high torque, and high reliability.

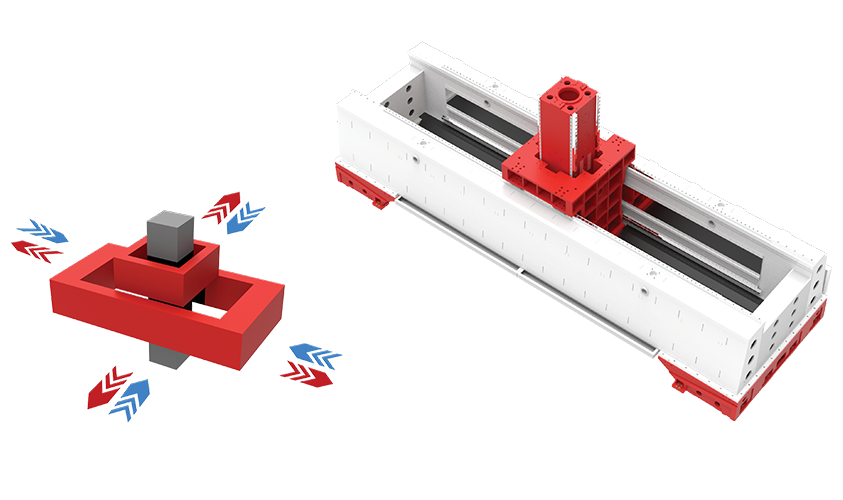

II Structural Design: Box-in-Box Symmetric Design and High-Rigidity Integrated Structure

The GE6030L adopts an innovative box-in-box symmetric beam structure design, which effectively stabilizes the spindle center and ensures high precision during machining. This design can reduce thermal deformation, enhance rigidity, make precision less affected by ambient temperature, and significantly improve the stability of the machine tool.

The column adopts an integrated high-rigidity structural design, so that the three axes are not affected by the size and weight of the workpiece in terms of machining efficiency during high-speed acceleration and deceleration movements. The overall structure is stable with good rigidity, capable of bearing large workloads and ensuring stable performance of the equipment under heavy cutting conditions.

For the transmission system, CATO adopts dual-motor electronic anti-backlash technology. Through the master-slave control function of the system, electronic tension is applied to ensure the rigidity of the transmission system, eliminate transmission backlash, and improve transmission precision. This technology solves the backlash problem in traditional transmission methods and significantly improves machining precision.

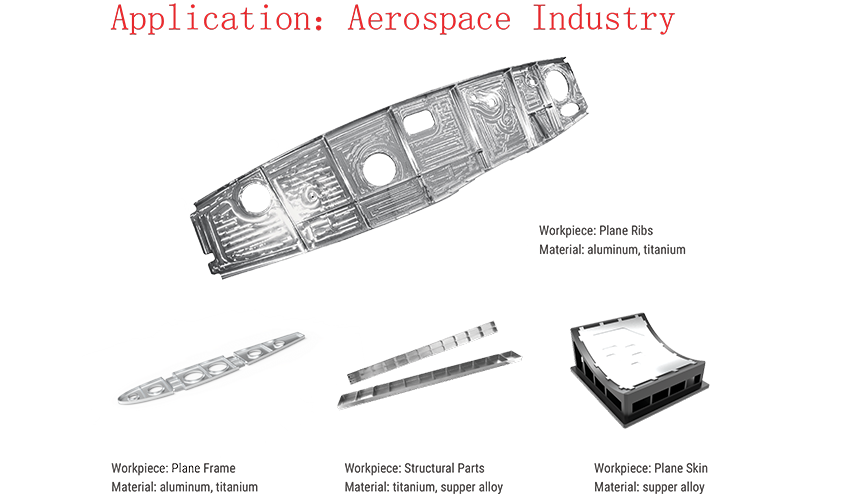

III Aerospace Application: Revolutionary Breakthrough in Large Structural Part Machining

In the aerospace field, CATO's GE6030L performs excellently. Its X/Y/Z axis travel reaches 620032001250mm, the worktable size is 6000x3000mm, and the load-bearing capacity is up to 10,000 kg, which can easily meet the machining needs of large parts such as aircraft rib plates, aircraft ribs, aircraft structural parts, and aircraft skins.

The aerospace field has extremely strict requirements for the machining of precision parts. The 5-axis linkage machining capability enables the GE6030L to achieve high-precision machining of complex curved surfaces without multiple clamping, greatly shortening the production cycle and improving machining efficiency. The linear motor direct drive technology ensures high precision and high stability when machining large aerospace structural parts, meeting the strict requirements of the aerospace industry for part quality.

The equipment is equipped with a 24-tool magazine, which supports tools with a maximum diameter of 70mm, length of 300mm, and weight of 8kg, meeting the demand for multiple tools in the machining of complex parts in the aerospace field.

IV Automotive Mold Manufacturing: A Powerful Tool for Precision Stamping Mold Machining

Automotive stamping molds are indispensable key process equipment in the automotive manufacturing process. CATO's GE6030L can efficiently machine large automotive covering molds such as roof stamping dies, hood stamping dies, and side tail stamping dies, and its material adaptation range includes various high-strength materials such as P20 mold steel.

Automotive precision stamping parts usually require high precision and consistency. The high-rigidity structure and high-precision control system of CATO's GE6030L ensure the precision requirements of mold machining. The torque motor direct drive technology achieves machining effects of no backlash, no wear, high acceleration/deceleration, low noise, and low vibration, and can maintain high-precision machining for a long time.

| Sector Classification | Application Field | Parts Manufactured with Precision Stamping Materials | Core Value |

| Key Industrial and Transportation Sectors | Automotive Components | Gearboxes, engines, seats, clutches, automotive safety belts, bearings, flanges, cam discs, various shift forks, lock plates, ratchets, brake shoes, pawl tooth plates | Supporting the performance, safety, and reliability of automobiles |

| Electrical Products | Generator rotors, electrical switches, valve plates, transformer casings, wind power disc springs, power tools, switch mechanisms, limit blocks | Ensuring the precision and stability of power equipment and electrical appliances | |

| Rail Transit | Transmission gears, air conditioning fins, shock-absorbing springs, seats, exhaust flanges | Meeting the high requirements of rail transit equipment for precision and durability | |

| General Machinery and High-End Manufacturing Sectors | General Machinery | Textile machinery parts, grinding machine parts, planer parts, sprocket transmission parts, valve plates, cooling system parts | Realizing precise coordination and efficient operation of mechanical structures |

| Precision Instruments | Pointers, gear transmission mechanisms, springs, clockwork springs | Ensuring the accuracy of instruments (adapting to the extremely high requirements of precision instruments for part precision) | |

| Aerospace | Precision gears, electrical components, hydraulic actuators, launch system parts | Supporting the strict requirements of aerospace equipment for "performance, precision, and reliability" |

With the rapid development of the new energy vehicle market, the demand for automotive lightweighting is increasing, and the application proportion of lightweight materials such as aluminum alloys in automotive manufacturing is rising year by year. This puts higher requirements on the stamping process and also requires higher-precision molds for support. The high-speed spindle and 5-axis linkage capability of the GE6030L enable it to efficiently machine molds for lightweight materials, meeting the special needs of new energy vehicle manufacturing.

V Market Prospects: Broad Space for Domestic High-End Equipment Replacement

Currently, the global precision blanking die market is growing steadily. Industry reports indicate that the global precision blanking die market sales volume is expected to reach 4306 million US dollars in 2024 and 6299 million US dollars by 2031, with a compound annual growth rate (CAGR) of 5.80%.

In the Chinese market, as the pace of manufacturing transformation and upgrading accelerates, the demand for high-end CNC machine tools continues to grow. Especially in fields such as aerospace and new energy vehicles, the demand for high-precision and high-efficiency machining equipment is strong. National policies supporting the high-end equipment manufacturing industry also provide a strong guarantee for the development of the industry.

As a domestic machine tool manufacturer mastering core technologies, CATO's GE Overhead Gantry-Type 5-Axis Gantry Machining Center has reached the international advanced level in performance. At the same time, it has advantages in localized services and costs, and has significant competitiveness in replacing imported products in the domestic market. The company has complete spindle design, manufacturing, and assembly capabilities, realizing independent control of core technologies and providing a solid guarantee for the transformation and upgrading of China's manufacturing industry.

The technological breakthrough of CATO's GE6030L Overhead Gantry-Type 5-Axis Gantry Machining Center not only enhances the international competitiveness of China's high-end equipment manufacturing industry but also provides strong technical support for the aerospace and automotive mold industries. As China's manufacturing industry continues to move toward high-quality development, such high-end CNC equipment will play an increasingly important role in the industrial upgrading process.

The rise of domestic high-end equipment is changing the long-standing pattern of relying on imports and providing a solid guarantee for the independent and controllable development of China's manufacturing industry. In the future, CATO will continue to deepen technological innovation and provide higher-quality high-end equipment and solutions for global manufacturing customers.

Key words:

Previous Page

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638