CATO A30LIIIS 5-Axis Horizontal Swiveling Machining Center: Injecting Precision Power into New Energy Vehicle Manufacturing

Release time:

2025-09-04

Author:

CATO

Source:

Internet

【CATO Launches the Heavyweight A30LIIIS 5-Axis Horizontal Swiveling Machining Center】Tailor-made for the high-precision machining of new energy vehicle (NEV) components, it adopts linear motor and torque motor direct drive technologies. Boasting a rapid traverse speed of 120 m/min and permanent high precision, this machining center solves the machining challenges of integrated die-cast aluminum structural parts, empowering the industry to achieve efficient production.

Amid the rapid development of the new energy vehicle industry, technologies such as integrated die-casting and lightweight structures have gradually become industry standards, placing higher demands on precision machining equipment. The independently developed A30LIIIS 5-Axis Horizontal Swiveling Machining Center by CATO is emerging as a crucial force in the NEV component manufacturing sector, thanks to its exceptional precision control, high-efficiency machining capabilities, and stable performance.

01 Industry Background: NEV Sector Drives a Surge in Demand for Precision Machining

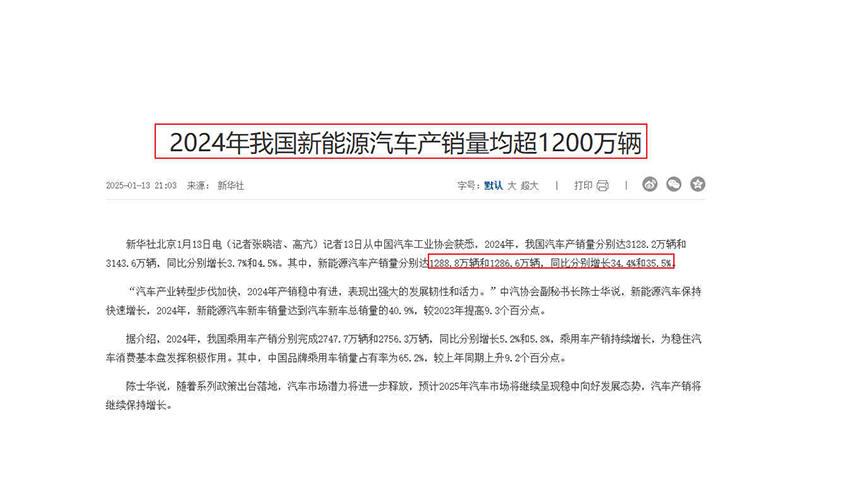

With the growing global emphasis on green mobility, the NEV market is undergoing an unprecedented transformation. The projected NEV production in 2024 reached 12.888 million units, representing a year-on-year increase of 34.4%. In this large and fast-growing market, lightweight and integrated die-cast structures have become key technologies for enhancing vehicle range and safety performance.

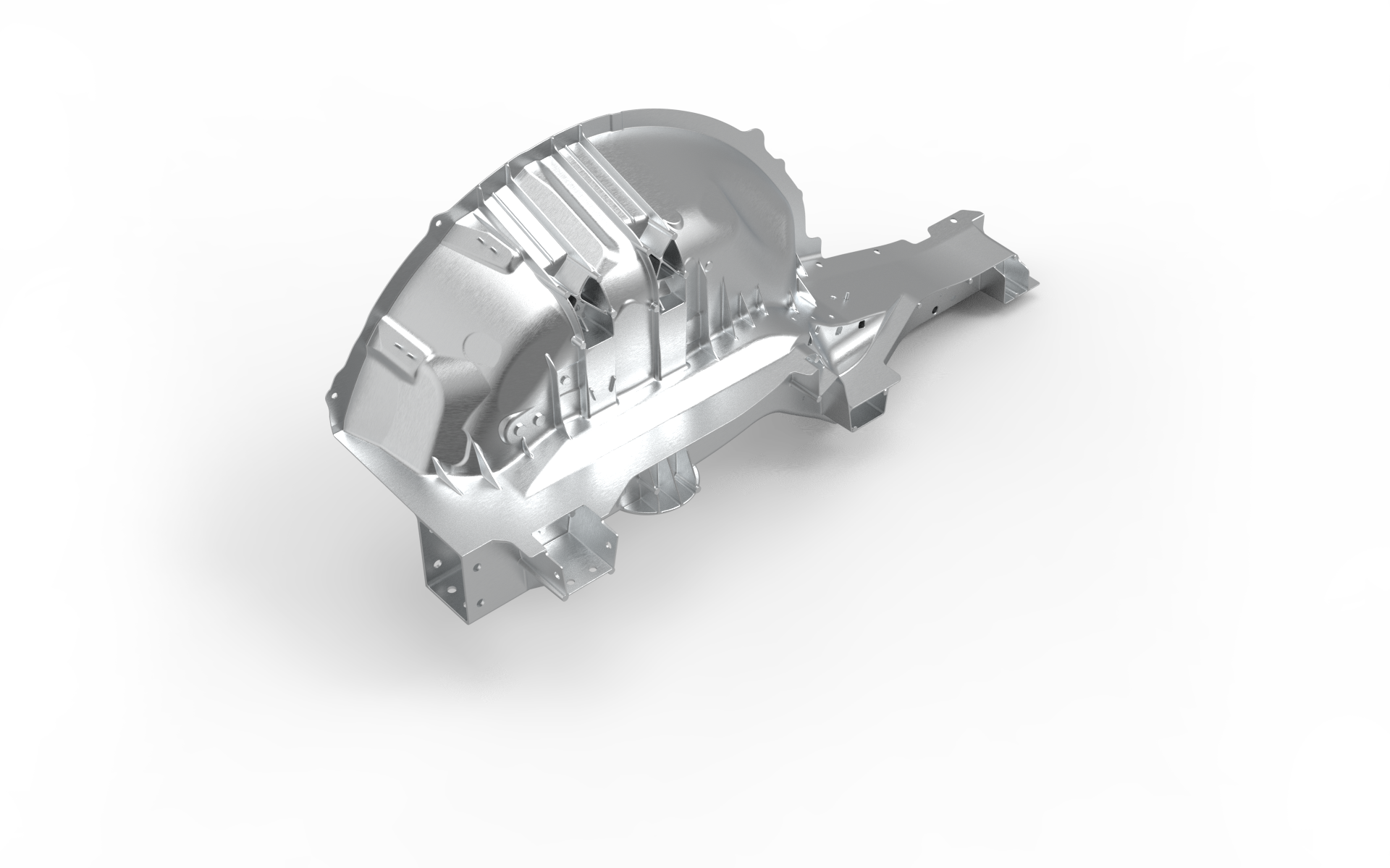

Large structural components of NEVs, such as motor housings, battery cases, and front/rear vehicle bodies, are mostly made of die-cast aluminum alloy. These parts not only have large dimensions but also require extremely high machining precision—indicators like cylindricity, coaxiality, and positional accuracy are directly related to the overall vehicle performance.

02 Technological Innovation: The Precision Machining Approach of CATO A30LIIIS

Targeting industry needs, CATO A30LIIIS 5-Axis Horizontal Swiveling Machining Center has achieved breakthroughs in a number of core technologies.

Box-in-Box Symmetrical Beam Structure

This structure effectively stabilizes the spindle center, ensuring high precision during machining. It reduces thermal deformation, maintains the stability of the spindle center, and enhances rigidity—preventing precision from being easily affected by ambient temperature, thus significantly improving the machine tool’s accuracy and stability.

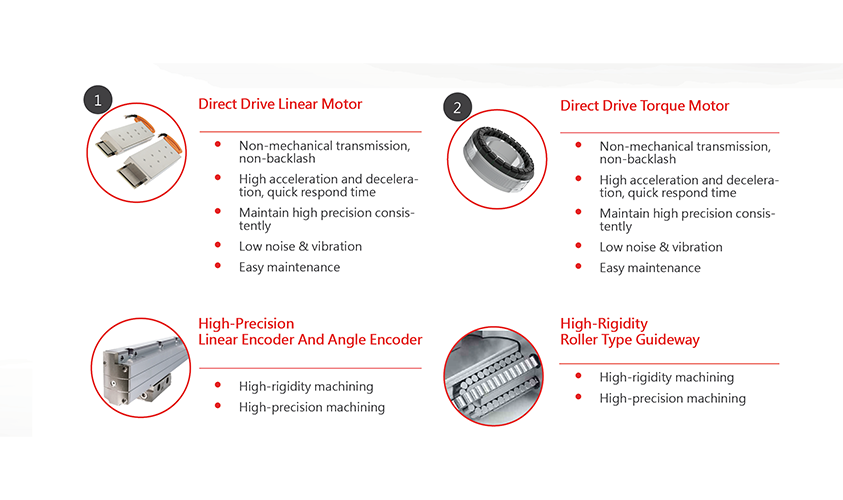

Linear Motor Direct Drive for X/Y/Z Axes

Equipped with a high-precision linear scale feedback system, the direct drive technology for X/Y/Z axes enables excellent 5-axis simultaneous machining capabilities. This caters to the aerospace industry and high-precision component manufacturing fields that pursue ultimate machining precision and efficiency.

Torque Motor Direct Drive

Another highlight of the A30LIIIS is the torque motor direct drive. The A/B axes are fitted with a self-developed trunnion table, which adopts torque motor direct drive. Featuring no mechanical transmission, this design achieves zero backlash and zero wear, maintaining permanent high precision. It operates with low noise during high acceleration/deceleration movements, and when combined with a high-precision encoder, enables accurate positioning and control throughout the machining process.

03 Application Efficiency: Enhancing Machining Quality and Efficiency of NEV Components

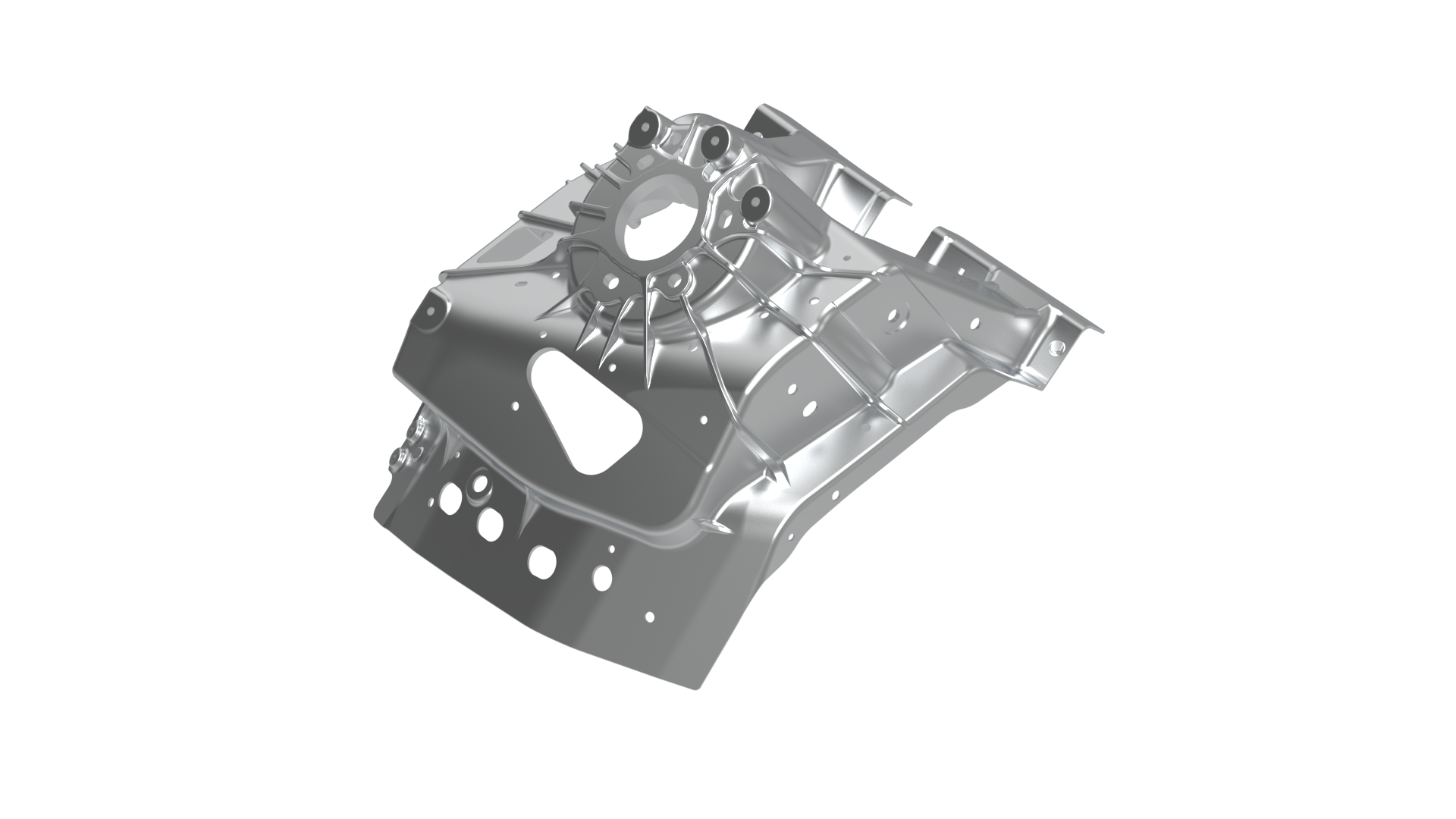

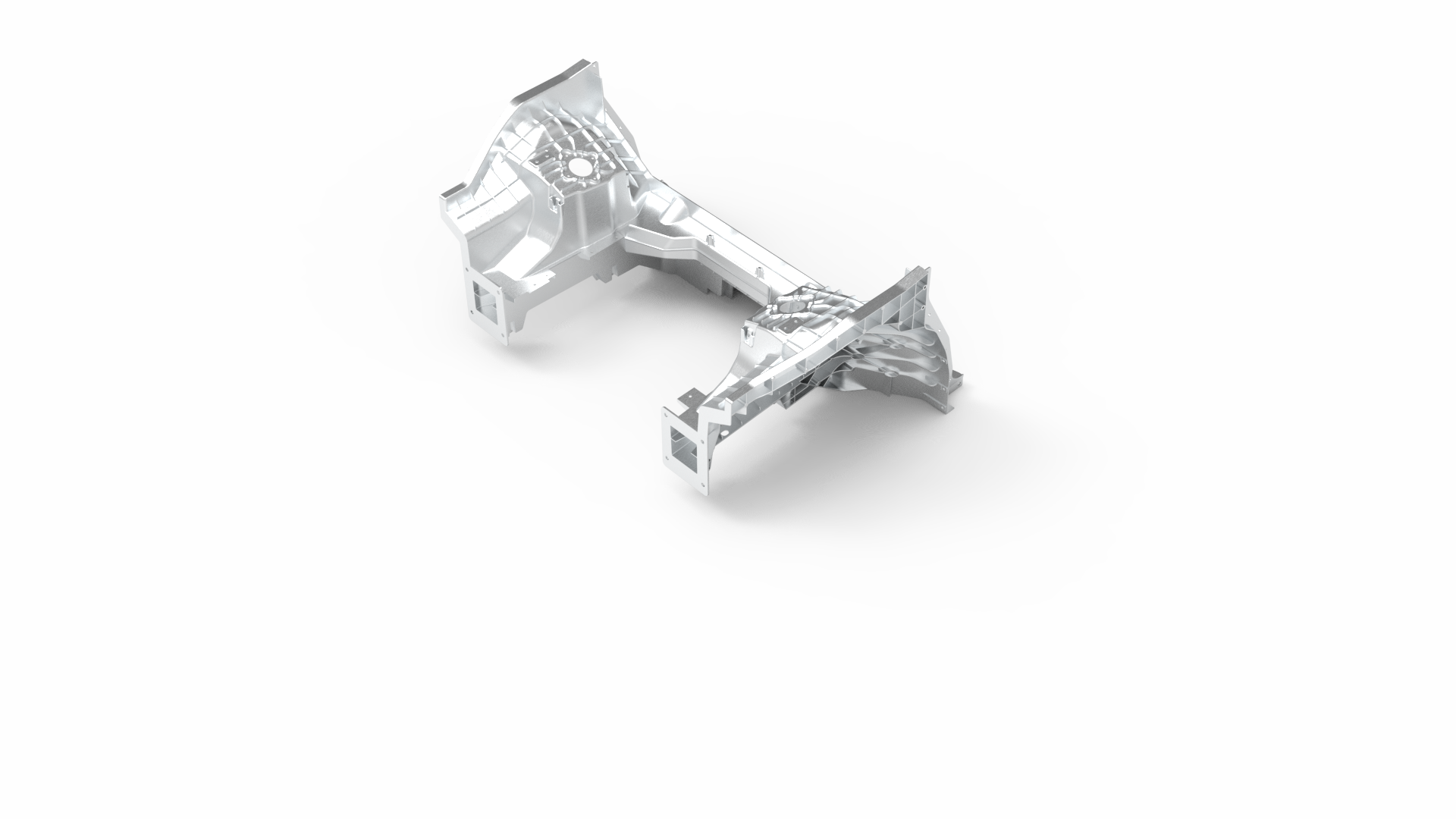

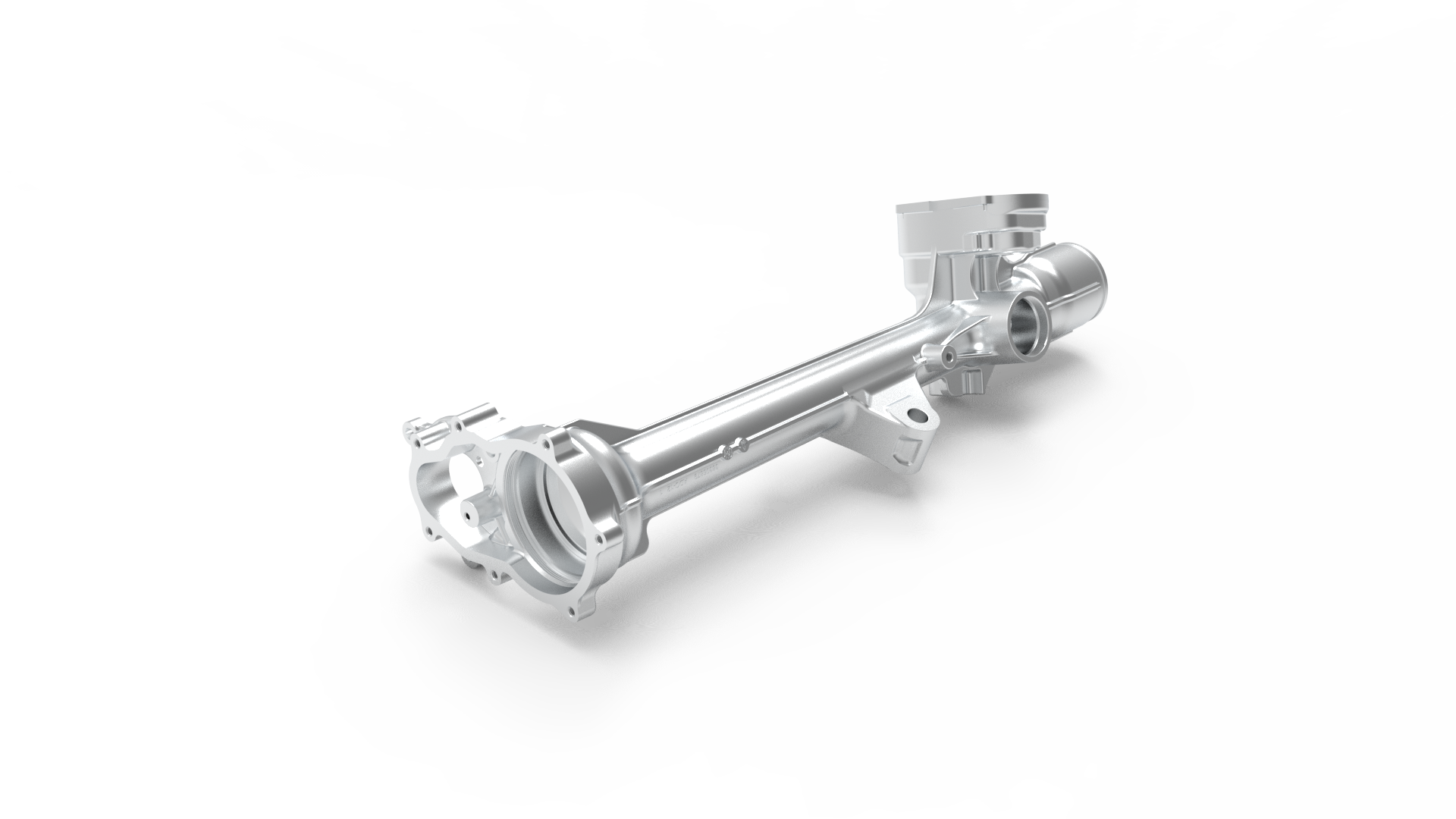

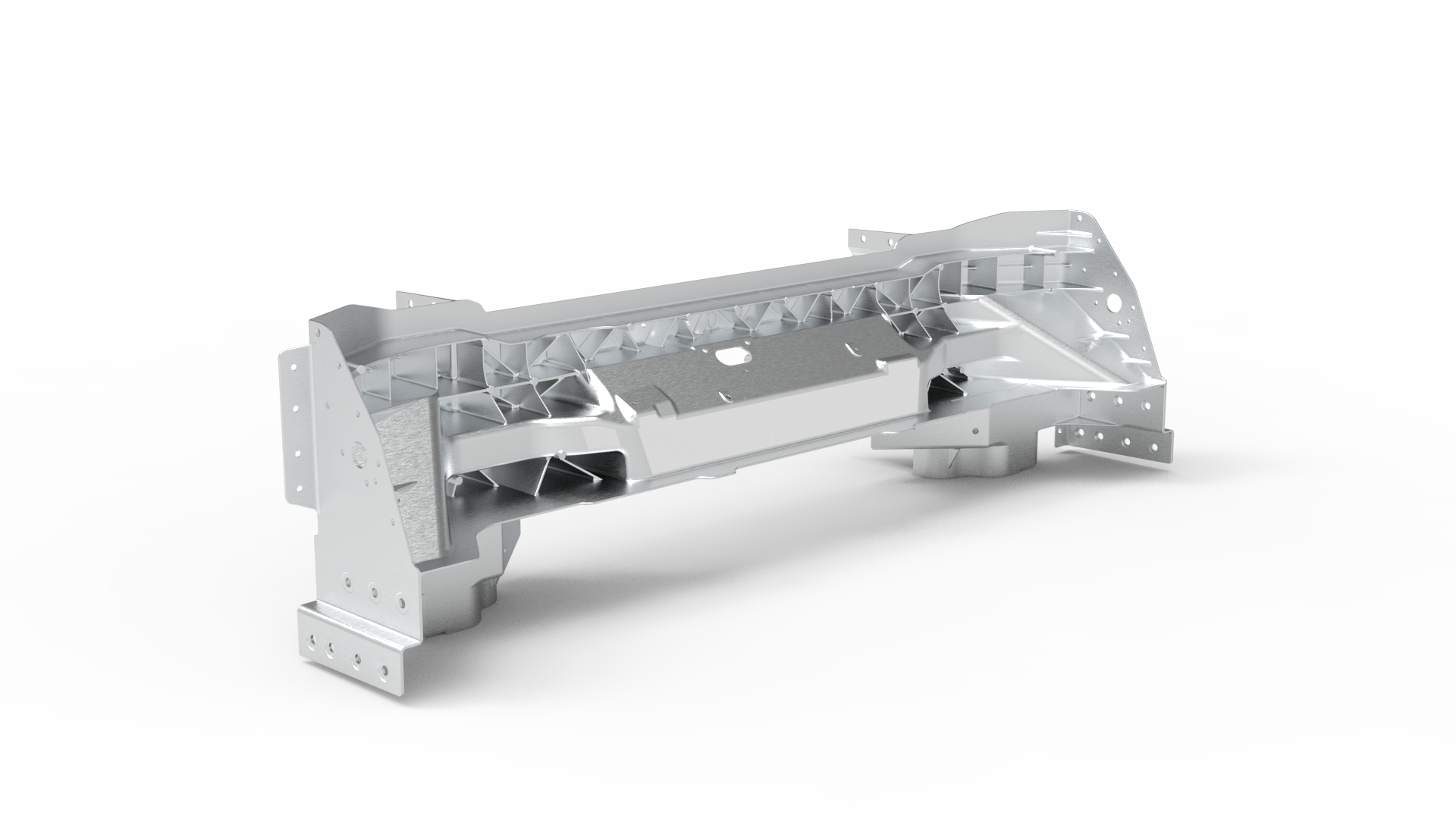

The CATO A30LIIIS delivers outstanding performance in NEV component machining. It provides an optimal solution for machining large structural parts such as rear floors, subframes, CD pillars, longitudinal beams, shock towers, and front compartments.

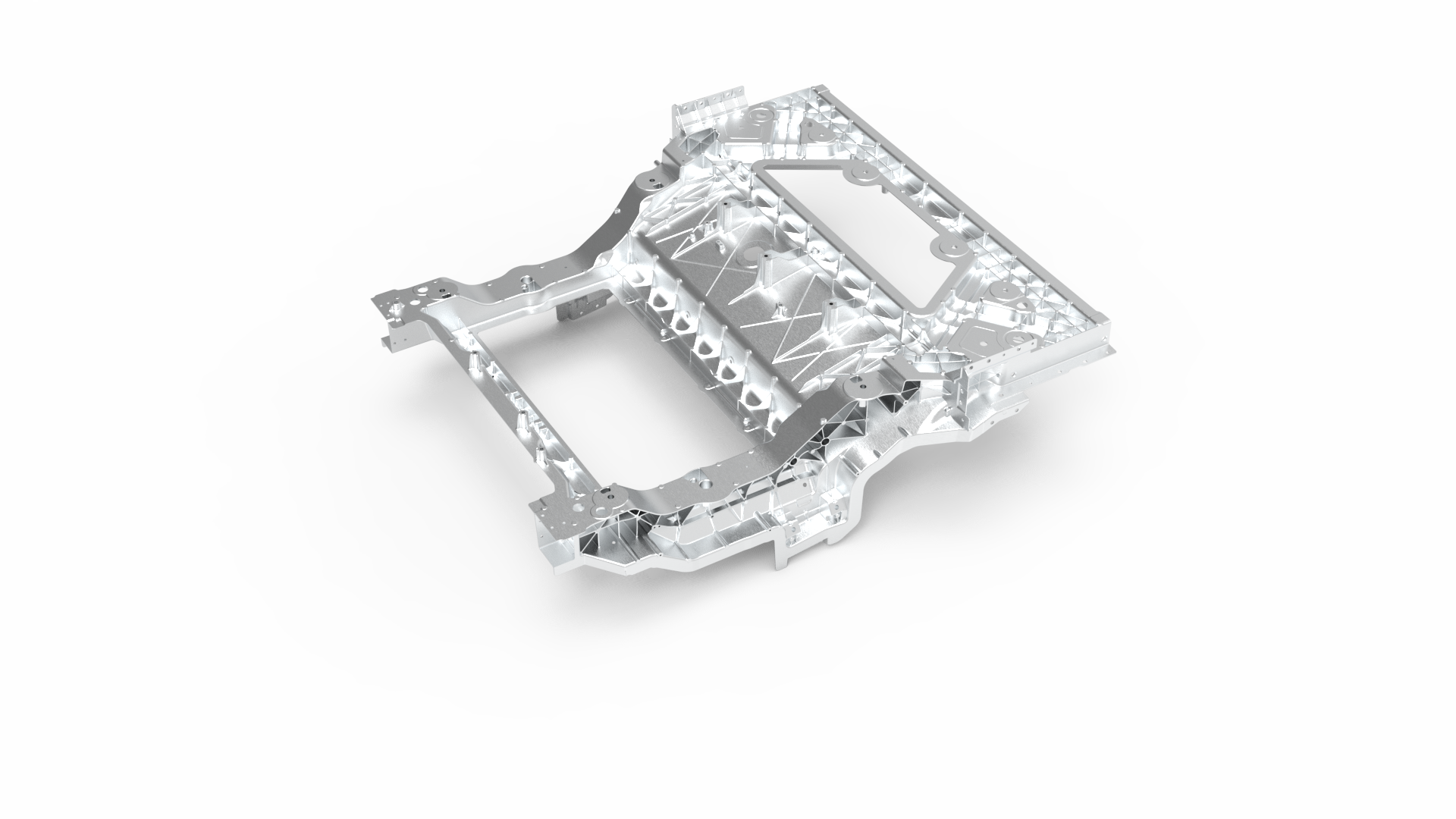

workpiece: Rear Floor

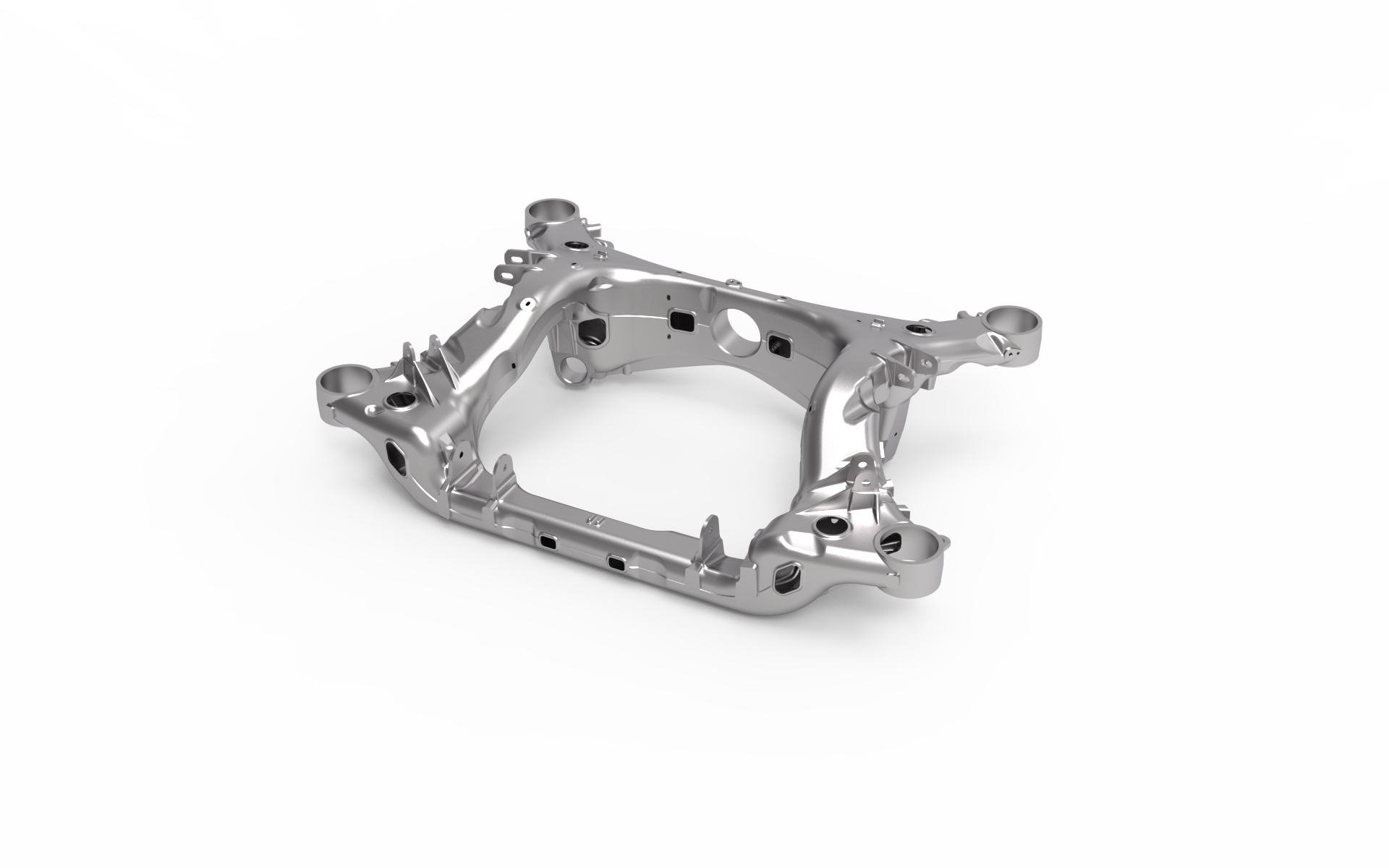

workpiece: Sub Frame

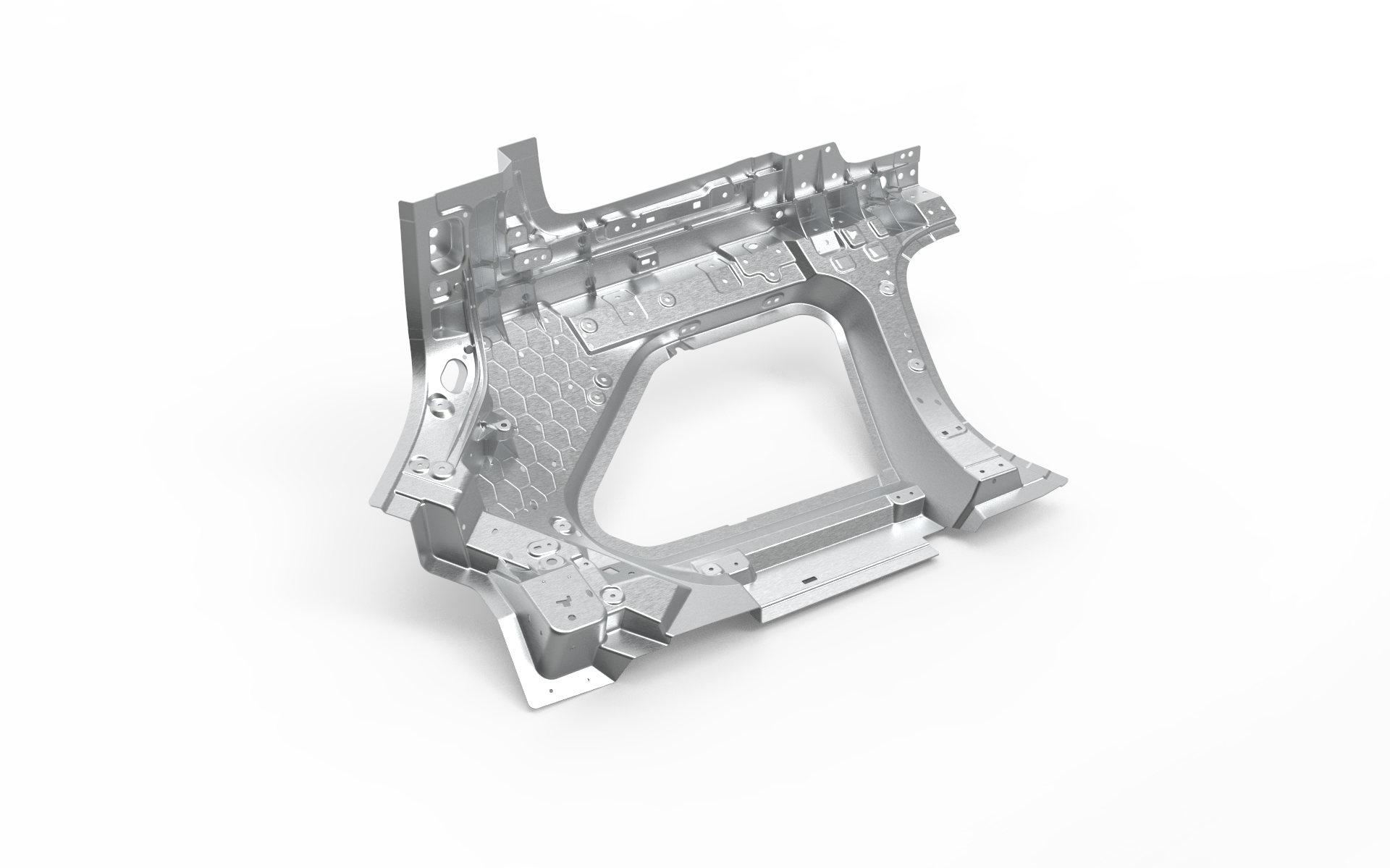

workpiece: CD Pillar

workpiece: Structural Part

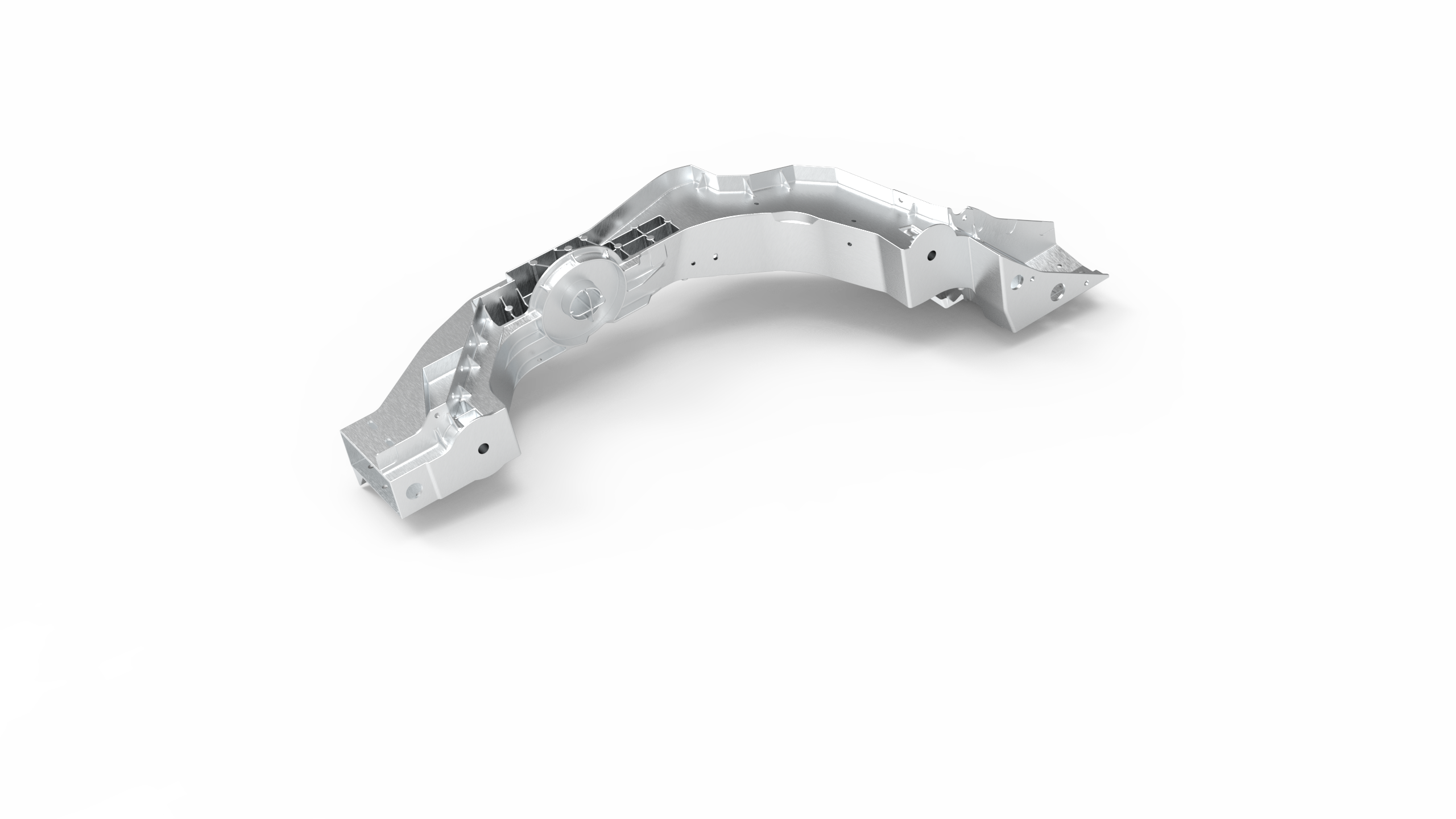

workpiece: Shock Tower

workpiece: Structural Part

workpiece: Steering Housing

workpiece: H Arm

workpiece: Torque Housing

workpiece: Motor Housing

workpiece: Structural Part

Material Compatibility

It can machine various die-cast aluminum alloys, meeting the industry’s lightweight requirements.

Efficient Structural Design

The A30LIIIS features a dual-directional triple Z-axis and a two-axis head machining design, making it a highly efficient horizontal dual-purpose universal machining center. Five independent units are distributed on both ends of the fixture, enabling simultaneous 5-axis machining on both sides—greatly boosting machining efficiency.

High-Speed Performance

The triple-spindle design and lightweight structure allow the X/Y/Z axes to achieve a rapid traverse speed of 120 m/min and an acceleration of 1G, ensuring ultra-high-efficiency simultaneous machining capabilities. This improvement in machining efficiency is crucial for the large-scale production of NEVs.

04 Market Prospects: High-End CNC Machine Tools Enter a Period of Development Opportunities

Currently, China’s CNC machine tool market is in a stage of rapid development. The market size of CNC machine tools reached 116.9 billion yuan in 2024 and is expected to grow to 151.1 billion yuan by 2029. Among them, the 5-axis machine tool segment is growing even faster—its market size is projected to reach 27 billion yuan by 2029, with a compound annual growth rate of 20.1%.

Nevertheless, the penetration rate of high-end machine tools in China was only 9.2% in 2024, far lower than the over 50% in the United States and Japan. The localization rate of 5-axis machine tools stands at 55.0%, while that of non-5-axis machine tools reaches 75.0%—leaving enormous room for high-end domestic substitution.

At the policy level, the CNC machine tool industry is also receiving strong support. The Chinese government has listed industrial machine tools (the "mother machines" of industry) as a key priority and introduced policies such as additional deductions for R&D expenses. These measures aim to promote the independent controllability and domestic substitution of high-end CNC machine tools.

With these characteristics, the A30LIIIS can meet the diverse needs of different customers, providing high-performance machining solutions for fields such as new energy vehicles, aerospace, and precision molds.

▷ Email: hujuzhen@catocnc.com

▷ Phone: +86 138-2920-2050

▷ Website: https://en.catocnc.com/

Key words:

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638