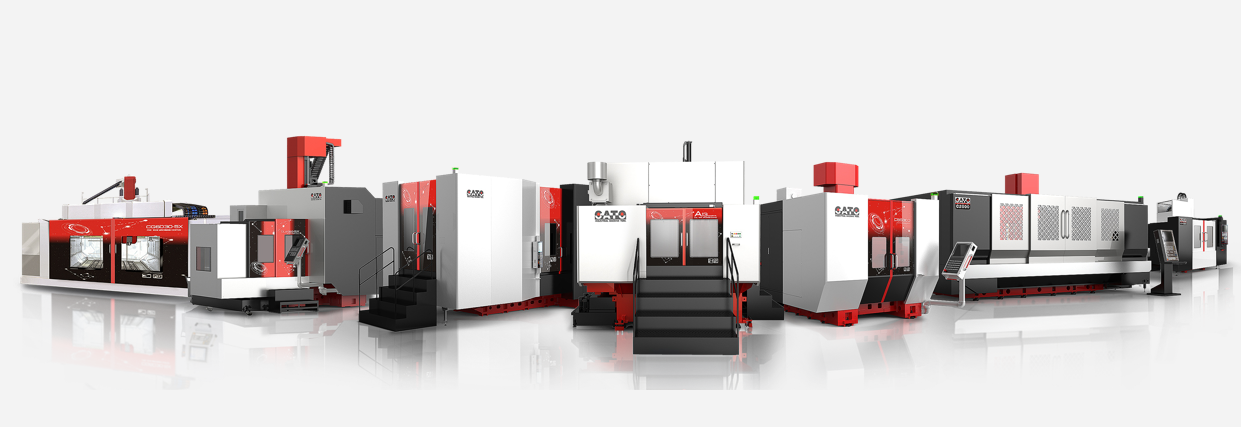

CATO CBS 1250 5-Axis Bridge-Type Machining Center: Leading a New Era of Aerospace Precision Manufacturing

Release time:

2025-09-15

Author:

CATO

Source:

Internet

CATO CBS1250 5-axis bridge-type machining center focuses on the high-end manufacturing needs of the aerospace industry, and is capable of accurately machining complex core components such as impellers, casings, and blades. It adopts a box-in-box symmetric beam structure to reduce thermal deformation and ensure stable precision. The X/Y axes are driven by linear motors and the B/C axes by torque motors directly, enabling backlash-free and high-response machining. Equipped with a self-developed built-in electric spindle and a high-precision grating scale for the Z-axis, it achieves a positioning accuracy of 0.008mm. This machining center provides efficient and high-precision manufacturing support for the "Three Aviation" industries (aviation, aerospace, and maritime), demonstrating the technological strength of domestic high-end machine tools.

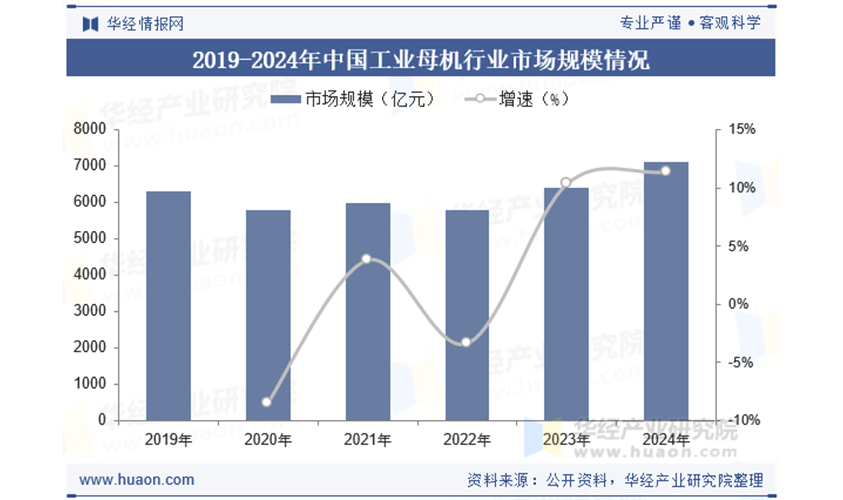

Against the backdrop of the accelerated global shift toward digitalization and intelligence in the manufacturing industry, high-end CNC machine tools, as "industrial mother machines", have become core equipment in high-tech fields such as aerospace and new energy vehicles.

Source: [Click to Jump]

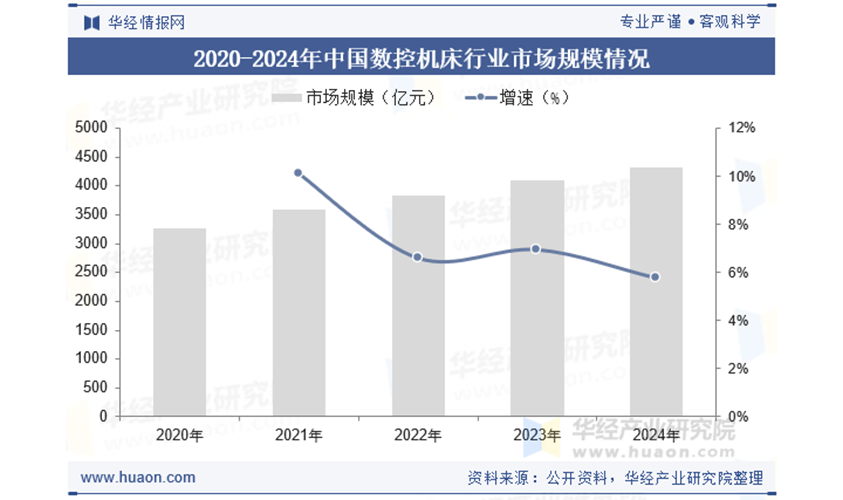

According to industry data, the market size of China's CNC machine tool industry reached 432.5 billion yuan in 2024, among which the 5-axis machine tool market is entering a period of rapid growth.

Data from the 19th China International Machine Tool Show (CIMT2025) shows that the number of domestic 5-axis machine tool exhibits soared from 50 units in the previous session to 400 units, marking the accelerated independent breakthrough of China in the field of high-end manufacturing equipment.

Ⅰ Industry Trend: Smart Manufacturing and Independent Controllability Become Dominant

Currently, the global machine tool industry is undergoing profound changes. The in-depth integration of AI technology and the machine tool industry has become the most striking focus, with numerous innovative achievements emerging continuously, driving the machine tool industry from traditional manufacturing to high-end intelligent manufacturing.

At the CIMT exhibition held in Beijing in April 2025, world-renowned machine tool and tool enterprises showcased their latest technologies and products, comprehensively demonstrating the cutting-edge trends of the machine tool industry. The exhibition theme "Integrated Innovation, Digital and Intelligent Future" accurately summarizes the development direction of the industry.

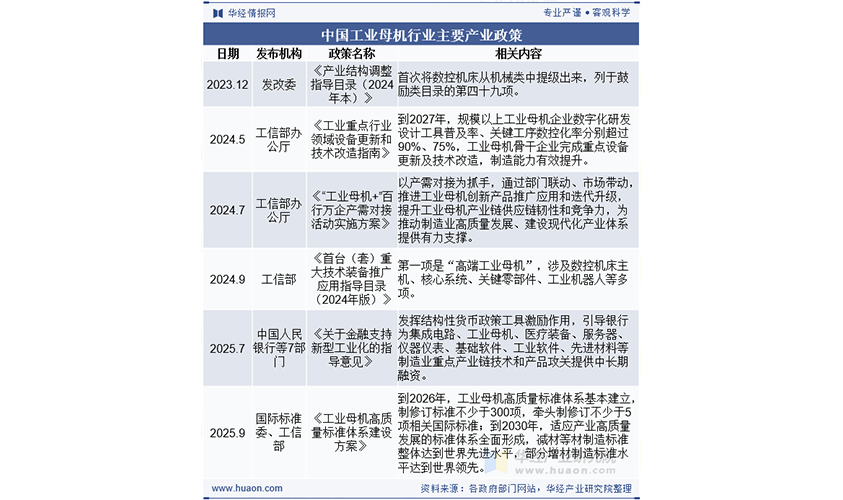

Policies are also strongly supporting the CNC machine tool industry. The High-Quality Standard System Construction Plan for Industrial Mother Machines clearly states that by 2026, a high-quality standard system for industrial mother machines will be basically established, with no less than 300 standards formulated or revised.

Source: [Click to Jump]

With the surge in demand for machining complex and precision parts in high-end manufacturing industries such as aerospace, automotive, and energy, the market is forcing enterprises to accelerate their transformation toward intelligence and high-endization.

Ⅱ Technological Breakthroughs: Innovative Design of CATO CBS 1250 5-Axis Bridge-Type Machining Center

The independently developed CBS 1250 5-axis bridge-type machining center by CATO integrates a number of industry-leading technologies and is designed for high-demand machining tasks in the aerospace, high-precision parts, and medical fields.

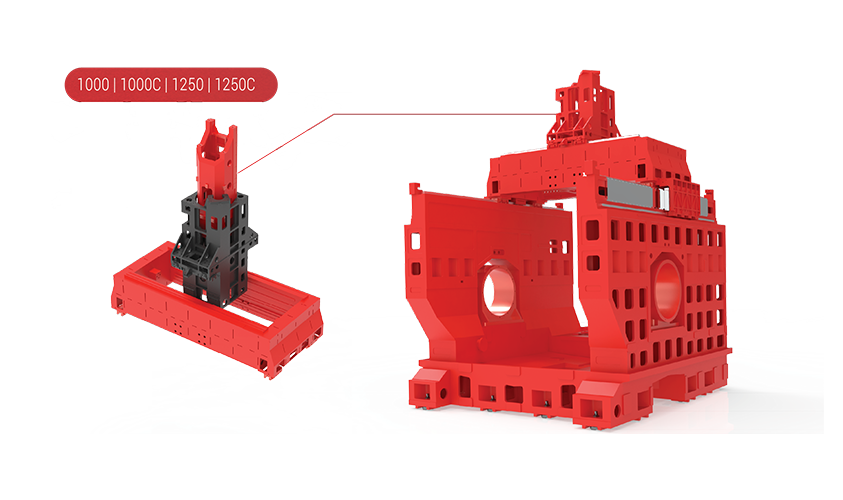

The box-in-box symmetric structure design effectively stabilizes the spindle center and ensures high precision during machining. This design reduces thermal deformation, maintains the stability of the spindle center, enhances rigidity, makes precision less affected by ambient temperature, and significantly improves the accuracy and stability of the machine tool.

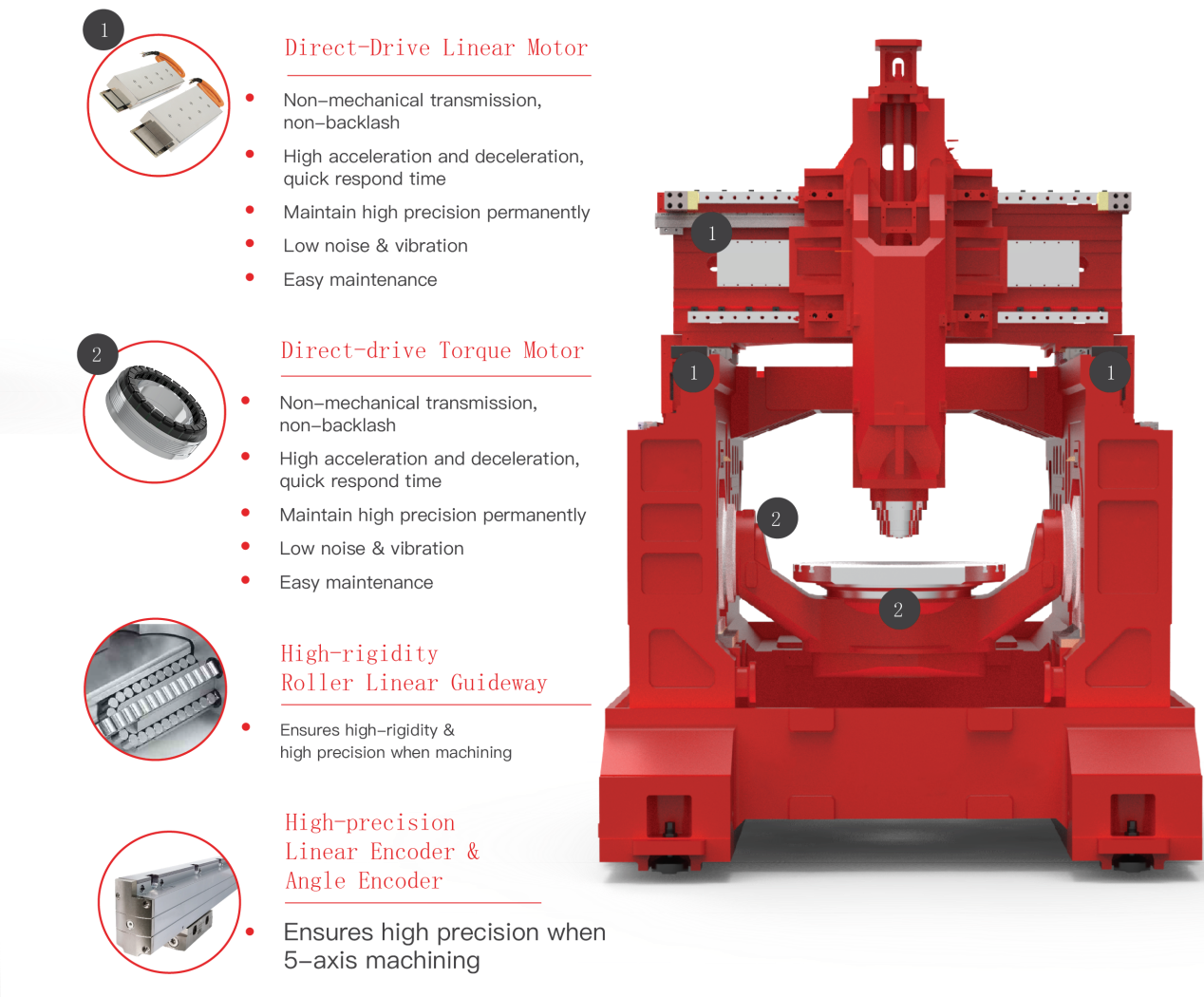

The X/Y axes adopt high-performance linear motor direct drive technology, combined with a high-precision grating scale feedback system, realizing excellent 5-axis simultaneous machining capabilities. The linear motor direct drive technology has no mechanical transmission and no backlash, and can maintain permanent high precision.

The independently developed A/C axis cradle adopts torque motor direct drive, featuring no mechanical transmission. It achieves no backlash/no wear, can maintain high precision, and operates with low noise during high acceleration/deceleration movements. Combined with a high-precision encoder, it realizes precise positioning and control during the machining process.

Ⅲ Core Parameters: Specifications Designed for High-Performance Machining

The CATO CBS 1250 5-axis bridge-type machining center is equipped with a series of impressive technical parameters:

● Worktable size: Ø1,250 mm; Load capacity: 2,500 kg (CBS1250), 1,000 kg (CBS1250C)

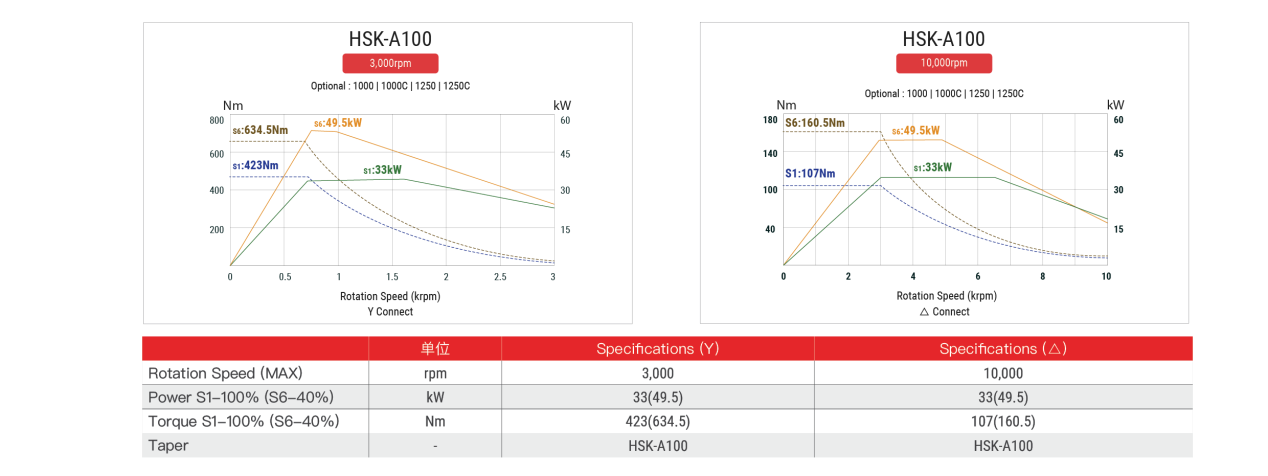

● Standard spindle: A100, maximum speed: 10,000 rpm

● XYZ axis travel: 1,250 x 1,350 x 1,000 mm

● X/Y/Z axis rapid traverse speed: up to 60 m/min

● A-axis rotation angle: ±110°, C-axis rotation angle: ±360°

● Tool magazine (ATC) capacity: up to 60 tools; Tool change time (tool-to-tool): only 8 seconds

These parameters enable the CBS 1250 to meet the efficient machining needs of various complex components in the aerospace field.

Ⅳ Application Fields: Focus on High-Precision Manufacturing Tasks

The CATO CBS 1250 5-axis bridge-type machining center focuses on high-demand machining application fields:

Aerospace Field: Precision machining of complex-shaped workpieces such as impellers, closed blisks, integral blisks, fan blisks, fan components, aero-engine casings, casing parts, spiral parts, and turbine parts.

High-Precision 5-Axis Parts: Precision parts requiring extremely high precision and surface quality, suitable for mold, precision instrument and other fields.

Medical Field: Medical equipment and implants with strict requirements on machining precision and surface quality.

Ⅴ Independent Innovation: Mastering Core Technologies

CATO has achieved comprehensive independent innovation in the field of core components:

Independently developed built-in electric spindles, adopting HSK-E40/HSK-A63/HSK-A100 built-in electric spindles. Within the spindle rotation range, runout and vibration are eliminated, achieving stable precision during long-term high-speed machining.

The spindle uses forced cooling to cool the motor and front/rear bearings, ensuring thermal stability during long-term high-speed operation.

CATO masters core technologies and possesses the capabilities of spindle design, manufacturing, and assembly. In a constant temperature and humidity workshop, it adopts a fine modular production mode, and the produced spindles feature high rigidity, high speed, high power, large torque, and high reliability.

Ⅵ Diverse Control Systems: Meeting Different Customer Needs

The CATO CBS 1250 5-axis bridge-type machining center offers a variety of control system options to adapt to the preferences and needs of different users:

This flexibility allows the equipment to be better integrated into the user's existing production environment and workflow.

Ⅶ Market Prospects: Domestic High-End Machine Tools Embrace Development Opportunities

Currently, the long-term trade deficit in China's overall machine tool industry is gradually narrowing, indicating that domestic machine tools are steadily moving toward independent controllability and localized development. The value of exported machine tool products continues to increase, and domestic machine tools are constantly advancing toward intelligence and high-endization.

Source: [Click to Jump]

In the field of high-end CNC machine tools, there is significant room for localized development. As a leading domestic machine tool manufacturer, CATO is helping China's manufacturing industry leap from a "big manufacturing country" to a "powerful intelligent manufacturing country" through continuous technological innovation and product upgrading.

With the surge in demand for machining complex parts in fields such as aerospace and new energy vehicles, domestic 5-axis machine tools, relying on advantages such as high cost performance, customized services, and an independently controllable supply chain, are gradually breaking the monopoly of foreign products.

The CATO CBS 1250 5-axis bridge-type machining center represents the latest achievement of domestic high-end CNC machine tools. Its outstanding performance in precision, efficiency, and reliability makes it an ideal choice for customers in the aerospace, precision manufacturing, and medical fields.

As the global manufacturing industry continues to move toward intelligence and flexibility, CATO will continue to deepen technological innovation and provide solid support for the high-quality development of China's manufacturing industry.

Welcome to learn more about the CATO CBS 1250 5-axis bridge-type machining center. Our professional team is ready to provide you with customized solutions at any time.

Key words:

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638