Unlock the Future of Manufacturing with CATO at Dongguan CMES 2024!

Release time:

2025-01-18

Author:

CATO

Source:

CATO

Dive into the future of precision manufacturing at CATO's booth 3B57, Dongguan CMES exhibition, Nov 11-14.

Dear Industry Enthusiasts,

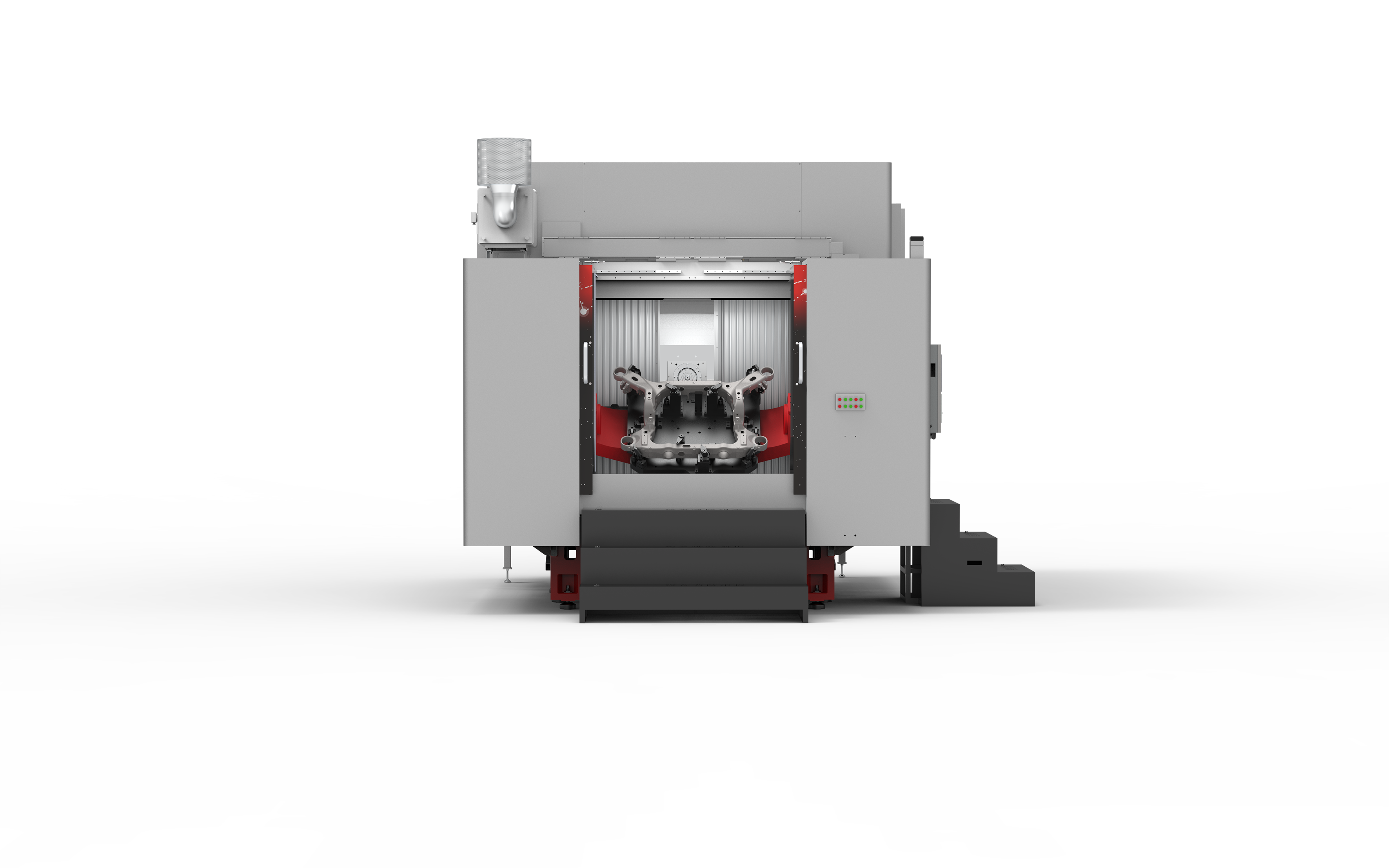

We are thrilled to invite you to the Dongguan CMES exhibition, where CATO will be showcasing its latest advancements in precision manufacturing. Our booth is designed to be a prominent and eye-catching feature, strategically highlighting our 5-axis bridge-type machining center CBS800 and 5-axis horizontal swiveling machining center A13. They are specialized in aerospace and electric vehicle industries respectively.

Why Visit Our Booth?

Experience Innovation:

Witness the future of manufacturing with our direct drive technology, enhancing the productive efficiency of machining centers.

Explore High-Tech Solutions:

Discover how our machining centers are revolutionizing the electronic vehicle and aerospace industries.

Engage with Experts:

Meet our knowledgeable staff who will provide detailed explanations and live demonstrations.

Network with Peers:

Join a community of industry leaders and innovators, all under one roof.

Date & Time: 11-14, November, 2024 | 9: 30-17: 30

Location & Booth No.: Guangdong Modern International Exhibition Center, Houjie, Dongguan | 3B57

Don't miss this opportunity to witness CATO's commitment to quality and innovation in action. We look forward to welcoming you at our booth.

Best regards,

CATO

Detail Info.

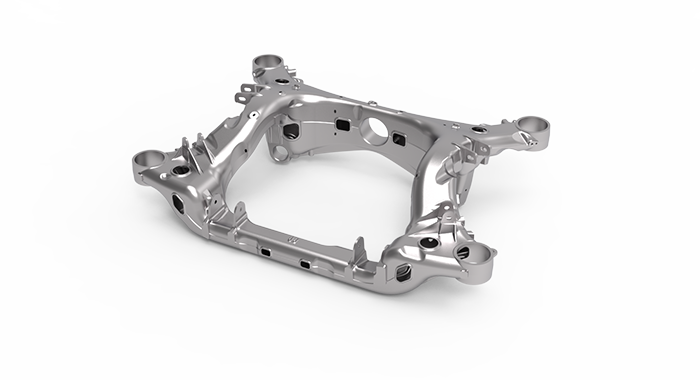

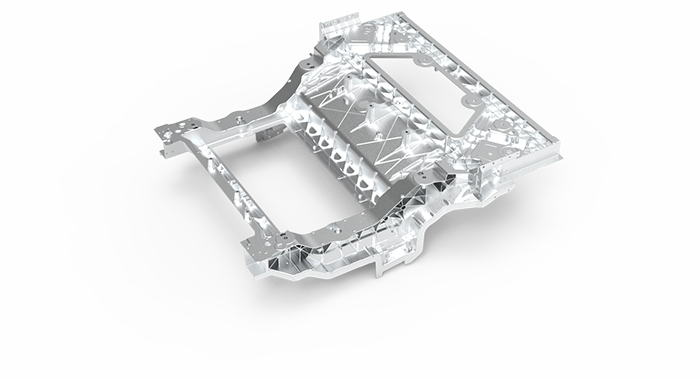

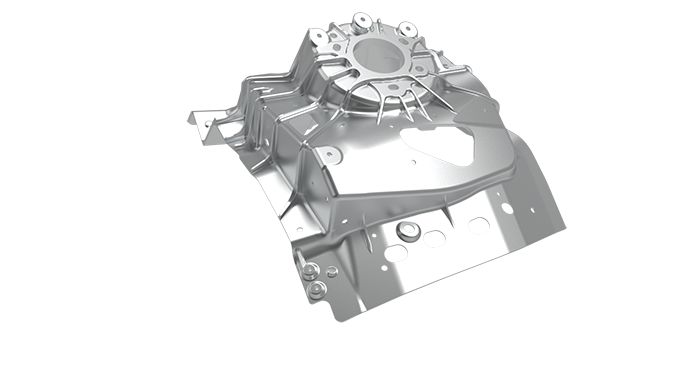

Application in E-mobility

Subframe, shock tower, H-arm, steering housing, steering knuckle etc.

Subframe

Rear floor

Shock tower

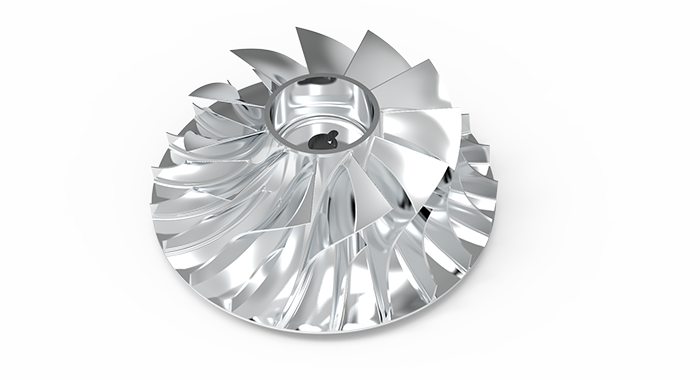

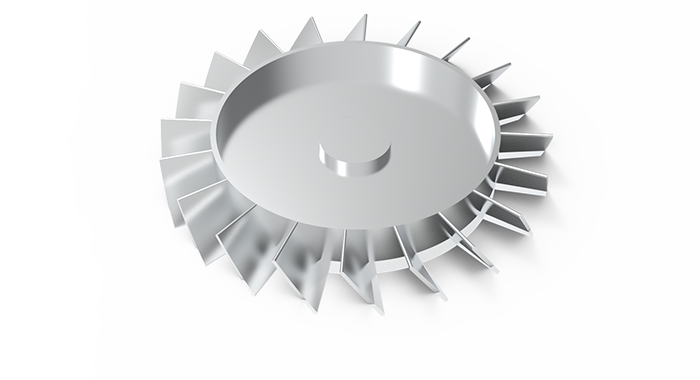

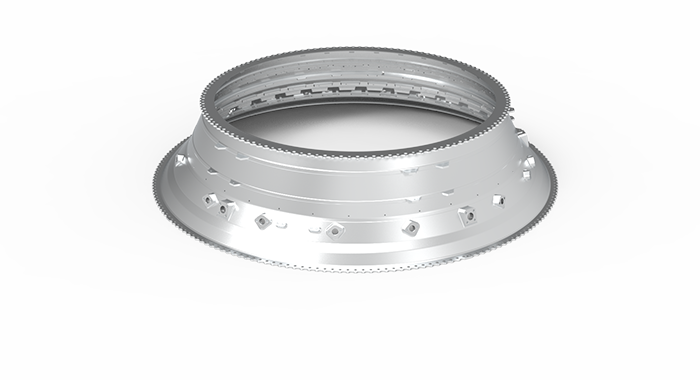

Application in Aerospace

Impeller, blisk, engine casing, single blade, closed blisk, vane ring, propeller, components with complex geometries, medical instruction components etc.

Impeller

Blisk

Engine casing

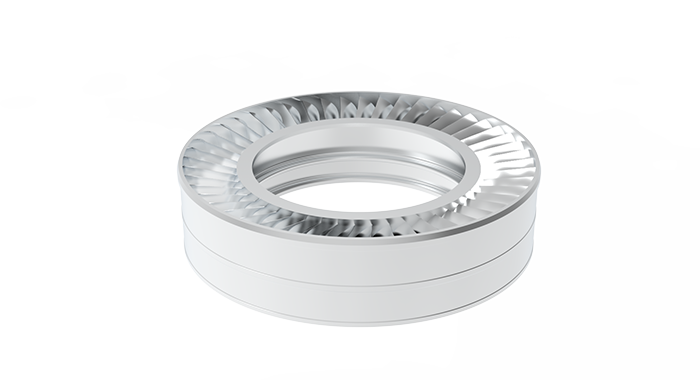

Vane ring

Core technology

Core technology —— direct drive linear motor

Non-mechanical transmission, non-backlash

High acceleration and deceleration, quick response time

Consistently high-precision

Low noise and vibration

Easy maintenance

In-house developed —— CNC control system

CATO’ s C80 CNC control system makes it possible for high-precision 5-axis simultaneous machining.

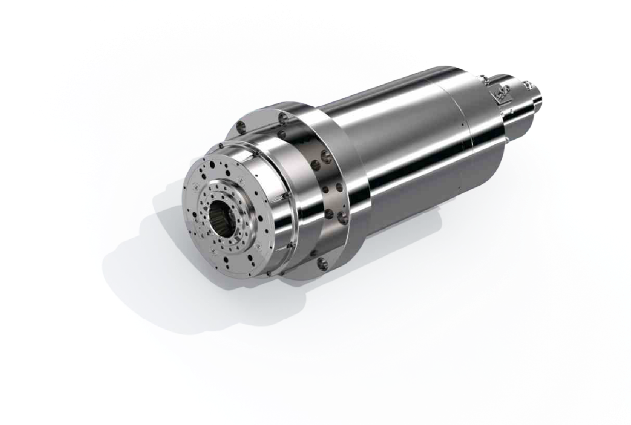

In-house developed —— spindle

CATO’ s in-house spindle workshop, operating in a controlled constant-temperature environment with a modular production line.

In-house developed —— swivel and rotary table

High speed

High rigidity

Mill-turn technique

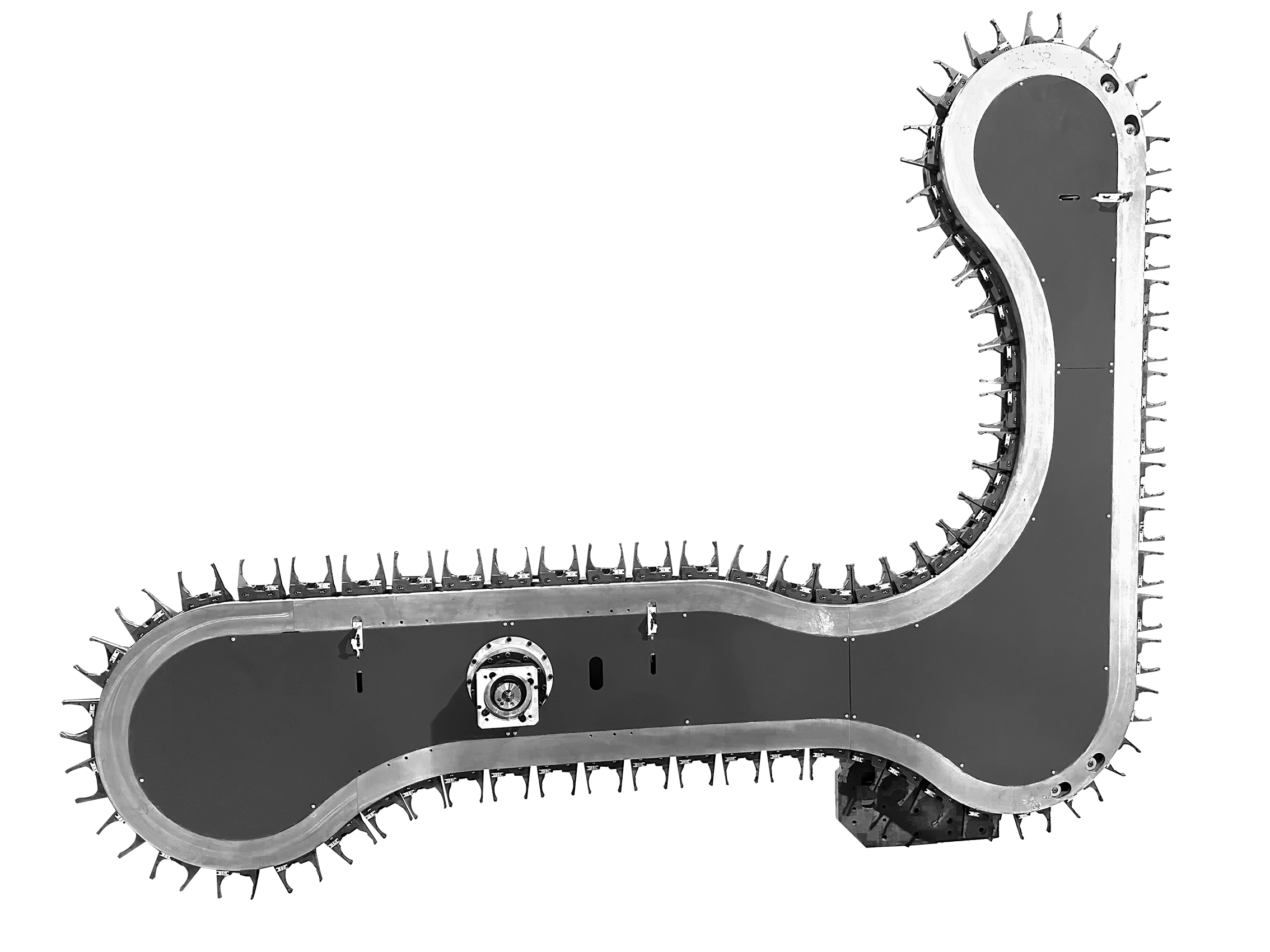

Core technology —— tool magazine

Variable in chain-type tool magazine, drum-type tool magazine, umbrella-type tool magazine etc.

Lower non-productive time

Higher reliability

#5-AxisMachiningCenter #CATO #Jugang Jinggong

Key words:

#5-AxisMachiningCenter,Aerospace,E-mobility

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638