Technology Empowers High-End Manufacturing! CATO CBS800 5-Axis Bridge Machining Center Makes a Grand Debut

Release time:

2025-10-22

Author:

CATO

Source:

Internet

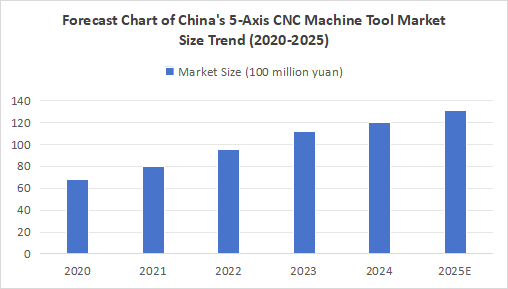

Driven by policies, the 5-axis machine tool market continues to expand, and is expected to reach 13.1 billion yuan by 2025. CATO has launched the CBS800 5-axis bridge-type machining center, which integrates linear motor and torque motor direct drive technologies, combined with a bridge-type high-rigidity structure, independently developed spindle system and direct drive turntable, achieving 20-nanometer-level precision machining. The equipment meets the processing needs of complex aerospace parts, precision medical devices, etc., featuring both high efficiency and high stability. It provides a full-process precision machining solution for high-end manufacturing enterprises, helping the industry transform and upgrade.

With the national promotion of large-scale equipment renewal, 5-axis machining technology has become a key support for the transformation and upgrading of aerospace, precision medical and other fields.

Against the backdrop of the accelerated intelligent and high-end transformation of the global manufacturing industry, 5-axis machining centers have become indispensable core equipment in high-end sectors such as aerospace, precision medical care and energy equipment. As a leading enterprise in China's CNC technology field, CATO (Guangdong) Co., Ltd. has launched the CBS800 5-axis bridge machining center, which provides new technical support for China's high-end manufacturing with a number of independent R&D achievements.

I. New Industry Opportunities: Policy-Driven Surge in Demand for 5-Axis Machine Tools

Recently, six ministries and commissions including the Ministry of Industry and Information Technology jointly issued the Work Plan for Stabilizing Growth in the Machinery Industry (2025-2026), which clearly proposes to promote the large-scale application of intelligent manufacturing equipment in aerospace and other fields. This policy orientation has brought strong momentum to the 5-axis machining center market.

Data Source: AskCI.com (WWW.ASKCI.COM)

According to industry data, the market size of China's 5-axis CNC machine tools is growing rapidly and is expected to exceed 13 billion yuan by 2025. This growth is mainly driven by the continuous increase in demand for complex component machining in industries such as aerospace and precision medical care.

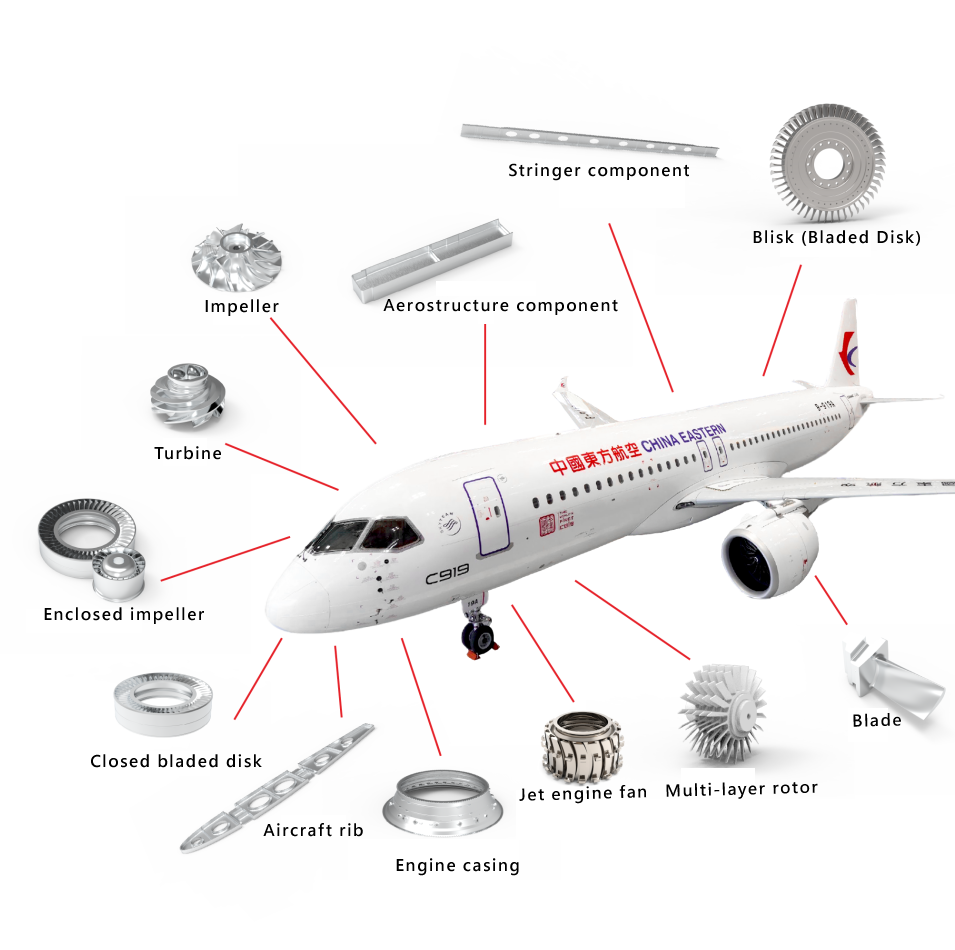

In the aerospace field, with the advancement of domestic large aircraft projects and the improvement of independent R&D capabilities for aero-engines, higher requirements have been put forward for the machining capabilities of complex parts such as impellers, blisks and casings. The demand for products such as artificial joints and surgical instruments in the precision medical industry has also promoted the widespread application of 5-axis machining technology.

II. Technological Breakthrough: Direct Drive Technology Becomes a New Benchmark for 5-Axis Machine Tools

Currently, direct drive technology has become the development direction of high-end CNC machine tools. China has made major breakthroughs in the field of direct drive technology; through a zero-transmission chain design, it has advanced machining accuracy to 20 nanometers, which is equivalent to one-thousandth of the thickness of a human hair.

Direct drive technology eliminates backlash in mechanical transmission, reshaping the boundaries of machine tools in terms of speed, precision and efficiency. This technological leap enables domestic high-end equipment to meet the extreme precision machining requirements of aerospace, military and other fields.

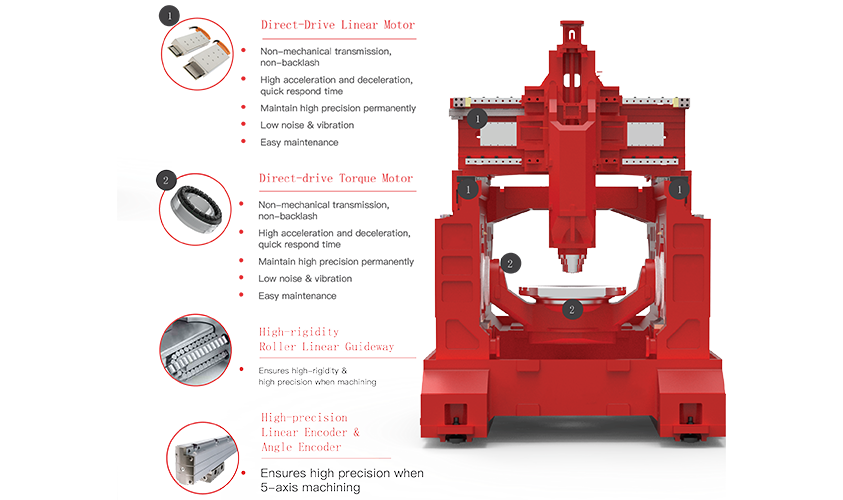

CATO has kept up with this technological trend and fully applied linear motor direct drive and torque motor direct drive technology in the CBS800 5-axis bridge machining center, achieving backlash-free and high dynamic response machining performance.

III. CATO CBS800: A 5-Axis Solution Born for High-End Manufacturing

1. Bridge-Type High-Rigidity Structure Lays the Foundation for Precision Machining

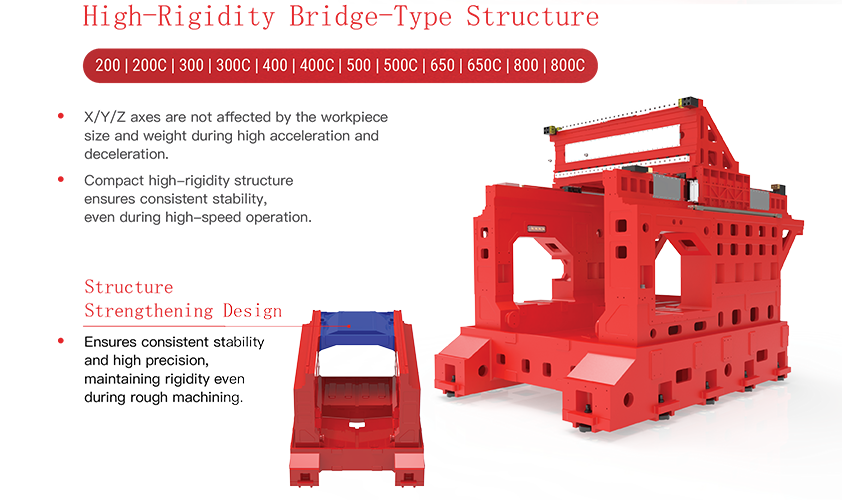

The CBS800 adopts a bridge-type high-rigidity structural design, with a stable overall structure and high rigidity that can withstand large workloads. This design ensures that the machining efficiency of the three axes is not affected by the size and weight of workpieces during high-speed acceleration and deceleration, providing a solid platform for high-precision machining.

The reinforced structural design further ensures the stability of the machine tool during high-speed machining; even under rough machining conditions, it can maintain high rigidity, realizing full-process precision control from rough machining to finish machining.

2. Linear Motor Direct Drive Technology Achieves Extreme Precision

The X/Y axes of the CBS800 adopt high-performance linear motor direct drive technology, combined with a high-precision grating scale feedback system, realizing excellent 5-axis simultaneous machining capabilities. Linear motor direct drive technology eliminates backlash and elastic deformation in mechanical transmission, providing higher system bandwidth and better dynamic performance.

This technological advantage enables the CBS800 to easily meet the high-precision machining requirements of complex curved surfaces in the aerospace field, greatly shortening the production cycle and improving machining efficiency.

3. Independent Spindle System Demonstrates Technical Strength

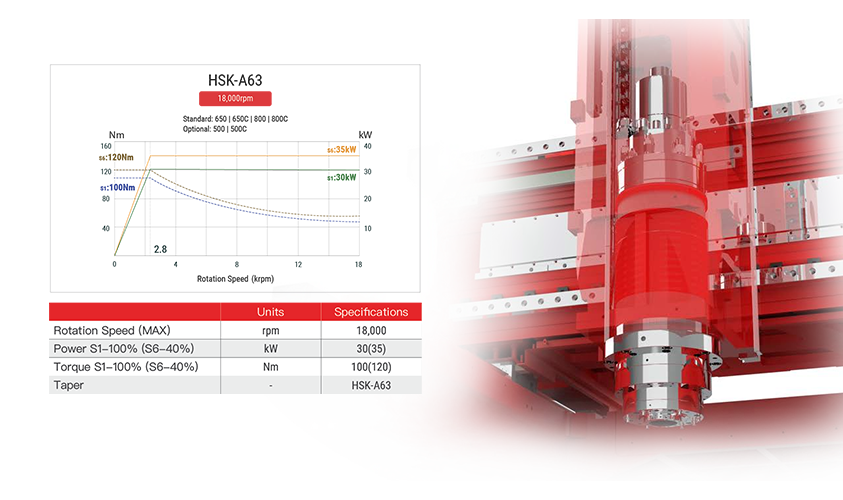

As the core of the whole machine, the built-in electric spindle independently developed by CATO offers multiple specifications including HSK-E40/A63/A100 to meet the needs of different machining scenarios. The spindle adopts a forced cooling system to perform real-time temperature control on the motor and front/rear bearings, ensuring precision stability during high-speed and long-term operation.

CATO masters core technologies and has spindle design, manufacturing and assembly capabilities. The constant temperature and humidity workshop and refined modular production model ensure that the spindle has the characteristics of high rigidity, high speed, high power, high torque and high reliability.

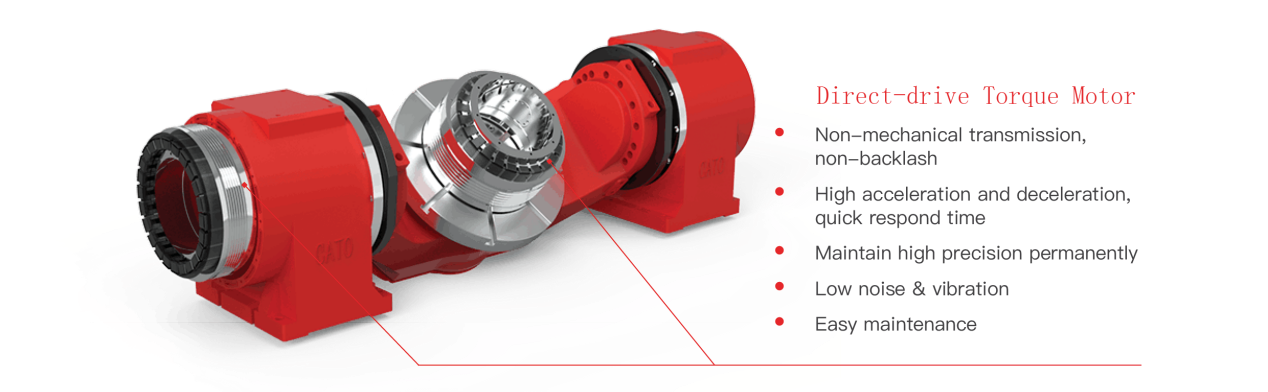

4. Direct Drive Turntable Enables True 5-Axis Simultaneous Machining

The CBS800 is equipped with an independently developed A/C axis precision cradle by CATO, adopting torque motor direct drive technology to achieve backlash-free and wear-free true 5-axis simultaneous machining. The direct drive turntable provides high dynamic response characteristics; its extremely fast acceleration and deceleration significantly reduce non-cutting time.

Combined with a high-precision encoder, this system achieves precise positioning and control during the machining process, providing technical support for the complete machining of complex parts such as impellers and blisks with one-time clamping.

IV. Application Fields: Meeting Precision Machining Needs of High-End Industries

In the aerospace field, the CBS800 can efficiently machine complex curved surface parts such as impellers, closed blisks, integral blisks and fan blisks, as well as key components including aero-engine casings, casing parts, spiral parts and turbine parts. Its high-precision characteristics meet the strict requirements for part quality in the aerospace industry.

With the rapid development of high-end manufacturing industries such as aerospace and precision medical care, and the strong promotion of intelligent manufacturing equipment by the state, the 5-axis machining center market has broad prospects. Relying on its characteristics of high rigidity, high precision and high efficiency, the CATO CBS800 5-axis bridge machining center is becoming the preferred equipment for many manufacturing enterprises.

V.Welcome to contact CATO to learn how the CBS800 5-axis bridge machining center can create value for your enterprise!

▷ Email: hujuzhen@catocnc.com

▷ Phone: +86 138-2920-2050

▷ For details, visit: https://en.catocnc.com/products_details/8.html

Key words:

Previous Page

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638