CATO CBS 650 5-Axis Bridge-Type Machining Center: Empowering a New Era of Aerospace and Medical Precision Manufacturing with Cutting-Edge Technology

Release time:

2025-09-02

Author:

CATO

Source:

Internet

As a national high-tech firm, CATO launches the CBS 650 5-axis bridge-type machining center, tailored for aerospace and medical sectors. Boasting high rigidity, linear motor drive, self-developed spindles, and strong 5-axis machining, it meets strict precision needs. With China’s 5-axis machine tool market set to grow, CATO, backed by full services, will keep innovating to aid manufacturing upgrading.

As the global manufacturing industry moves toward high-end and intelligent development, high-end CNC machine tools, as the "cornerstone" of the industrial system, are gaining increasing prominence. Especially in high-tech fields such as aerospace and medical devices, the requirements for machining accuracy, efficiency, and quality consistency of complex parts are extremely stringent.

As a national high-tech enterprise and a national-level "Specialized, Refined, Characteristic, and Innovative" Little Giant enterprise, CATO (Guangdong) Co., Ltd. has always adhered to the independent R&D of core technologies. The CBS 650 5-axis bridge-type machining center launched by the company is precisely a powerful tool created to meet the current market demand for high-end precision machining.

01 Industry Background and Opportunities

Currently, China's CNC machine tool industry is in a period of upgrading and breakthrough. Data shows that the penetration rate of high-end machine tools in China was only 9.2% in 2024, far lower than the over 50% level of manufacturing powerhouses such as the United States and Japan.

As a representative of high-end equipment, the localization process of 5-axis machine tools has attracted much attention. In 2024, the localization rate of 5-axis machine tools was approximately 55%, which still leaves significant room for improvement compared with the 75% localization rate of non-5-axis machine tools.

This also implies huge potential for domestic substitution. It is expected that by 2029, the market size of China's 5-axis machine tool industry will reach 27 billion yuan, with a compound annual growth rate (CAGR) of 20.1%, far higher than the overall 5.3% growth rate of the CNC machine tool industry.

The demand for high-precision and complex part machining in the aerospace and medical fields is an important driving force for the growth of the 5-axis machine tool market. Products in these fields usually feature complex curved surfaces, strict material requirements, and rigorous quality control standards.

Data Sources:【Click To Jump】

02 Core Product Advantages

CATO CBS 650 5-axis bridge-type machining center integrates a variety of advanced technologies and provides a comprehensive solution for pain points in the high-end manufacturing field.

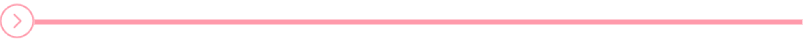

● High-Rigidity Bridge Structure Design: It adopts a unique bridge layout and a box-in-box symmetric beam structure, resulting in a stable overall structure and high rigidity. This enables the machine's three axes to maintain stable machining efficiency and accuracy during high-speed acceleration and deceleration movements, unaffected by the size and weight of the workpiece.

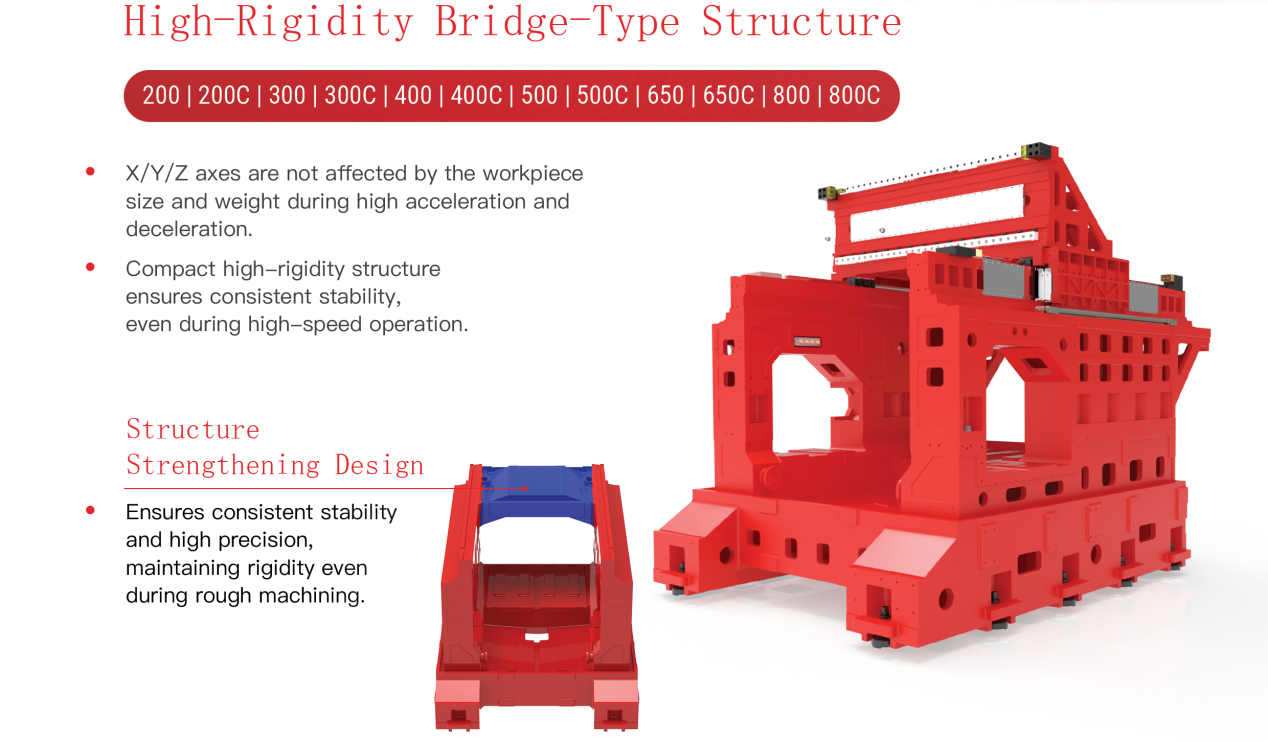

● Linear Motor Direct Drive Technology: The X-axis and Y-axis are driven directly by high-performance linear motors, with no mechanical transmission chain, completely eliminating the backlash issue. Combined with a high-precision grating scale feedback system, it can permanently maintain high-precision machining capabilities, meeting the extreme pursuit of machining accuracy and efficiency in the aerospace industry.

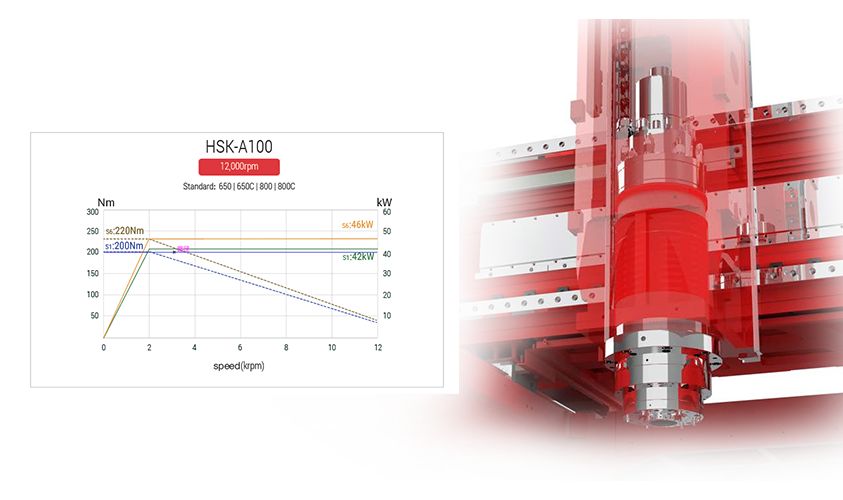

● Independently Developed Core Functional Components: CATO has mastered core technologies and possesses the capability of designing, manufacturing, and assembling spindles. The HSK-A100 built-in electric spindle, which is a standard configuration of the CBS 650, is manufactured in a constant temperature and humidity workshop using a fine modular production mode. It features high rigidity, high speed (up to 12,000 rpm), high power, large torque, and high reliability.

● Powerful 5-Axis Simultaneous Machining Capability: The A-axis has a rotation angle of ±110°, and the C-axis has a rotation angle of 360°. The XYZ-axis travel is 650×800×560 mm. Combined with a tool magazine with a capacity of 30 tools (tool change time is only 7 seconds) and the performance of the three axes with a rapid traverse speed of up to 48 m/min, it can efficiently complete 5-face machining of complex parts and full machining with one-time clamping.

03 Application Scenarios and Value

CATO CBS 650 5-axis bridge-type machining center demonstrates excellent performance in a number of high-end manufacturing fields:

● Aerospace Field: Addressing the high-precision machining needs of key parts such as impellers, closed blisks, integral blisks, and aero-engine casings, the equipment can ensure excellent surface quality and dimensional consistency.

● Medical Device Manufacturing: It is suitable for the machining of precision medical parts such as implants and surgical instruments, meeting the strict requirements of the medical industry for material specificity and surface finish.

● High-Precision 5-Axis Part Machining: Relying on its stable accuracy and efficient machining capabilities, it has become a reliable choice for the mass production of precision parts.

04 Systematic Support and Services

CATO not only provides high-performance equipment but also has built a complete service system. The CBS 650 offers a variety of mainstream CNC system options, including Heidenhain TNC 640 and C80 Plus, among which Siemens Sinumerik One is the standard configuration, catering to the operating habits and functional needs of different users.

05 Market Prospects and Outlook

With the national policy attaching great importance to industrial machine tools and the acceleration of the domestic substitution process of high-end CNC machine tools, leading domestic enterprises represented by CATO are embracing development opportunities.

In the future, CATO will continue to adhere to independent innovation, deepen its presence in high-end fields such as aerospace, new energy vehicles, and medical equipment, and provide more high-performance and high-reliability machining solutions for the transformation and upgrading of China's manufacturing industry.

As a national high-tech enterprise, a national-level "Specialized, Refined, Characteristic, and Innovative" Little Giant enterprise, and a Guangdong Provincial Manufacturing Single Champion Enterprise, CATO has always been committed to the R&D and manufacturing of high-end CNC equipment.

The company's CBS series 5-axis bridge-type machining centers have been widely used in high-end manufacturing fields such as aerospace, new energy vehicles, and medical equipment. With their high rigidity, high precision, and high efficiency machining performance, they provide an ideal solution for customers to improve production efficiency and reduce comprehensive costs.

To learn more about how the CBS 650 5-axis bridge-type machining center can boost your precision manufacturing business, please contact CATO's professional team to obtain detailed technical materials and customized solutions.

▷ Email: hujuzhen@catocnc.com

▷ Phone: +86 138-2920-2050

▷ For details, visit: https://en.catocnc.com/products_details/7.html

Key words:

Five-axis bridge type machining center,5-axis bridge type machining center,High-end CNC machine tools,Aerospace manufacturing (impellers, integral blisks, engine casings),Medical device manufacturing (implants, surgical instruments),High-precision 5-axis parts processing

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638