CATO's CV Five Axis Vertical Machining Center Helps Upgrade New Energy Vehicles and Aerospace Manufacturing

Release time:

2025-07-04

Author:

CATO

Source:

Internet

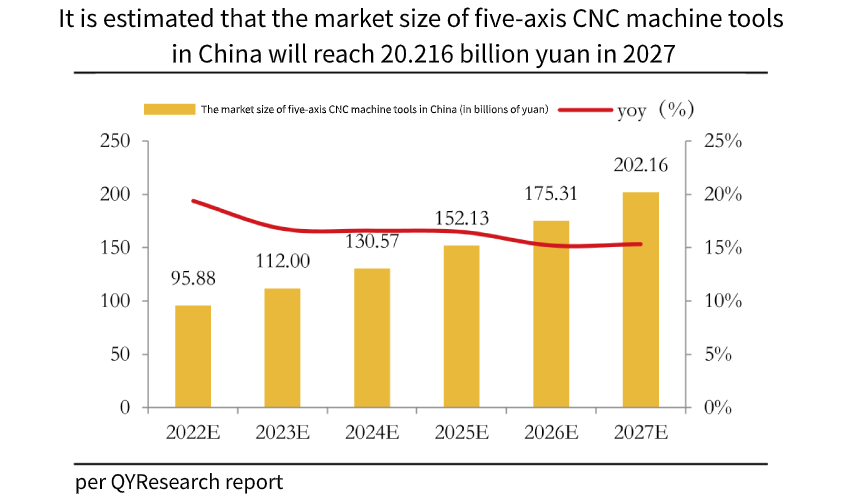

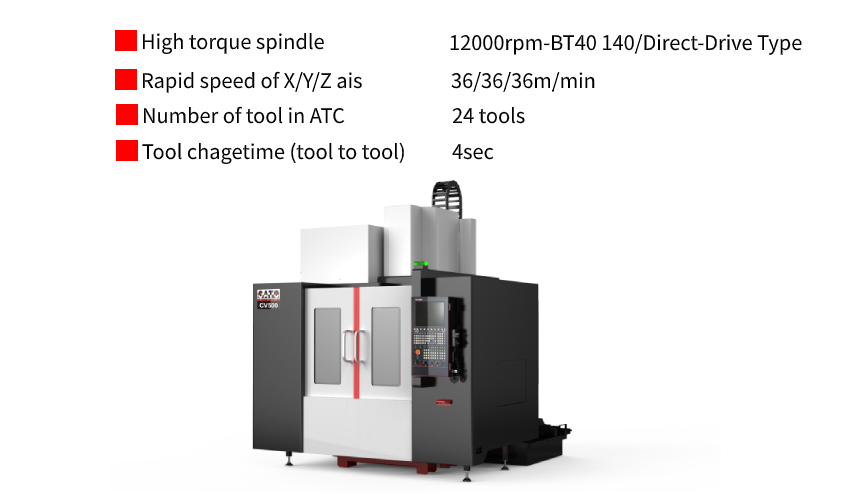

In 2025, China's new energy and aerospace sectors emerged as dual drivers for upgrading high-end manufacturing, fueling surging demand for five-axis machine tools (16% CAGR). CATO Precision Machinery entered the market with high-performance equipment featuring 4-second tool changes and 36 m/min rapid traverse speeds. By tackling technical bottlenecks through industry alliances and leveraging policy incentives, CATO accelerated the replacement of imported high-end equipment and expanded domestic industrial cluster deployments.

In 2025, China's new energy vehicle penetration rate surpassed 35%, driving surging demand for lightweight aluminum components (wheels, steering knuckles) and integrated die-casting molds, while pushing machining precision into the ±0.005mm era. Simultaneously, accelerated progress in domestic aircraft programs has heightened reliance on five-axis machine tools for complex parts like titanium aerospace structural components and diffusers. Industry projections indicate China's five-axis CNC machine tool market will reach RMB 20.216 billion by 2027, with a 16.09% CAGR, over 60% of which will be fueled by the new energy vehicle and aerospace sectors.

The machine features rapid traverse speeds of 36 m/min across all three axes (X/Y/Z) and achieves an impressive tool-to-tool change time of just 4 seconds. Its reliability has been rigorously verified through 24-hour continuous operation with a fully loaded 24-tool magazine (zero alarms) and three-coordinate measurement of test samples from each unit, ensuring consistent high-performance stability after delivery. This versatile system is capable of machining complex 2D/3D contours, intricate cavities, and sophisticated surfaces, making it ideal for manufacturing various components including valves, cams, molds, plates, panels, and gearboxes through milling, drilling, boring, reaming, and tapping operations. It's equally suitable for small-to-medium batch production with frequent changeovers as well as integration into automated mass production lines.

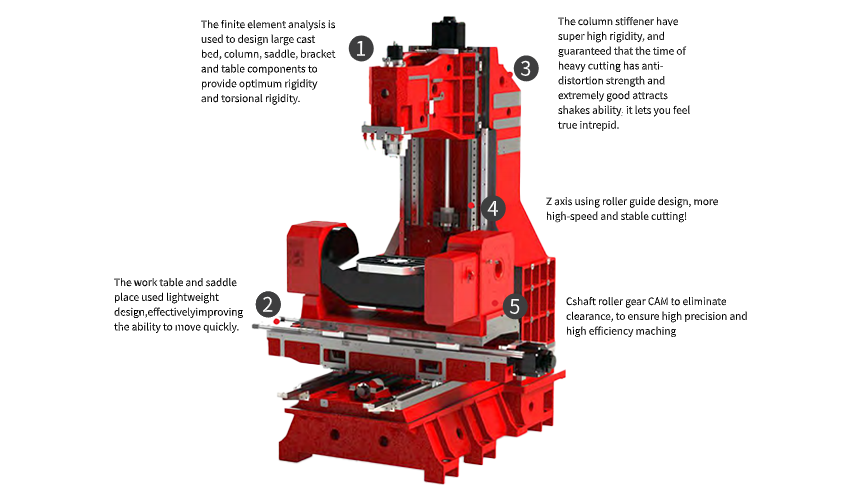

High rigidity structual design

Improve the form of structure and optimize the allocation to enhance the machine's rigidity. The shape of machine tool and column and the allocation optimization are the most suitable shape through CAE analysis.

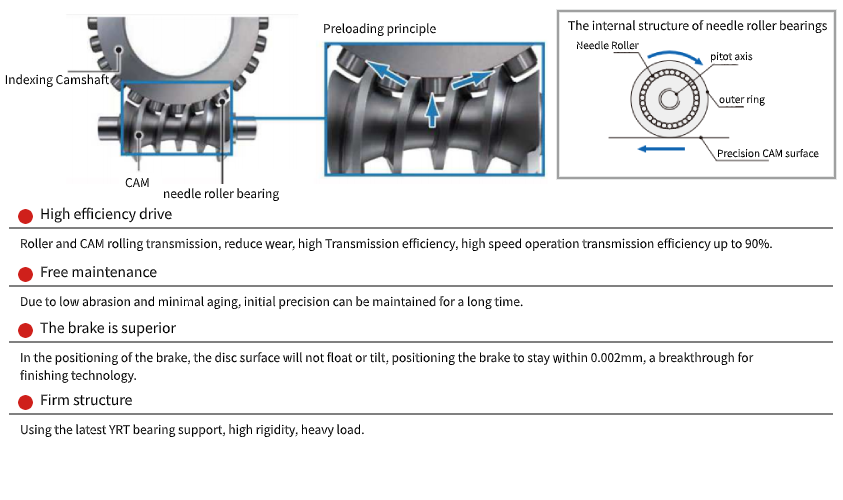

Roller Cam Rotary Table Comes Standard with C300/CV500 Models

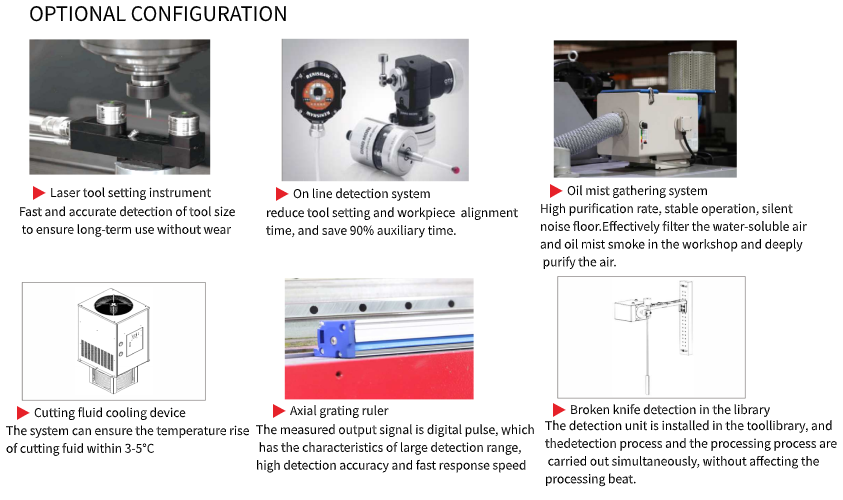

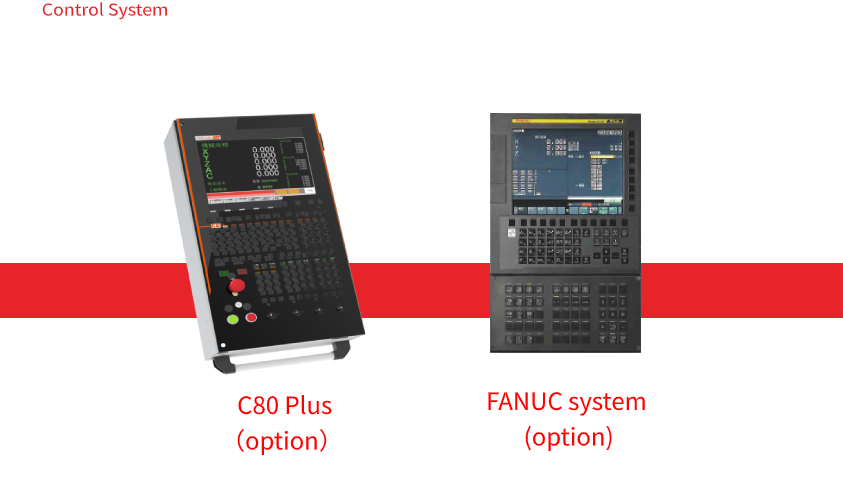

Optional Configuration

Industrial application: Solving manufacturing pain points

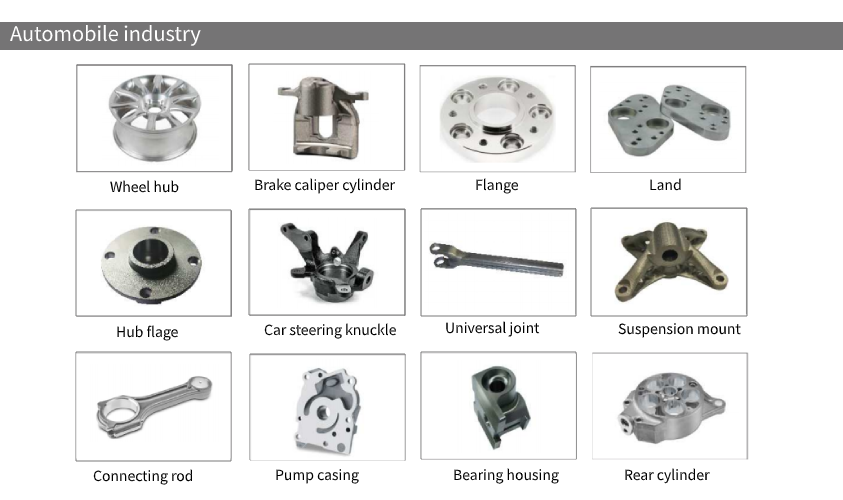

Automobile industry

Precision fixture

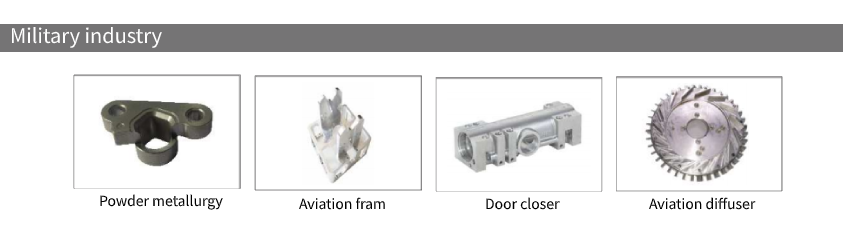

Military industry

Ecological layout: Innovation consortium promotes technological breakthroughs

In March 2025, CATO Precision Machinery will lead the establishment of the "Dongguan Industrial Mother Machine and Mold Innovation Alliance", which will collaborate with upstream and downstream enterprises and universities in the industrial chain. The initial investment will be 130 million yuan, with a focus on tackling bottleneck technologies such as hot pressing molds for new energy vehicles and five axis CNC machining centers, with an expected increase in output value of 2 billion yuan. The Yinchuan Smart Factory, which is being constructed synchronously, will be put into operation in October, accelerating the formation of a high-end manufacturing cluster in Northwest China.

Policy dividend: New Opportunities in the wave of equipment renewal

In 2025, the country will implement a large-scale equipment renewal policy, support the upgrading of high-end and intelligent equipment in industry through ultra long term special treasury bond, and focus on new energy vehicles, aerospace and other fields. The CATO's CV series has become the preferred choice for enterprise equipment updates due to its high cost-effectiveness and domestic technological advantages (such as the self-developed C80 Plus system), and has been purchased in bulk by multiple leading manufacturers.

Key words:

Previous Page

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638