CATO Precision's CBS series five-axis bridge-type machining centers: In line with industry hotspots and leading manufacturing transformation

Release time:

2025-06-30

Author:

CATO

Source:

Internet

Under the background of high-end and intelligent manufacturing, CATO Precision Machinery has launched the CBS series of five-axis bridge-type machining centers. With advanced technologies such as box-in-box crossbeams and multiple control systems, it empowers fields like aerospace and has become the focus of the industry.

In the wave of transformation and upgrading in the manufacturing industry, advanced processing technologies and equipment are the key to industrial breakthroughs. Recently, China's manufacturing industry has achieved remarkable results in fields such as aerospace and high-end equipment. For instance, the manned lunar exploration project has been steadily advancing, related industries have flourished, and the demand for high-end processing equipment has increased dramatically. Against this backdrop, the CBS series of five-axis bridge-type machining centers launched by CATO Precision Machinery.

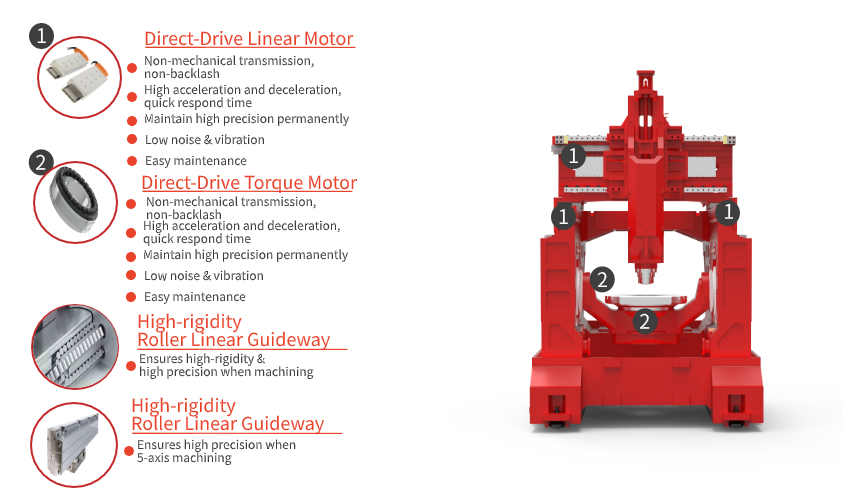

Cutting-Edge Technology Underpins High-End Manufacturing Demands

In today's landscape, high-end manufacturing imposes stringent requirements on machining precision and efficiency. The CBS series five-axis gantry machining center responds precisely, featuring an innovative box-in-box symmetrical crossbeam design. This structure stabilizes the spindle center by minimizing thermal displacement, significantly enhancing machine tool rigidity, and ensuring precision remains unaffected by ambient temperature—laying a solid foundation for high-precision machining. In aerospace component manufacturing, thermal displacement control is critical to ensuring part performance. This design aligns with this industry hotspot, guaranteeing precision and stability of key components under complex operating conditions.

The direct drive technology of X/Y axes with high-performance linear motors, paired with a high-precision grating scale feedback system, represents another technical highlight of the CBS series. This combination enables five-axis simultaneous machining with ultra-high response speed, perfectly meeting the aerospace and high-precision parts manufacturing sectors' ultimate pursuit of machining accuracy and efficiency. For instance, in processing complex curved surface parts like impellers and blisks, errors can be precisely controlled within the micrometer range, drastically improving product quality and production efficiency to help enterprises stand out in fierce market competition.

Independently Developed Spindle Meets Industry's Efficient Production Trend

As industries increasingly demand efficient production, the performance of core components in machining equipment becomes critical. CATO Precision Machinery's independently developed HSK-E40/HSK-A63/HSK-A100 built-in electric spindles effectively eliminate runout and vibration during rotation, ensuring precision stability during prolonged high-speed machining. The spindle employs forced cooling technology to safeguard the reliability of the motor and front/rear bearings under heavy loads. Manufactured in a constant temperature and humidity workshop using fine modular production, the spindle boasts high rigidity, high speed, high power, large torque, and high reliability—meeting the urgent needs of aerospace and high-end equipment manufacturing industries for efficient, high-precision machining, and providing robust support for enterprises to achieve scaled, high-quality production.

Diverse Applications Align with Industrial Development Hotspots

In the aerospace industry, the CBS series five-axis gantry machining center fully demonstrates its advantages. Currently, the aerospace industry is evolving toward high-performance and lightweight directions, with escalating requirements for component machining precision and quality. The CBS series can efficiently process key components such as Impeller, Vane ring, Round blisk, fan blisk, Fan blade, Engine casing, ensuring product quality, enhancing production efficiency, and meeting the industry's rapid development needs. Take China's manned spaceflight project as an example: the manufacturing of spacecraft components requires extremely high precision, and the CBS series machining center provides reliable technical support to boost the steady advancement of China's space industry.

In the high-end equipment manufacturing sector, the trends of industrial intelligence and precision are evident. With its robust machining capabilities and stable performance, the CBS series machining center meets the processing needs of complex components, providing strong support for industry technological upgrading and product innovation. For instance, in the manufacturing of new energy vehicle core components, where extremely high precision and consistency are required, the CBS series ensures machining accuracy, enhances product performance, and drives the development of the new energy vehicle industry.

Diverse Control Systems Adapt to Intelligent Manufacturing Trends

Intelligent manufacturing represents the inevitable trend of the manufacturing industry, making the control system— the "brain" of machining equipment—crucial. The CBS series machining center offers diversified choices: Heidenhain TNC 640 is renowned for precise control, C80 Plus integrates CATO Precision Machinery's innovative technologies, and Siemens Sinumerik One, as the standard configuration, features high stability and rich functional modules. This diversified configuration aligns with the intelligent manufacturing requirements for system flexibility, compatibility, and intelligence. Users can flexibly select based on their production processes, operation habits, and budgets to enhance equipment intelligence and strengthen enterprise competitiveness in the intelligent manufacturing era.

In recent years, the state has strongly supported high-end manufacturing, leading to rapid development in aerospace, high-end equipment manufacturing, and other industries. According to National Bureau of Statistics data, the scale and profits of related industries have significantly increased, driving sustained growth in demand for high-end machining equipment. With its advanced technology, excellent performance, and broad application fields, the CATO Precision Machinery CBS series five-axis gantry machining center conforms to industry development hotspots, will play a key role in industrial upgrading, lead new industry development trends, contribute to the high-quality development of China's manufacturing industry, and help accelerate China's transformation from a manufacturing power to a manufacturing superpower.

Key words:

CATO cnc,Bridge type five axis maching center,Three-axis machining center,CATO Precision Machinery,Chinese CNC machine tool munufactures

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638