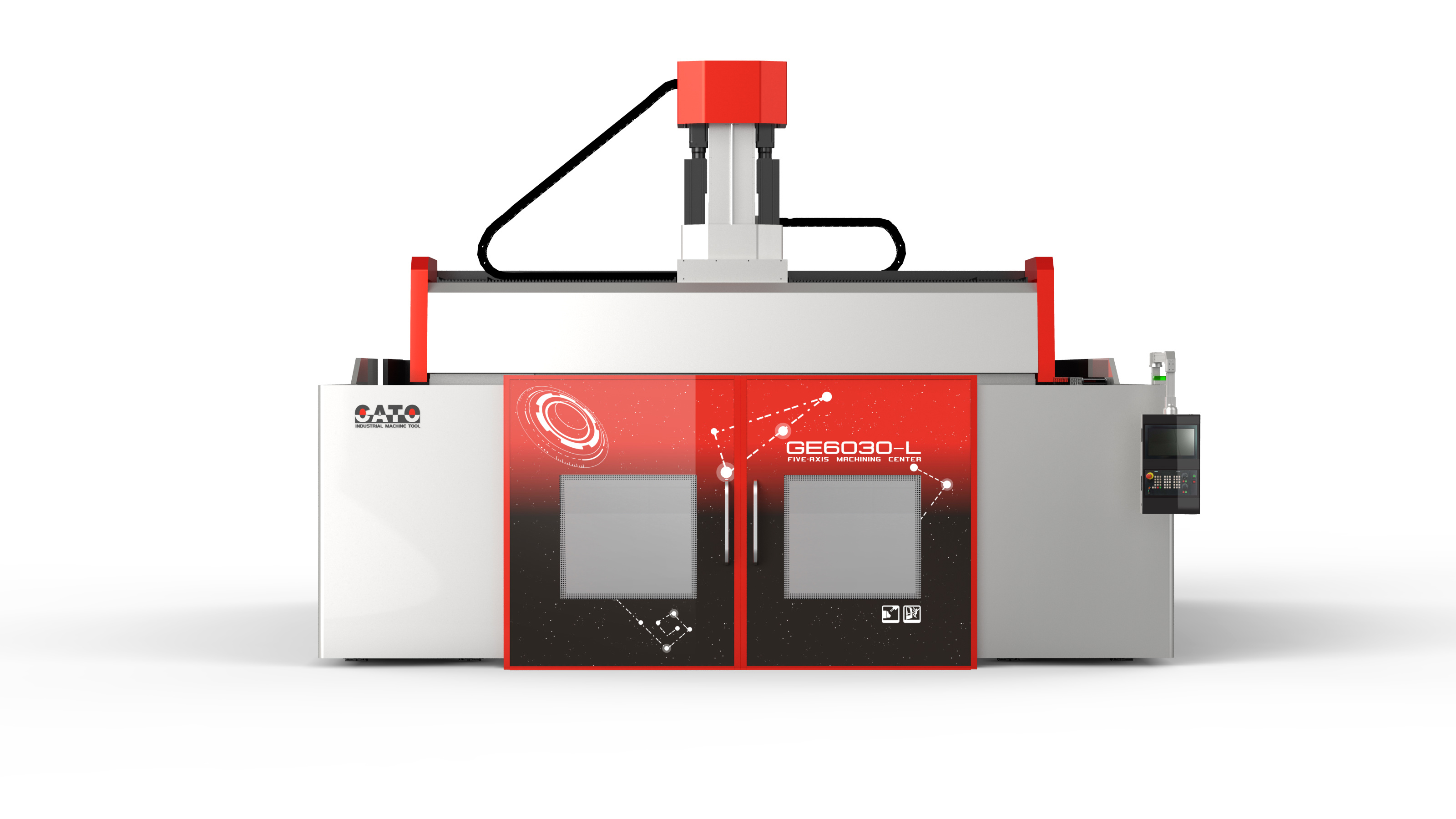

The GE five-axis gantry machining center of CATO Precision Machinery leads the industry transformation and contributes to the take-off of two major industries

Release time:

2025-06-27

Author:

CATO

Source:

Internet

Under the background of the transformation and upgrading of the manufacturing industry, the GE five-axis gantry machining center launched by CATO Precision (Guangdong) Co., Ltd. has become the focus. The equipment is technologically advanced and suitable for the aerospace and automotive stamping die industries. It is equipped with a diversified control system, injecting impetus into the high-quality development of the industry.

Against the backdrop of the manufacturing industry's accelerated transformation and upgrading, and the surging demand for high-precision, high-performance machining equipment, CATO Precision Machinery (Guangdong) Co., LTD. has become the industry focus by launching its GE five-axis gantry machining center, leveraging its innovative strength. This equipment not only integrates advanced technologies but also demonstrates exceptional machining capabilities in two key sectors: aerospace and automotive stamping molds, injecting new impetus into industry development.

Advanced Technologies Create Superior Performance

The GE five-axis gantry machining center stands out with its technological highlights. Its box-in-box symmetrical crossbeam structure design is a major innovation, effectively stabilizing the spindle center, significantly reducing thermal displacement, ensuring spindle stability during machining, and enhancing the machine tool's rigidity. Notably, this design makes precision less susceptible to environmental temperature changes, thus significantly improving the machine tool's accuracy and stability—providing a solid foundation for high-precision machining. The integrated high-rigidity column structure design is equally remarkable: during high acceleration/deceleration movements of the three axes, machining efficiency remains unaffected by workpiece size or weight. The stable overall structure and excellent rigidity enable it to withstand heavy workloads, ensuring that machining quality is not compromised by workpiece weight even during high-speed X/Y/Z axis movements.

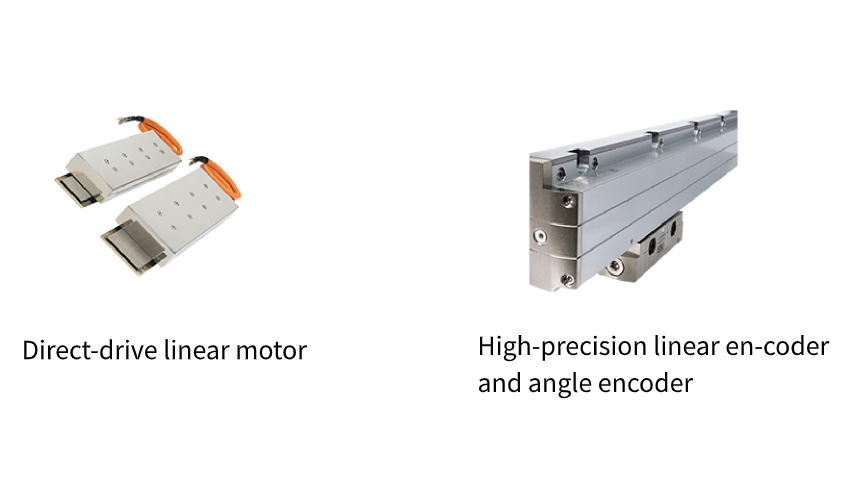

In terms of the drive system, the X/Y axes adopt high-performance linear motor direct drive technology, paired with a high-precision grating scale feedback system (resolution: 0.01μm). This combination achieves excellent five-axis simultaneous machining capabilities, perfectly meeting the aerospace industry and high-precision parts manufacturing fields' ultimate pursuit of machining precision and efficiency. In practical applications, it can accurately complete the machining of complex surfaces and precision components, significantly boosting production efficiency and product quality.

Efficient Machining Solutions for Two Key Industries Aerospace Industry

In the aerospace industry, this machining center has demonstrated its capabilities. The processing of key components such as aircraft rib plates, aircraft ribs, aircraft structural components, and aircraft skins requires extremely high precision and stability. The GE five axis gantry machining center, with its own advantages, can efficiently and accurately complete the processing of these components, helping aerospace companies improve production efficiency, ensure product quality, and meet the growing demands of the industry. With the successful commercial operation of domestically produced large aircraft for two years and the launch of the manned lunar exploration project's moon landing phase, the aerospace industry has entered a period of rapid development, and the demand for related processing equipment is constantly increasing. This equipment from Jugang Precision will undoubtedly play an important role in it.

Automotive Stamping Mold Industry

In the automotive stamping die industry, GE five-axis gantry machining centers have also performed outstandingly. This equipment can easily handle the processing of top stamping dies, cover stamping dies, side tail stamping dies and other molds, as well as commonly used P20 die steel materials. Its powerful processing capacity and stable performance ensure the high precision and high efficiency of mold processing, providing strong support for automotive stamping mold enterprises to enhance their competitiveness. At present, the automotive industry is in a stage of rapid development and transformation. The demand for automotive stamping dies is not only continuously increasing in quantity, but also the requirements for quality and precision are getting higher and higher. The equipment of Jugang Precision Machinery precisely meets this market trend.

Independently Developed System Enhances Competitiveness

The GE five-axis gantry machining center offers versatile control system options, including industry-leading Heidenhain (TNC640), Siemens, and CATO's independently developed C80 Plus system. The C80 Plus CNC system features RTCP (Rotational Tool Center Point) functionality, enabling multi-axis high-precision, high-speed control with multiple monitoring methods and modular functions for five-axis simultaneous machining. Its efficiency and precision reach world-class standards. The in-house developed system not only demonstrates CATO's technical strength but also provides users with diversified, tailored choices—further enhancing the equipment's market competitiveness.

As data from the National Bureau of Statistics shows, China's aerospace, aviation, and navigation industries ("three avigations") grew rapidly from January to May, driving a 56.0% year-on-year profit increase in railway, shipbuilding, aerospace, and aviation sectors. With the automotive industry's continuous innovation, the manufacturing sector's demand for high-end machining equipment is on the rise. CATO Precision Machinery's GE five-axis gantry machining center, with its advanced technologies, superior performance, and broad application scope, is set to occupy a key position in the industry, leading new trends in development and contributing to the high-quality growth of China's manufacturing sector.

Key words:

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638