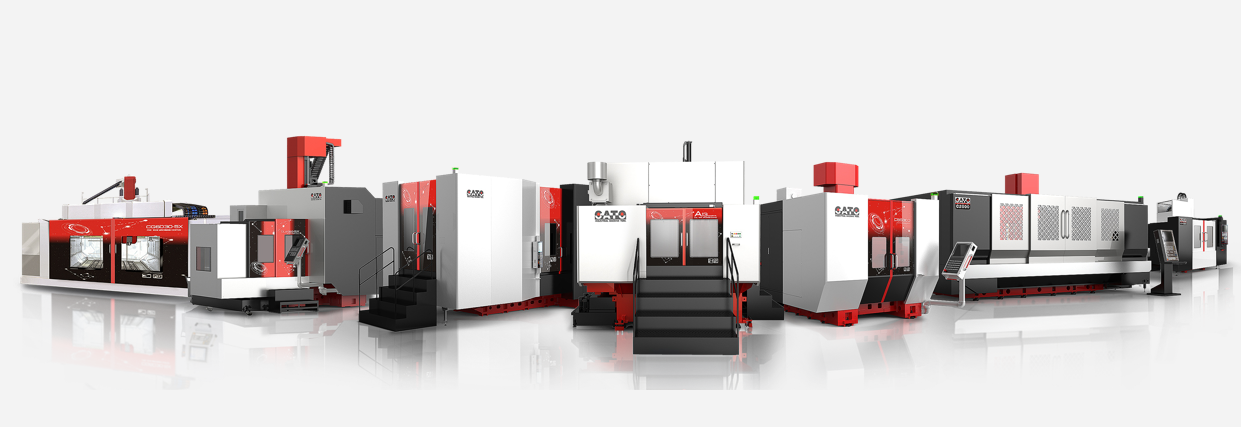

CATO Precision’s A13 five-Axis Horizontal Machining Center: Empowering New Energy Vehicle Component Manufacturing

Release time:

2025-08-13

Author:

CATO

Source:

Internet

The CATO Precision A13 five-axis horizontal machining center is suitable for processing die-cast aluminum alloy parts for new energy vehicles and can handle rear floors, motor housings, etc. XYZ travel: 1300, 800, 650. Precise drive of A/B axes. Spindle speed: 18,000 RPM. Tool change: 4 seconds. Three-axis speed: 90m/min. The high-rigidity structure supports multi-axis linkage, ensuring precision and efficiency, and facilitating the manufacturing of new energy vehicles.

Industry News: CATO Precision’s A13 5-Axis Horizontal Machining Center: Empowering New Energy Vehicle Component Manufacturing Precision’s A13 5-Axis Horizontal Machining Center: Empowering New Energy Vehicle Component Manufacturing

Precision Machining of Die-Cast Aluminum Parts – Accelerating NEV Production Efficiency

With the accelerated development of the New Energy Vehicle (NEV) industry, demand for high-precision, efficient machining of critical components—especially die-cast aluminum parts—has surged. CATO Precision (Guangdong) Co., Ltd. introduces the A13 5-axis horizontal machining center, specifically tailored to meet the stringent manufacturing requirements of NEV components.

The A13 excels at machining core NEV parts such as rear floor panels, sub-frames, motor housings, shock absorber towers, and torque boxes—all made from die-cast aluminum alloy.

I. Robust Performance Backed by Precise Specifications:

Machining Range: XYZ travels 1300×800×650 mm; A-axis rotation +90° to -180°, B-axis rotation 360°; equipped with Ø420 positioning plate; max. load capacity 1000 kg.

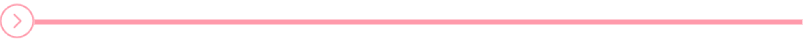

High Efficiency: Spindle (self-developed A63 built-in motor spindle) with HSK-A63 interface, reaching 18,000 RPM; 41-tool magazine with 4-second tool change; rapid traverse speed of 90 m/min and acceleration of 1G across three axes.

II. Precision and Stability:

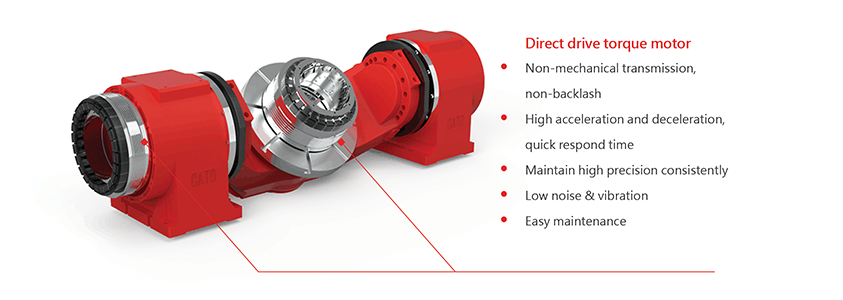

- A/B axes feature a self-developed trunnion table.

- Direct drive by torque motors eliminates mechanical transmission, ensuring zero backlash and zero wear.

- Maintains permanent high precision and enables low-noise operation during high acceleration/deceleration.

- Paired with high-precision encoders for accurate positioning and control throughout machining.

III. Flexible Configuration for Diverse NEV Manufacturing Needs:

Controller: Standard Siemens Sinumerik One, with optional Siemens 828D or C80 Plus.

Axis Options: Customizable.

Leveraging core technologies in spindle design, manufacturing, and assembly—supported by constant-temperature/humidity workshops and refined modular production—the A13 delivers high rigidity, high speed, high power, and exceptional reliability, perfectly aligning with the NEV industry’s pursuit of efficiency and precision.

For more details on how the A13 enhances NEV component manufacturing, visit our official website or contact our technical team today.

▷ Learn more: https://en.catocnc.com/products_details/11.html

▷ Technical consultation: +86 138-2920-2050

Key words:

Longmen processing center,Bridge type five axis machining center,machining center manufacturer,Five axis CNC machine,horizontal machining center,NEV parts manufacturing,die-cast aluminum machining,high-precision CNC,CATO CNC,A13 HMC

Previous Page

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638