Axis Vertical Machining Centers: Troubleshooting and Rapid Repair Strategies for Tool Magazine Failures

Release time:

2025-08-20

Author:

CATO

Source:

Internet

5-axis vertical CNC machining centers are vital in precision manufacturing, yet tool magazine failures disrupt production. Causes include poor tool installation, electrical issues, and mechanical faults. Solutions: correct mounting, cleaning, checking parts. Holistic checks and repairs reduce downtime. CATO provides advanced equipment and support.

Vertical 5-axis CNC machining center play a vital role in precision manufacturing due to their efficient multi-axis synchronization capabilities. However, tool magazine failures inevitably disrupt machining processes, significantly impacting production schedules and product quality. To ensure stable equipment operation, systematic analysis of tool change failures and mastery of scientific solutions are critical.

I. Failures Caused by Improper Tool Installation and Magazine Management

Incorrect tool installation or poor magazine management are common causes of tool change failures. If tools are not securely mounted on tool holders, they may detach during changes, potentially causing severe equipment damage. Overweight tools or those exceeding the load capacity of the change mechanism will also lead to failure. Therefore, tool installation must strictly follow procedures. Ensure tight fit between tools and holders using torque wrenches. Regularly inspect tool specifications and weight in magazines. Prevent debris buildup. Chips and oil sludge in holders and mechanisms hinder tool loading and unloading. Implement scheduled cleaning to maintain internal cleanliness.

II. Tool Change Abnormalities from Electrical Control System Failures

The tool change process relies on coordinated operation of sensors, relays, servo motors, and other electrical components. Key electrical failures include faulty position sensors or poor signal transmission. Verify signals with multimeters and oscilloscopes. Replace damaged sensors promptly. Loose or broken wiring. Inspect connections and repair compromised lines. Servo drive parameter errors or PLC logic flaws. Recheck drive parameters for motion synchronization. Debug and correct PLC programming errors.

III. Mechanical Transmission Component Failures: Primary Cause of Tool Change Issues

Mechanical abnormalities are the most frequent source of tool magazine failures. Critical components like indexing mechanisms, drive chains, and ball screw assemblies wear or loosen over time. Worn indexing pins cause misalignment with spindles. Inspect wear quarterly. Replace severely worn pins and bearings. Recalibrate indexing plate positioning. Loose or broken drive chains. Adjust tension or replace chains. Ball screw backlash. Eliminate through preload adjustment or replacement.

IV. Comprehensive Inspection and Precision Repair: Keys to Reliable Tool Changing

Resolving tool magazine failures requires holistic approaches spanning mechanical, electrical, hardware, and software domains. Through root cause analysis and targeted solutions, normal tool change functionality can be restored, ensuring machining center efficiency and stability. This methodology minimizes downtime while enhancing productivity and quality.

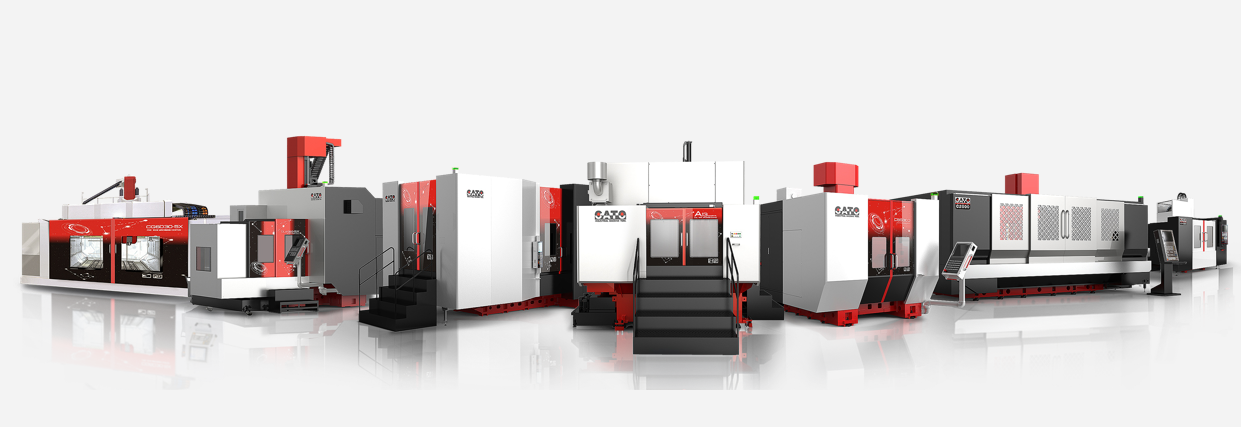

V. About CATO

Founded in 2006, CATO is a national high-tech enterprise focusing on the research and development, manufacturing, sales, service and talent strategy of high-end CNC equipment. Its headquarters is located in Dongguan, a world-famous manufacturing city, with a total construction area of about 50,000 square meters. With strong technical strength and brand competitiveness, the company has successively won honors such as "National High-tech Enterprise", "Guangdong Private Technology Enterprise", "Guangdong Famous Brand Product", "Guangdong High-tech Product", and "CNC Generation Demonstration Product".

The intelligent machine tools produced by CATO include more than 70 models in 14 series, including five-axis bridge machining center, five-axis horizontal cradle machining center, five-axis fixed beam gantry machining center, five-axis overhead crane machining center, five-axis horizontal swing head machining center, five-axis vertical machining center, and five-axis moving column vertical machining center. The outstanding performance of high speed, high precision, intelligence and networking for the automotive, 3C, aerospace, medical equipment and other industries has been widely praised by industry users.

▷ For details, visit: https://en.catocnc.com/products_details/15.html

▷ Technical consultation: +86 138-2920-2050

Key words:

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638