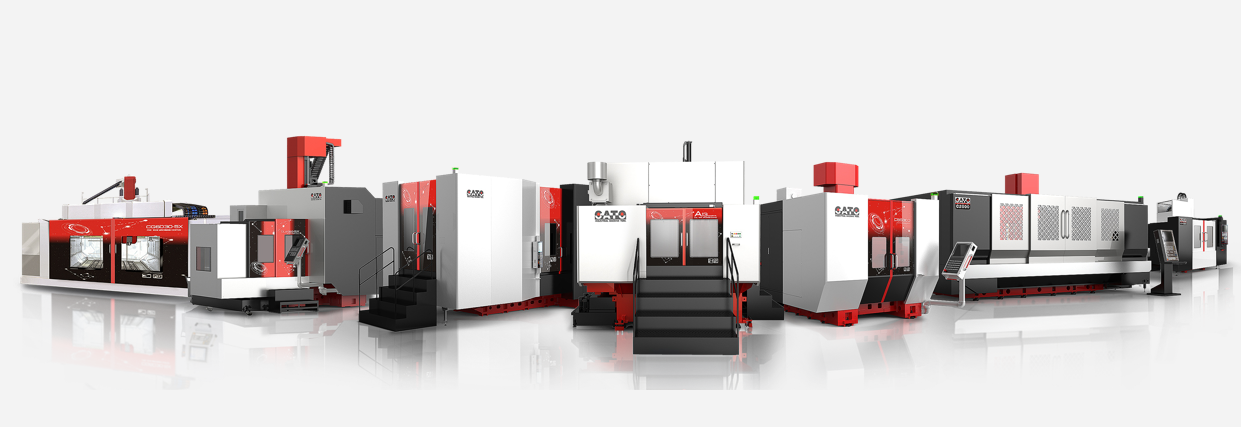

CNC Horizontal Machining Centers Adapting to High-Humidity Environments in Southeast Asia

Release time:

2025-08-19

Author:

CATO

Source:

Internet

The high-humidity environment in Southeast Asia poses challenges to CNC horizontal machining centers, easily causing corrosion, damaging components, and affecting precision. To address this, humidity should be controlled between 40% and 60% using dehumidifiers; temperature should be regulated within 15-25°C with air conditioners and other devices; reasonable layout is needed to avoid moisture and airflow, along with proper ventilation; corrosion-resistant materials and coatings should be adopted; and regular maintenance should be conducted. These measures can ensure the stable operation of the equipment.

The high humidity in Southeast Asia poses unique challenges to CNC horizontal machining centers. Moisture in the air can accelerate equipment corrosion, damage electronic components, and affect machining accuracy. Without proper adaptation measures, these issues can reduce equipment efficiency and shorten its service life. By implementing targeted solutions, the stable operation of the equipment can be ensured and the impact of harsh environments can be resisted.

I. Core Points:

Control the humidity between 40% and 60% to prevent rusting and maintain equipment accuracy.

Use dehumidifiers to reduce humidity, improve machining accuracy, and extend the service life of the equipment.

Regularly clean and inspect components to ensure the equipment works properly in humid environments.

II. Temperature and Humidity Control for CNC Horizontal Machining Centers

1.Optimal Humidity Range for Equipment Operation

Maintaining an appropriate humidity level is crucial for the efficient operation of CNC horizontal machining centers. High humidity can cause oxidation and rusting, affecting the surface quality of machined parts; while low humidity increases the risk of static electricity accumulation, which may damage sensitive electronic components. To ensure the best performance of the equipment, the relative humidity (RH) should be maintained between 40% and 60%. This range can prevent corrosion, maintain the dimensional stability of materials, and minimize the risk of electrical problems. Controlling the CNC machining center within this humidity range can improve its reliability and extend its service life.

2.Advantages of Dehumidification Systems

In high-humidity environments, dehumidification systems play a key role in controlling humidity levels. These systems can remove excess moisture from the air, creating a stable environment for CNC horizontal machining centers. The main advantages of using dehumidifiers are as follows:

● Anti-corrosion: By reducing humidity, dehumidifiers help prevent rusting and oxidation of metal components.

● Improve accuracy: Stable humidity levels can avoid material expansion or contraction, maintaining machining accuracy.

● Extend equipment life: Lower humidity can reduce wear on mechanical and electronic components.

● Investing in high-quality dehumidification systems is a positive measure to protect equipment and maintain stable production quality.

3.Temperature Regulation Strategies

Temperature fluctuations can significantly affect the performance of CNC horizontal machining centers. Temperature changes can cause materials to expand or contract, leading to machining errors. To maintain accuracy, the workshop temperature should be controlled between 15°C and 25°C.

(1) The following are effective temperature regulation strategies:

● Install climate control systems: Air conditioning equipment and industrial coolers help maintain a stable temperature.

● Regularly monitor temperature: Use sensors to track temperature changes and adjust settings as needed.

● Isolate heat sources: Place the machining center away from heat-generating equipment to avoid sudden local temperature rises.

(2) The following table highlights the relationship between temperature, humidity, and production efficiency:

| Measurement Item | Correlation Value | Description |

| Productivity after ANN optimization vs. before optimization | 0.52951 | Indicates a strong correlation |

| Productivity after ANN optimization vs. relative humidity | 0.5217 | Shows a linear proportional relationship |

| Optimal humidity level | 53.6582% RH | Enables the best production value |

By implementing these strategies, a controlled environment conducive to high-precision machining and stable output can be created.

III. Strategic Equipment Layout and Planning

1.Avoid Direct Airflow and Moisture Contact

Reasonable placement of CNC horizontal machining centers can minimize their exposure to direct airflow and moisture. Airflow from HVAC systems or open windows may carry moisture particles, accelerating corrosion and damaging electronic components. To alleviate this problem, the equipment should be placed away from vents, doors, and windows. Use barriers or partitions to protect the equipment from airflow and air pollutants. This simple adjustment can reduce environmental stress and improve equipment reliability.

2.Ensure Proper Ventilation

Proper ventilation provides a clean and stable environment for horizontal CNC machining centers. Ventilation systems should maintain a stable air exchange rate to prevent moisture accumulation and remove particles from the air. Comparative studies highlight the effectiveness of air quality measurement in optimizing ventilation:

| Method | Description |

| Building ventilation assessment | Inspect rooftop air handling units and provide filter replacement schedules |

| Air sampling | Collect air samples for analysis of volatile organic compounds and particle quality |

| Endotoxin analysis | Analyze endotoxin levels in air samples to indicate bacterial presence |

| Bioaerosol sampling | Identify bioaerosols using genomic DNA analysis |

In addition, enhanced ventilation systems can improve air purification efficiency. For example:

| Variable | Measurement Method | Result |

| Effective air change rate | Ratio of room air changes to ventilation efficiency rating | Increased from 2.48 to 5.06 |

| Particle removal efficiency | Measured for different particle sizes | 51% higher than the baseline condition |

| Ventilation effectiveness | Calculated ventilation efficiency rating | Enhanced air purification effect |

These measures ensure a controlled environment conducive to precision machining and reduce maintenance needs.

3.Layout to Reduce Environmental Stress

Vibration can seriously affect the accuracy and stability of CNC horizontal machining centers. In high-humidity environments, moisture may gradually weaken structural components, and vibration may exacerbate wear. Anti-vibration pads provide a simple yet effective solution to this challenge. These pads can absorb and cushion vibrations, ensuring stable operation of the equipment and maintaining accuracy.

When choosing anti-vibration pads, priority should be given to materials with high durability and resistance to environmental factors. For example, rubber-based pads can absorb shocks while being moisture-resistant. Installing these pads under the machining center can reduce mechanical stress, lower noise, and improve the overall stability of the equipment. This basic measure not only improves machining accuracy but also extends the equipment's service life.

4.Corrosion-Resistant Materials and Coatings

In high-humidity areas, corrosion is one of the most serious threats to CNC horizontal machining centers. Moisture in the air reacts with metal surfaces, causing rusting and performance degradation. Using corrosion-resistant materials and coatings is a positive approach to address this issue.

(1) Several advancements in coating technology have been proven to effectively extend equipment life:

● Titanium dioxide nano-coated tools have a 16% longer life than uncoated tools, demonstrating the durability of advanced coatings.

● Anti-rust paints containing corrosion inhibitors can protect metal surfaces from moisture and corrosive elements.

● Coatings used in the machining industry can protect tools from extreme conditions, significantly extending their service life.

(2) The following table highlights the advantages of different types of corrosion-resistant materials and coatings:

| Evidence Type | Description |

| Protective coatings | Effectively prevent corrosion and wear, improving material durability |

| Polymer coatings | Widely used for corrosion protection due to their low conductivity and barrier properties |

| Tool life | Titanium dioxide coated tools have a 16% longer life than uncoated tools |

Adopting these materials and coatings in machining centers can ensure that key components are protected even in harsh environments. This measure not only reduces maintenance costs but also ensures long-term stable operation of the equipment.

5.Regular Maintenance and Inspection Protocols

Regular maintenance is crucial to prevent damage to CNC horizontal machining centers caused by humidity. A sound maintenance plan can ensure that CNC machine tools remain in optimal condition in high-humidity environments. Main tasks include cleaning, inspection, and replacement of components when necessary.

The following is an effective maintenance plan to follow:

● Regularly clean air filters to maintain proper airflow and prevent overheating exacerbated by humidity.

● Keep paper tape readers clean to avoid operational errors caused by moisture or debris.

● Train maintenance personnel on the structure and operating conditions of the equipment to ensure correct operation and reduce the risk of damage.

By adhering to these protocols, potential problems can be detected early and addressed before they worsen. Routine inspections also help monitor the effectiveness of anti-corrosion measures and ensure the proper operation of environmental control equipment such as dehumidifiers. This proactive approach can minimize downtime and improve the productivity of the machining center.

IV. Summary

1.Adapting CNC horizontal machining centers to high-humidity environments can ensure their optimal performance and durability.

2.Positive measures such as dehumidification, use of corrosion-resistant materials, and reasonable layout are crucial.

3.Adaptive strategies can maintain machining accuracy and stable quality.

4.Positive adjustments can reduce waste, improve productivity, and increase profits.

5.Implementing these solutions can protect the equipment and achieve long-term success.

V. Technical Q&A

Q: How to protect CNC machine tools from humidity-related corrosion?

Use corrosion-resistant coatings and materials; install dehumidifiers to control humidity levels; regularly inspect and clean equipment components to prevent rusting.

Q: What maintenance tasks should be prioritized in high-humidity environments?

Focus on cleaning air filters, inspecting electronic components, and monitoring anti-corrosion measures. Train personnel to operate the equipment correctly and identify early signs of damage.

Q: Do CNC machine tools need anti-vibration pads in humid areas?

Yes, anti-vibration pads can reduce mechanical stress and improve stability. Choose moisture-resistant pads to ensure long-term durability and stable machining accuracy.

Key words:

Previous Page

Previous Page:

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638