3-Axis vs 5-Axis Machine Tools: Which One Is More Suitable for Your Machining Needs? Understand at a Glance After Comparison

Release time:

2025-08-18

Author:

CATO

Source:

Internet

Both 3-axis and 5-axis machine tools have their own advantages. 3-axis machine tools are suitable for mass production of simple parts with lower costs, but processing complex parts requires multiple clampings, which may affect precision. 5-axis machine tools, relying on multi-axis linkage, can complete the processing of complex precision parts in one clamping, featuring high efficiency and excellent precision. Although the initial investment is higher, they have more advantages in long-term comprehensive costs. You can choose according to your needs.

In the dual competition of precision and efficiency in the manufacturing industry, traditional machining modes are facing unprecedented challenges - multi - face machining of complex parts requires repeated clamping, and the precision loss in the process of conversion is like an invisible efficiency killer. However, the emergence of 5-axis CNC machine tools has completely reconstructed the logic of precision machining: a single device can complete the whole process from blank to finished product, making "one - time clamping, perfect forming" a reality from a concept.

I Breaking through the angle limit: the flexible revolution of complex machining

| Comparison Dimension | 3 - Axis Machine Tool | 5 - Axis Machine Tool |

| Number of machining axes | Three linear axes: X, Y, Z | Three linear axes (X, Y, Z) + two rotating axes (A, C or other combinations) |

| Number of clamping times | Complex parts need multiple clamping (usually more than 3 times) | Multi - face machining can be completed with one clamping |

| Ability to machine complex parts | Only can machine regular structures such as simple planes and straight grooves, and cannot handle complex curved surfaces | Can machine complex structures such as aviation airfoils, impellers and special - shaped curved surfaces, with flexible adjustment of tool angles |

| Precision control | Repeated clamping is prone to cumulative errors (usually more than ±0.03mm) | One - time clamping reduces errors, and the precision can reach within ±0.005mm |

| Machining efficiency | Time - consuming for process conversion and long single piece machining cycle | Integrated whole - process machining, with efficiency improved by more than 40% |

| Function integration | Only supports a single milling or turning function | Can integrate turning - milling compound functions, and one device can replace multiple traditional machine tools |

| Applicable scenarios | Mass production of simple parts (such as standard parts, flat parts, etc.) | Machining of complex and precision parts in high - end manufacturing fields (aerospace, medical treatment, mold, etc.) |

This multi - degree - of - freedom machining capability has increased the machining efficiency of parts with complex spatial curved surfaces such as impellers and turbines by more than 40%. The practice of an aviation manufacturing enterprise shows that after adopting the 5 - axis machining center, the machining processes of the engine casing have been reduced from 13 to 5, the production cycle of a single piece has been shortened from 72 hours to 28 hours, and the dimensional accuracy is controlled within ±0.005mm.

II Turning - milling compound: making one device equal to a workshop

When the machining demand involves both turning and milling, the traditional mode requires repeated transfer of workpieces between the lathe and the machining center, which is not only time - consuming and labor - intensive, but also may cause cumulative errors due to datum conversion. The 5 - axis linkage turning - milling compound center has completely broken this process barrier - its spindle can switch between turning mode and milling mode, and with dozens of different types of tools in the tool magazine, it can complete the whole process from cylindrical turning, end face boring to special - shaped contour milling on the same platform.

The case of a medical device enterprise is quite representative: in the past, artificial joint parts needed to go through 6 processes such as rough turning on a lathe, slotting on a milling machine, and fine grinding on a grinder. After introducing the turning - milling compound equipment, all machining can be completed with a single clamping, which not only increases the production efficiency by 3 times, but also increases the product qualification rate from 82% to 99.5% by avoiding multiple positioning. With the support of the intelligent automatic tool change system, the equipment can realize 24 - hour continuous operation, and the daily output is equivalent to the sum of 3 traditional machine tools.

III Rigidity and intelligence: the double guarantee behind precision

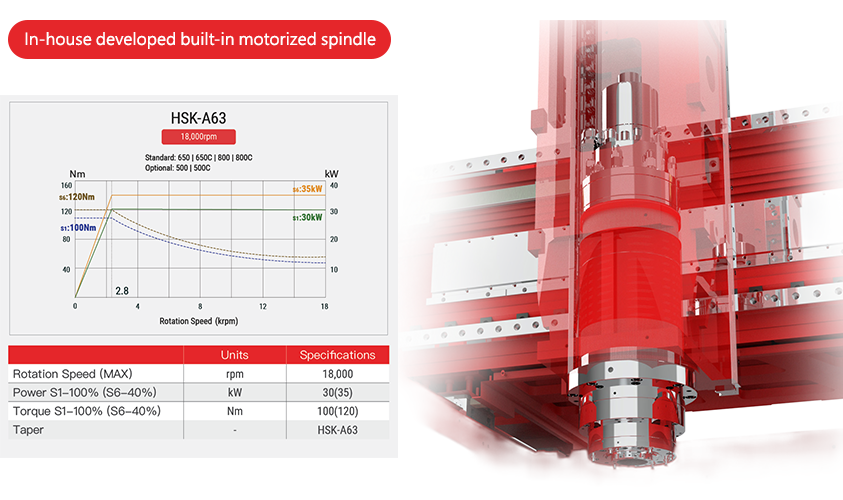

The high precision of 5 - axis machining is not accidental, but based on the double cornerstones of "rigid structure + intelligent control". The machine tool bed is cast with integral cast iron and undergoes aging treatment to eliminate internal stress, so that the amplitude is controlled below 0.002mm during high - speed cutting; the spindle unit is equipped with ceramic bearings and an oil mist lubrication system, with a maximum speed of 18000rpm, which can maintain stable output even when machining high - strength alloy materials.

The advanced numerical control system is like the "brain" of the equipment, which collects 16 process parameters such as cutting force and temperature in real time, and dynamically compensates for errors caused by thermal deformation through an algorithm model. When tool wear is detected, the system will automatically adjust the feed speed and issue a tool change warning to ensure that the cutting amount of each tool is accurately controllable. The test data of a mold enterprise shows that after continuously machining 500 stainless steel parts, the dimensional consistency is still maintained within 0.01mm, far exceeding the industry average level.

IV Full scene coverage: from precision small parts to giant structures

In response to the machining needs of different industries, 5 - axis machine tools have formed a complete product matrix:

Vertical 5 - axis machining center: covers an area of only 8㎡, the spindle taper hole adopts HSK - A63 specification, suitable for machining precision cavity parts in 3C products, with a repeat positioning accuracy of ±0.003mm;

Gantry type 5 - axis machine tool: the worktable can bear a load of up to 50 tons, and the X - axis stroke is up to 12 meters, specially used for machining large structural parts such as wind power hubs and marine engine cylinder blocks;

Turning - milling compound unit: equipped with a power turret and Y - axis function, it can not only machine shaft parts with a diameter of 500mm, but also complete the milling of complex curved surfaces, and is an ideal machining equipment for automobile transmission parts.

These machine types have been widely used in high - end manufacturing fields such as aerospace, new energy, and medical devices. The motor shell machined by a new energy enterprise using 5 - axis machine tools has improved the motor efficiency by 2.3 percentage points due to its form and position tolerance control ability.

V Technical Q & A: Deciphering the core logic of 5 - axis machining

Q: Why can 5 - axis machine tools reduce the number of clamping times?

A: Through the linkage of double rotating axes, the tool can approach the workpiece from any angle. The parts that originally needed to be turned over to machine can now be completed by adjusting the angle of the rotating axis, realizing "one - time clamping, multi - face machining".

Q: Will the turning - milling compound function affect the machining accuracy?

A: On the contrary, integrated machining eliminates the datum error in the process of process conversion. Taking crankshaft machining as an example, the cumulative error of the traditional method is about 0.03mm, while that of turning - milling compound machining can be controlled within 0.01mm.

Q: Is 5 - axis machine tool suitable for small - batch production?

A: It is very suitable. The flexible machining capacity of 5 - axis machine tools enables them to quickly switch machining schemes. The practice of an auto parts enterprise shows that in the production of multi - variety and small batches (50 - 100 pieces), the comprehensive cost of 5 - axis machine tools is 28% lower than that of traditional equipment.

From eliminating errors to improving efficiency, from function integration to intelligent upgrading, 5 - axis CNC machine tools are redefining the standards of precision machining. When a single device can complete the work that used to require an entire production line, and when the machining cycle of complex parts is reduced by more than half, the efficiency revolution in the manufacturing industry has already arrived. Choosing a suitable 5 - axis machining scheme is not only the update of production equipment, but also the upgrading of the manufacturing mode - this may be the key to opening the door to future intelligent manufacturing.

▷ Learn more: https://en.catocnc.com/products_details/8.html

▷ Technical consultation: +86 138-2920-2050

Key words:

CATO CNC ,5-axis horizontal swing head machining center,5-axis fixed beam gantry machining center ,high-speed vertical machining center ,machining center manufacturer ,CNC machining center ,5-axis bridge-type machining center ,5-axis overhead crane machining center ,5-axis moving column vertical machining center ,5-axis vertical machining center ,5-axis horizontal cradle machining center ,3-axis machine tool,5-axis machine tool,machine tool comparison ,machining equipment selection,precision machining machine tool,machine tool efficiency difference,machine tool cost comparison

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638