CATO's A-Series Five-Axis Machines: Revolutionizing NEV Manufacturing with 85% Efficiency Boost

Release time:

2025-06-24

Author:

Source:

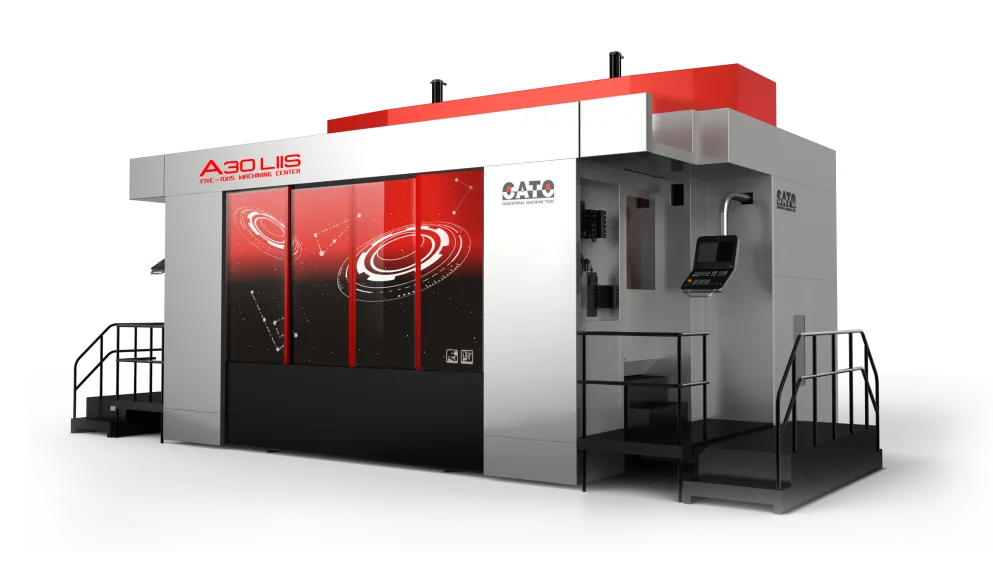

As the NEV industry reaches a critical inflection point with 35% customization rates (McKinsey Q2 Report) coinciding with China's MIIT "Smart Manufacturing Enhancement Year" policy initiative, CATO's A-Series five-axis horizontal machining centers are quietly transforming manufacturing paradigms through three technological revolutions.

As the NEV industry reaches a critical inflection point with 35% customization rates (McKinsey Q2 Report) coinciding with China's MIIT "Smart Manufacturing Enhancement Year" policy initiative, CATO's A-Series five-axis horizontal machining centers are quietly transforming manufacturing paradigms through three technological revolutions.

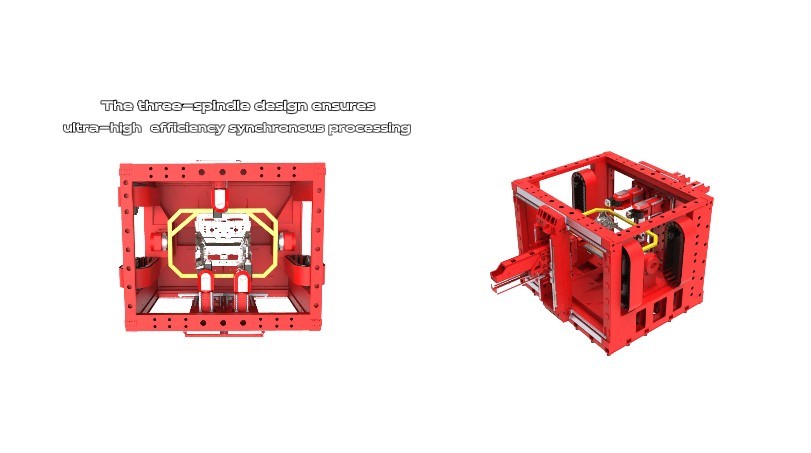

This equipment, featuring CATO's proprietary five-axis technology, has emerged as a leader in green intelligent manufacturing. Facing the triple challenges of precision, efficiency and stability demands, CATO's innovative triple-spindle design delivers 85% higher efficiency than dual-spindle systems, setting new benchmarks for precision machining of NEV components. Through mechanical symmetry optimization, this breakthrough achieves micrometer-level spindle stability, eliminating precision barriers for battery casings and motor rotors.

If traditional machine transmissions resemble a "symphony of gears and belts," CATO's linear motor direct-drive technology composes a "silent rhapsody" for Industry 4.0.The X/Y/Z axes are fully equipped with linear motors, which not only eliminate the energy loss and backlash errors inherent in mechanical transmission systems, This technology significantly improves complex surface machining for lightweight aluminum NEV parts. Notably, its torque motor direct-drive maintains whisper-quiet operation at high speeds - embodying green manufacturing principles in noise reduction.

Addressing both sustainability and efficiency, CATO's high-rigidity lightweight design delivers groundbreaking solutions. While competitors struggle with multi-process switching delays, CATO's five-axis cradle worktable enables "complete multi-surface machining in single clamping" - from front/back transitions to multi-angle cutting. Combined with zero-wear torque motor technology, it reduces processing cycles to one-third of traditional methods.

As global attention turns to Chinese smart manufacturing, CATO is redefining precision manufacturing standards with its five-axis technology - where compromise doesn't exist, only relentless pursuit of ultimate efficiency and stability.

Key words:

Previous Page

Previous Page:

Latest information

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638