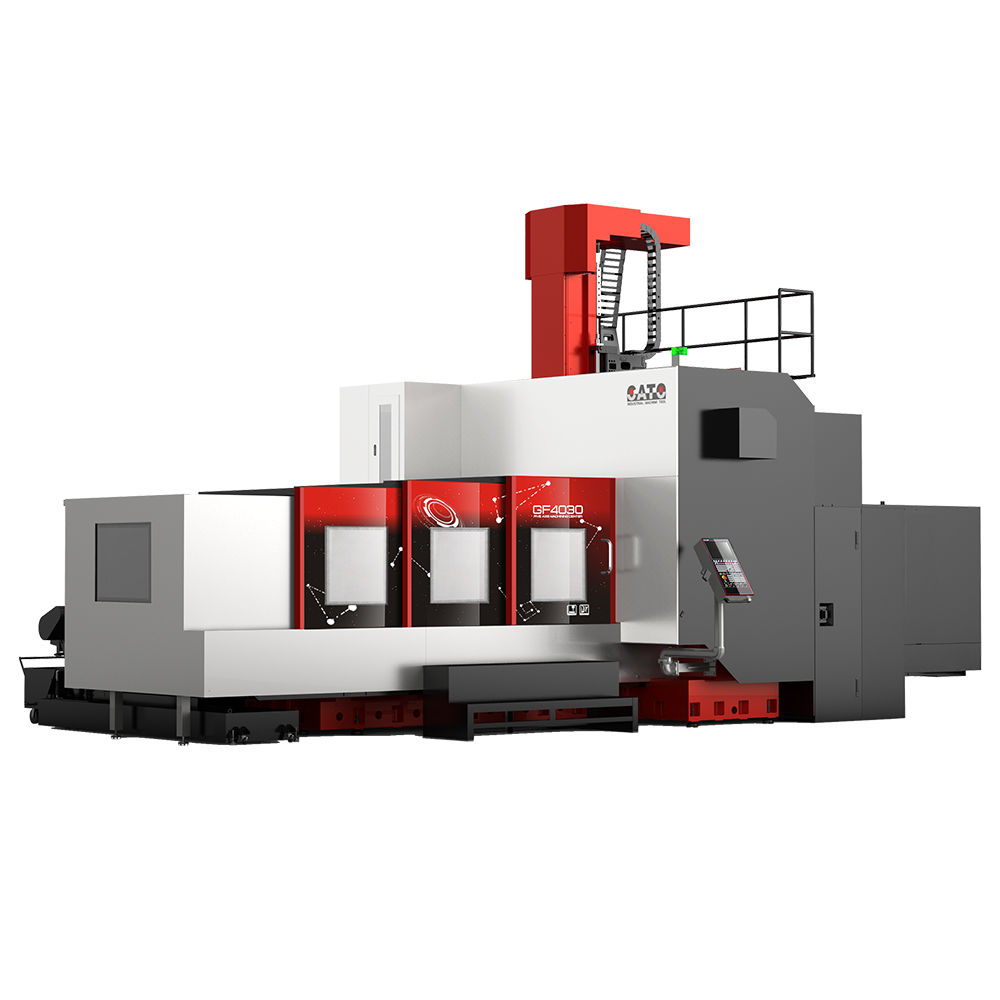

GF4030-5X

Five-axis fixed beam portal type machining center

■ Titling X-axis structure design for high-speed and high-precision positioning ■ U-type saddle structure design ensures high-rigidity machining ■ One-piece double column structure design for high rigidity and stable machining ■ In-house developed: motorized spindle, swiveling and rotary table, CNC control system, automatic tool magazine

Product Features

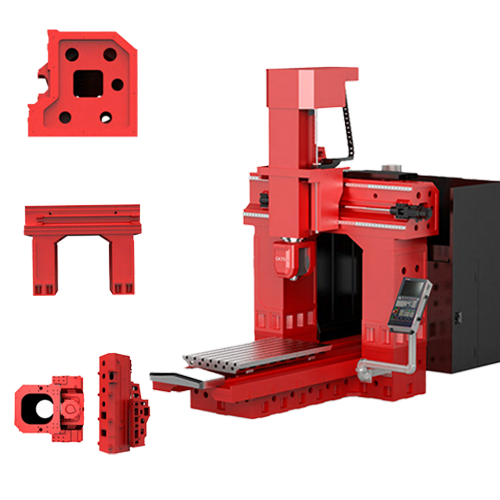

High-Rigidity Structure Design

• T-shape structure design and ladder-type structure design of guideway on X-axis, combined with light-weight moving components can achieve quick response and high-precision machining.

• Featuring a column-moving structure, the machine enables precise movement of the cutting tool on X, Y, Z axis, rotation of the workpiece on A, B axis, and high-efficiency 5-axis machining capabilities.

High-Rigidity Ball Screws for Transmission

• High Rigidity

• High Efficiency

Meticulous Hand Scrapping

• Mating surface above 90%

• Setting the foundation for high-precision and stable machining

High-Rigidity Roller Type Linear Guideway

• Ensure high-rigidity machining

• Ensure high-precision machining

High-Precision Linear Encoder and Angle Encoder

• Ensure high-rigidity machining

• Ensure high-precision machining

Product Specification

Specifications | Units | GF4030-5X |

Working travels |

|

|

Working travels X-/Y-/Z-axis | mm | 4000x 3000 x 1000 |

Distance from spindle nose to A-axis rotation center | mm | -100-900 |

Linear axes |

| |

Feedrate X/Y/Z-axis | m/min | 30 /30 /30 |

Rapid traverse | mm/min | 1~12000 |

| Guideway on X | mm | 45/4roller |

| Guideway on Y | mm | 65roller |

| Guideway on Z | mm | 65roller |

| Screw on X | mm | Ø80 x 20 |

| Screw on Y | mm | Ø63 x 16 |

| Screw on Z | mm | Ø63 x 12 |

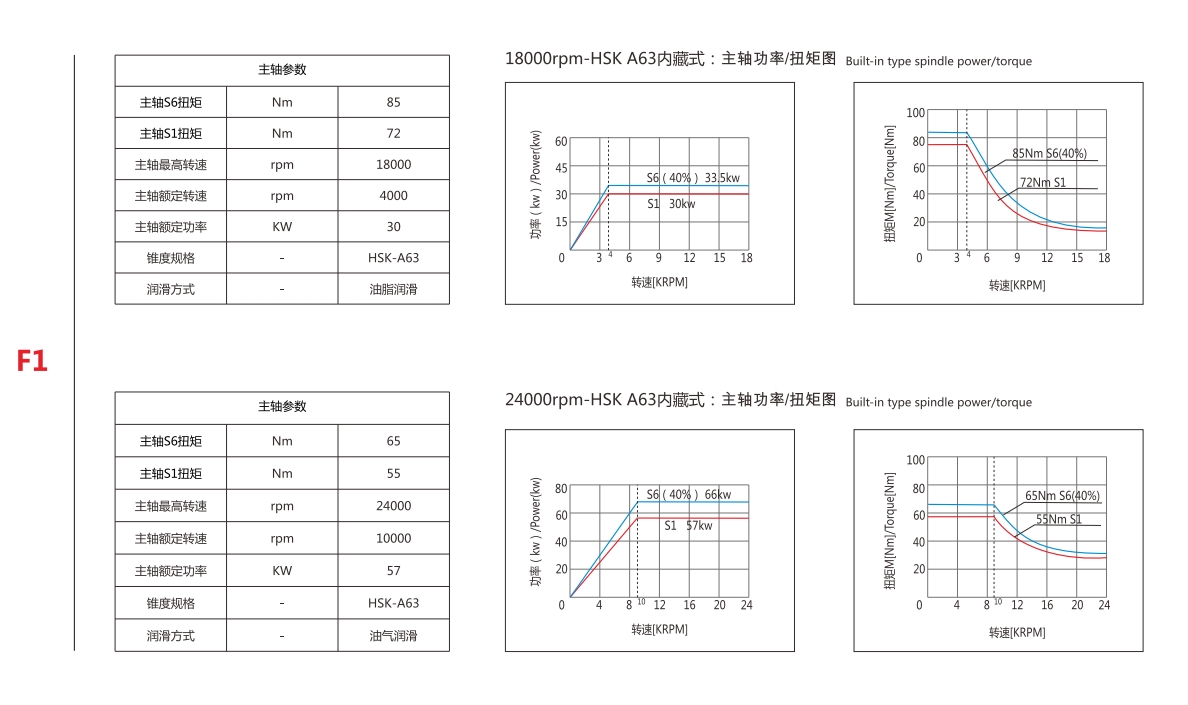

Spindle |

|

|

Spindle taper | - | A63 |

Rotation speed(max) | rpm | 18000 |

Power | kW | 70 / 75 |

Torque | Nm | 350 / 450 |

Rotary table |

| |

Table diameter | mm | 4000 x 2000 |

Table loading | kg | 20000 |

Tool magazine |

|

|

Capacity | pcs | 24 |

Max diameter | mm | 250 |

Max length | mm | 400 |

Max weight | kg | 15 |

Tool change time | sec | 5 |

Accuracy X-/Y-/Z-axis |

|

|

Positioning accuracy | arc.sec / mm | ±0.005/300 |

Repeated positioning accuracy | arc.sec / mm | ±0.003/300 |

Others |

|

|

Air requirement | kg/cm2 | ≥6 |

Air volume | mm3 / min | ≥0.5 |

| Machine weight | ton | 50 |

Spindle | Head

Product Standard

| GF2020-5X | GF3020-5X | GF4020-5X |

CATO C80 Plus | √ | √ | √ |

HEIDENHAIN TNC640 | ▲ | ▲ | ▲ |

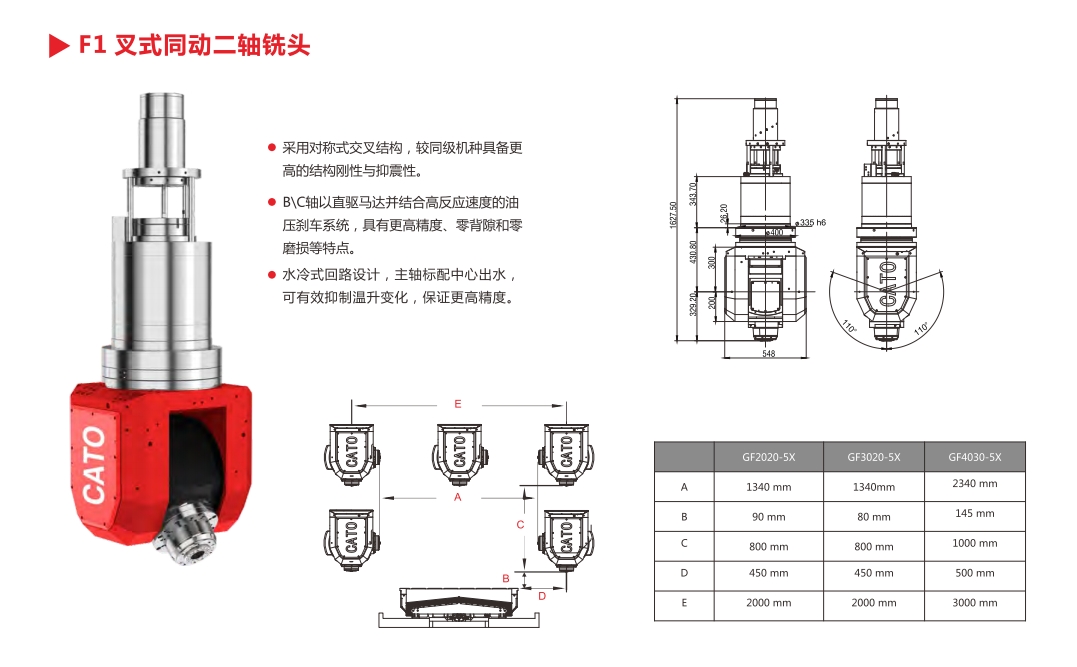

| F1 Fork-type two-axis milling head | √ | √ | ▲ |

| F2 Fork-type two-axis milling head | ▲ | ▲ | -- |

| F3 Orthogonal milling head | ▲ | ▲ | -- |

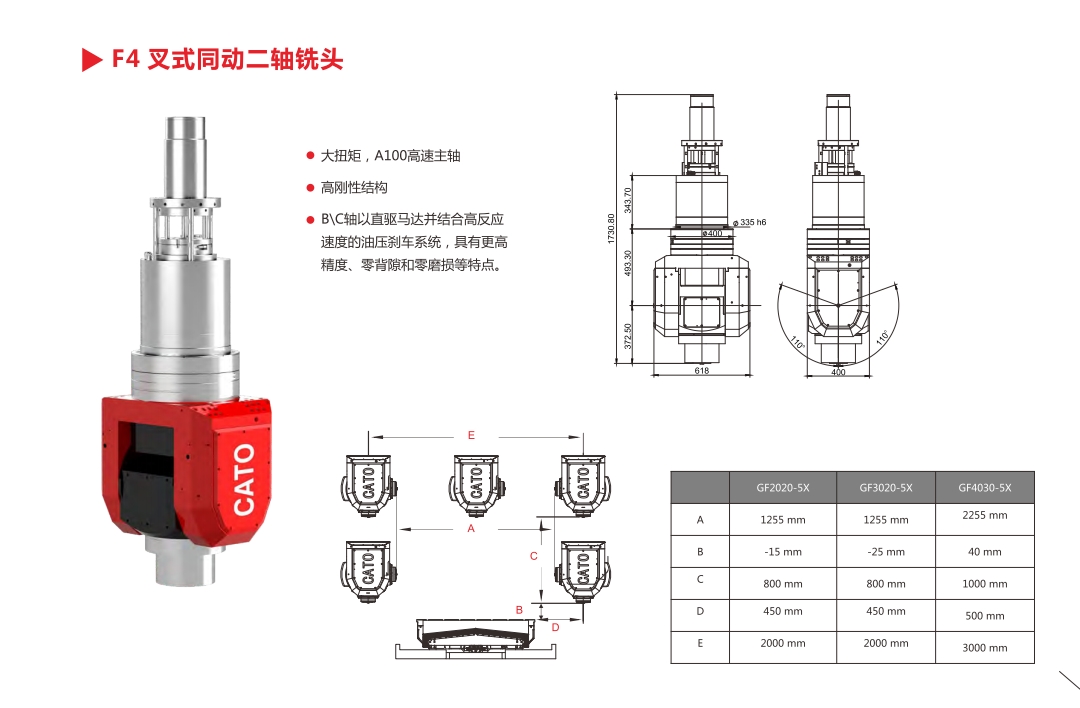

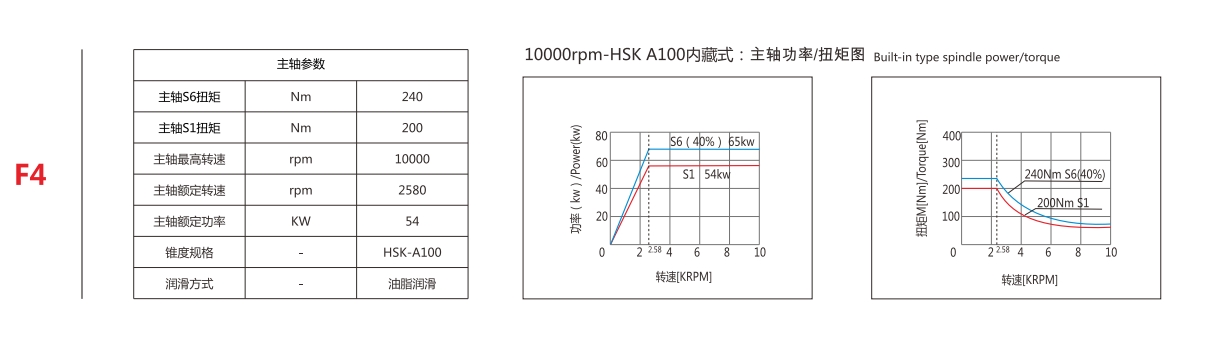

| F4 Fork-type two-axis milling head | ▲ | ▲ | ▲ |

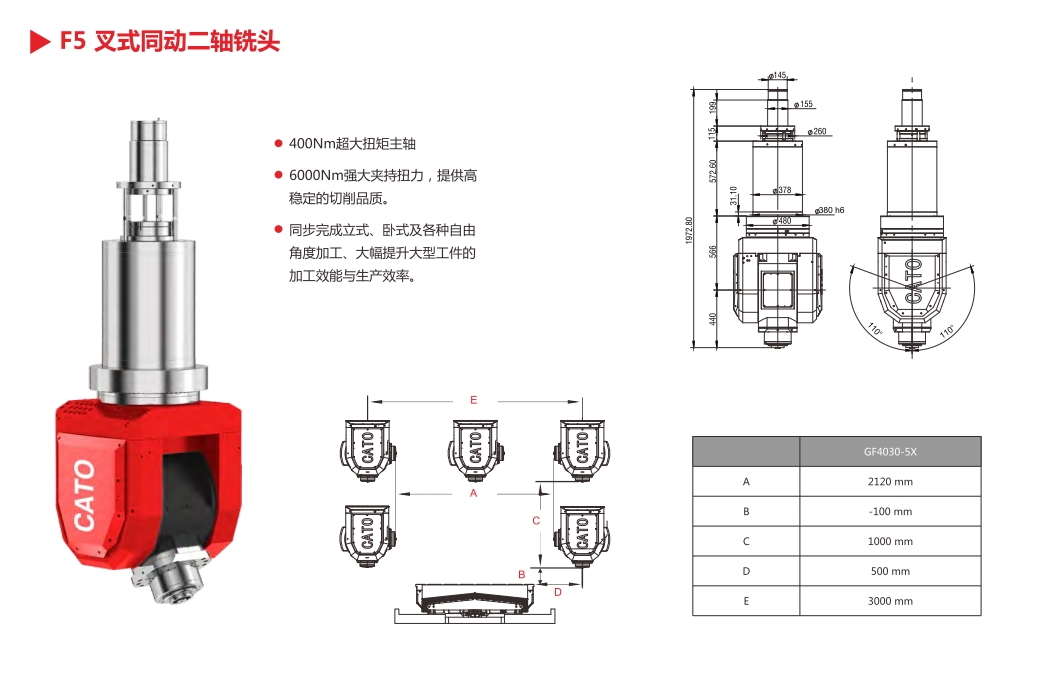

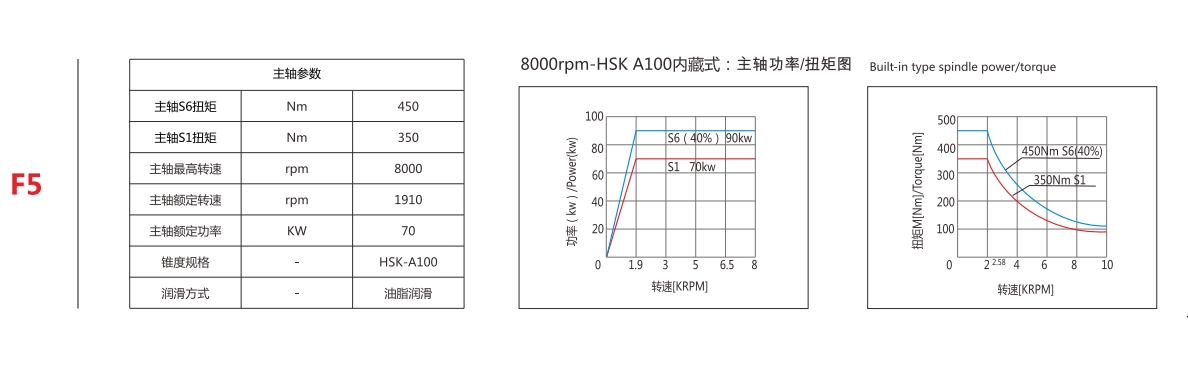

| F5 Fork-type two-axis milling head | -- | -- | √ |

| 24T arm-type tool magazine | √ | √ | √ |

| 36T arm-type tool magazine | ▲ | ▲ | ▲ |

| 40T arm-type tool magazine | ▲ | ▲ | ▲ |

| Motorized spindle temperature control device | √ | √ | √ |

| LED work light | √ | √ | √ |

| Portable manual pulse generator | √ | √ | √ |

| Tool setter | √ | √ | √ |

| LED 3-color warning light | √ | √ | √ |

| Automatic lubricator | √ | √ | √ |

| Fully enclosed protection cover | √ | √ | √ |

| Coolant nozzle | √ | √ | √ |

| Through Spindle Coolant(TSC) | √ | √ | √ |

| Chip flooding disposal system | √ | √ | ▲ |

| Spiral chip conveyor | ▲ | ▲ | √ |

| Drum chain chip conveyor | √ | √ | √ |

| Drum scraper chip conveyor | ▲ | ▲ | ▲ |

| Compound chip conveyor | ▲ | ▲ | ▲ |

| Air filter apparatus | √ | √ | √ |

| Tool kits | √ | √ | √ |

| Technical manual | √ | √ | √ |

| Linear encoder | ▲ | ▲ | ▲ |

| Online detection system | ▲ | ▲ | ▲ |

| Laser tool setter | ▲ | ▲ | ▲ |

| Broken tool detection | ▲ | ▲ | ▲ |

| Immersion coolant cooling system | ▲ | ▲ | ▲ |

| Power sourc manostat | ▲ | ▲ | ▲ |

| Oil mist collector | ▲ | ▲ | ▲ |

√ Standard ▲ Option -- Not available

Machining Application

Torque Housing

CD Pillar

Die Casting Body Part

Die Casting Batterty Housing

Product Video

If you are interested in this product, please complete the following information submitted to us, we will arrange experts to contact you as soon as possible!

Online Message

Leave your contact information and needs, we will arrange for professionals to contact you

Quick Navigation

Contact Us

Add.: No.1, Dongye Road, Houjie Town, Dongguan City, Guangdong Province, China

Tel: +86-769-38825288

WeChat: CATO54321

Fax: +86-769-38825138

E-mail: marketing@catocnc.cn

Web: http://www.catocnc.com

Service Hotline: +86-400-680-6638